Saddle Stitch Sewing Machine for Leathercraft and Upholstery Projects

The Evolution and Impact of the Saddle Sewing Machine

In the world of sewing, the saddle sewing machine stands out as a remarkable innovation that has transformed the production of leather goods, particularly in the crafting of saddles and various other heavy-duty items. Its design, functionality, and efficiency have made it an essential tool for leatherworkers and manufacturers alike, revolutionizing traditional methods and paving the way for modern craftsmanship.

Historical Context

The origins of sewing machines can be traced back to the early 19th century, when inventors began to experiment with mechanizing the sewing process. However, it wasn't until the introduction of specific machines designed for leather that the industry truly began to flourish. The saddle sewing machine was developed to handle the unique challenges posed by thicker materials such as leather. Thanks to its robust construction and specialized features, it became an invaluable asset for artisans who sought to create durable and functional leather products.

Design Features

The saddle sewing machine is characterized by its heavy-duty build, which allows it to sew multiple layers of leather effortlessly. One of the key features of these machines is the walking foot mechanism, which ensures that the fabric is fed evenly through the machine, preventing any slipping or misalignment during the sewing process. This is crucial when working with leather, as uneven stitching can compromise the integrity of the finished product.

Additionally, saddle sewing machines are equipped with powerful motors that can handle thick threads, which are essential for creating the strong seams typical of leather goods. The needle system is also designed to penetrate heavy materials without breaking, allowing for precise and consistent stitching. Many modern saddle sewing machines come with various stitch options, enabling artisans to customize their work according to specific design requirements.

Applications in Leathercraft

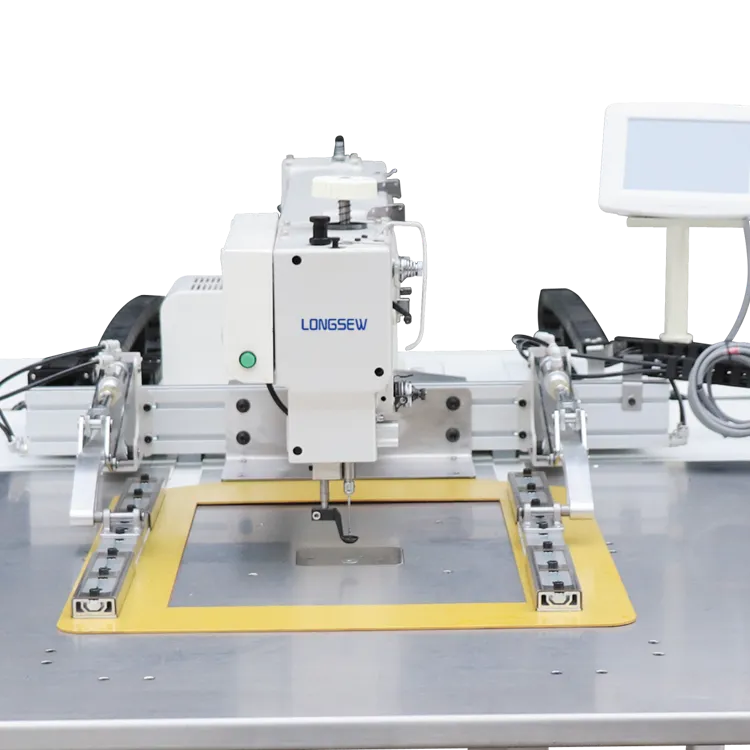

saddle sewing machine

Saddle sewing machines are not limited to saddle making, despite their name. They are widely used in the production of a variety of leather goods, including bags, belts, wallets, and upholstery. The ability to sew through heavy materials with precision has made these machines suitable for both small-scale artisanal productions and large-scale manufacturing operations.

The flexibility of the saddle sewing machine allows leatherworkers to experiment with intricate designs and patterns. They can create beautiful, handcrafted items that showcase their craftsmanship while also ensuring that the products are durable and functional. The machine's ability to handle decorative stitching adds an aesthetic quality to the pieces, catering to an audience that appreciates both form and function.

The Modern Saddle Sewing Machine

In recent years, technological advancements have further improved the saddle sewing machine's capabilities. Many machines now feature computerized systems that enhance precision and efficiency. These machines can automatically adjust tension, stitch length, and speed, allowing for a higher level of control over the sewing process. This modernization has made it easier for both experienced leatherworkers and beginners to create high-quality products.

Sustainability has also become a focal point in the leather industry, and modern saddle sewing machines play a role in this shift. With the ability to produce stronger, long-lasting products, these machines contribute to a decrease in waste generated by poorly made items. As artisans focus on quality over quantity, the saddle sewing machine becomes a symbol of a return to craftsmanship and thoughtful production.

Conclusion

The saddle sewing machine has made a profound impact on the leatherworking industry, providing artisans with the tools necessary to create beautiful and durable products. Its robust design, specialized features, and versatility have transformed the way leather goods are produced. As the industry continues to evolve, the saddle sewing machine remains a testament to the blend of traditional craftsmanship and modern innovation, ensuring that the art of leatherworking thrives for generations to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025