Jan . 17, 2025 05:10

Back to list

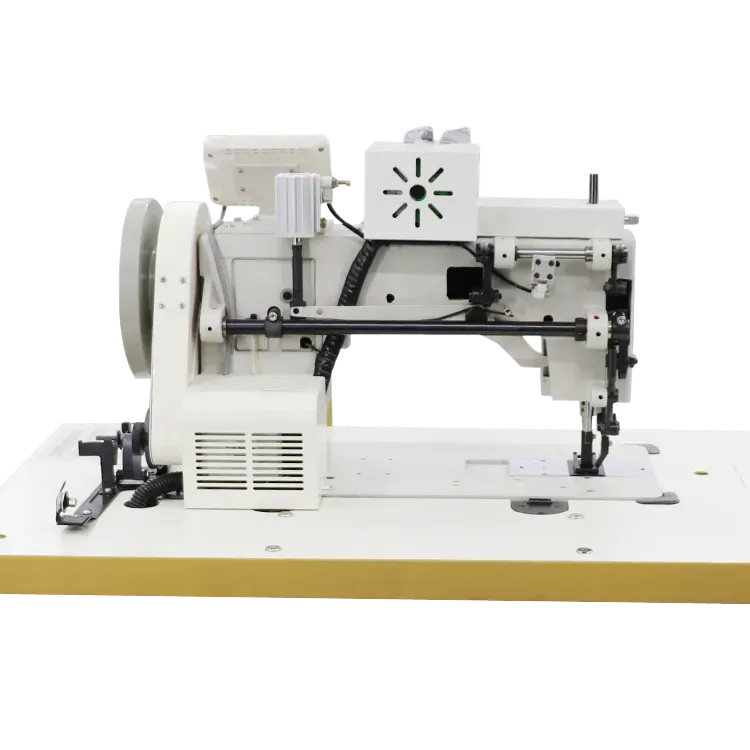

FIBC Bag / Jumbo Bag / Bulk Bag Single Needle Lock Stitch Top & Bottom Feeding Sewing Machine GSC367/GSC367TD /GSC367TDZ/ GSC367-L.

The needle lockstitch machine stands as a cornerstone in the realm of modern sewing, epitomizing the marriage between precision and durability. As an evolution of traditional sewing machines, the needle lockstitch machine offers a range of features that address the needs of both industrial and domestic users. Its designed intricacy ensures that it produces clean, professional-grade stitches that are essential for products ranging from haute couture to durable upholstery. Having spent over two decades in the sewing equipment industry, I've seen firsthand the transformative impact of this machine on production efficiency and garment quality.

Trustworthiness in a needle lockstitch machine is often reflected in its brand reputation and user reviews. Established brands typically offer models that have been rigorously tested for safety and durability. Warranty and after-sales service are additional considerations that instill confidence and assure continuous support for the lifespan of the machine. For instance, companies known for their customer support and spare part availability are generally preferred in a market that values reliability. In the global context, sustainability is an increasingly significant factor. The needle lockstitch machine contributes positively to this movement by reducing fabric waste through its precise cutting and stitching capabilities. This not only conserves materials but also supports environmental initiatives aimed at reducing the textile industry's carbon footprint. From personal experience, training on a needle lockstitch machine significantly enhances one's skill set, making operators more valuable in any industrial setting. Mastery of this machine offers career advancement opportunities and the potential to oversee more complex projects, elevating an operator's expertise and authority within their field. In conclusion, the needle lockstitch machine is a testament to engineering excellence, combining efficiency, precision, and resilience. Its wide applicability across different fabric types and stitching requirements makes it an indispensable tool for both novice and expert sewists. Investing in a quality machine and comprehensive training assures not only superior product outcomes but also reinforces the integrity and trustworthiness of production processes. Taking these points into account, businesses and individuals looking to optimize their sewing capabilities should consider the tangible benefits offered by investing in a needle lockstitch machine. The confluence of technology and tradition in these machines ensures they remain an integral component in the ever-evolving textile industry.

Trustworthiness in a needle lockstitch machine is often reflected in its brand reputation and user reviews. Established brands typically offer models that have been rigorously tested for safety and durability. Warranty and after-sales service are additional considerations that instill confidence and assure continuous support for the lifespan of the machine. For instance, companies known for their customer support and spare part availability are generally preferred in a market that values reliability. In the global context, sustainability is an increasingly significant factor. The needle lockstitch machine contributes positively to this movement by reducing fabric waste through its precise cutting and stitching capabilities. This not only conserves materials but also supports environmental initiatives aimed at reducing the textile industry's carbon footprint. From personal experience, training on a needle lockstitch machine significantly enhances one's skill set, making operators more valuable in any industrial setting. Mastery of this machine offers career advancement opportunities and the potential to oversee more complex projects, elevating an operator's expertise and authority within their field. In conclusion, the needle lockstitch machine is a testament to engineering excellence, combining efficiency, precision, and resilience. Its wide applicability across different fabric types and stitching requirements makes it an indispensable tool for both novice and expert sewists. Investing in a quality machine and comprehensive training assures not only superior product outcomes but also reinforces the integrity and trustworthiness of production processes. Taking these points into account, businesses and individuals looking to optimize their sewing capabilities should consider the tangible benefits offered by investing in a needle lockstitch machine. The confluence of technology and tradition in these machines ensures they remain an integral component in the ever-evolving textile industry.

Latest news

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025