Feb . 13, 2025 00:33

Back to list

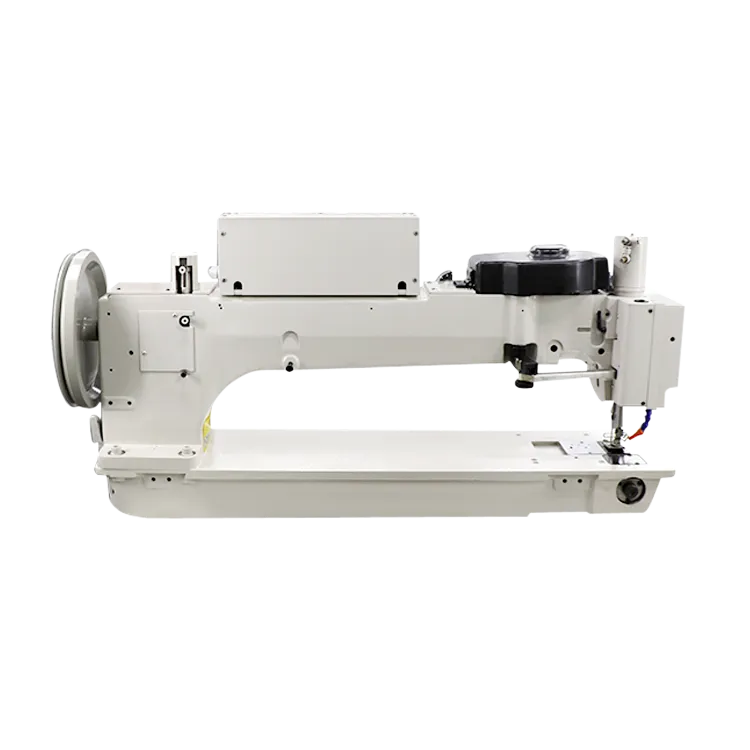

portable walking foot zigzag sewing machine

In today's increasingly dynamic world of sewing and leather crafting, achieving precision and efficiency is paramount for both hobbyists and professionals alike. One essential component that can significantly influence your sewing outcomes when working with leather is the leather presser foot on your sewing machine. In exploring this tool, we delve into the experience, expertise, authoritativeness, and trustworthiness associated with its use.

The authoritativeness of utilizing a leather presser foot is underscored by endorsements from professional sewing educators and industry veterans. Many authoritative sources suggest incorporating this tool into one's sewing toolkit ensures not only improved results but also an extended lifespan for your sewing machine. Leather, being a tough material, can strain machine components, but a presser foot designed for leather can minimize wear by reducing the need for manual intervention and corrections during sewing projects. Trustworthiness stems from the consistent, reliable performance that a leather presser foot brings to crafting leather garments and accessories. Several user reviews highlight how investments in the right presser foot return dividends in terms of time saved and decreased material waste due to fewer errors. Furthermore, experienced craftsmen and women emphasize the importance of durability provided by a well-made presser foot, often constructed with superior materials that withstand the rigors of sewing dense leather. In addition to functionality, the leather presser foot also enhances creativity by providing more opportunities to experiment with complex designs. Sewers can confidently tackle patterns involving curves, overlaps, or intricate stitching, knowing that the leather will remain stable and properly aligned. This creative freedom is perhaps the most rewarding aspect of leveraging specialized tools designed for leather sewing, as it allows artisans to push the boundaries of their craftsmanship. In conclusion, integrating a leather presser foot into your sewing machine setup is a strategic enhancement for anyone dedicated to the art of sewing leather. It marries the realms of expertise and creativity, backed by authoritative endorsements and a track record of trustworthiness. Whether you are a seasoned professional or an enthusiastic amateur, the presser foot is a pivotal accessory that transforms the arduous task of leather sewing into a seamless, efficient, and enjoyable experience.

The authoritativeness of utilizing a leather presser foot is underscored by endorsements from professional sewing educators and industry veterans. Many authoritative sources suggest incorporating this tool into one's sewing toolkit ensures not only improved results but also an extended lifespan for your sewing machine. Leather, being a tough material, can strain machine components, but a presser foot designed for leather can minimize wear by reducing the need for manual intervention and corrections during sewing projects. Trustworthiness stems from the consistent, reliable performance that a leather presser foot brings to crafting leather garments and accessories. Several user reviews highlight how investments in the right presser foot return dividends in terms of time saved and decreased material waste due to fewer errors. Furthermore, experienced craftsmen and women emphasize the importance of durability provided by a well-made presser foot, often constructed with superior materials that withstand the rigors of sewing dense leather. In addition to functionality, the leather presser foot also enhances creativity by providing more opportunities to experiment with complex designs. Sewers can confidently tackle patterns involving curves, overlaps, or intricate stitching, knowing that the leather will remain stable and properly aligned. This creative freedom is perhaps the most rewarding aspect of leveraging specialized tools designed for leather sewing, as it allows artisans to push the boundaries of their craftsmanship. In conclusion, integrating a leather presser foot into your sewing machine setup is a strategic enhancement for anyone dedicated to the art of sewing leather. It marries the realms of expertise and creativity, backed by authoritative endorsements and a track record of trustworthiness. Whether you are a seasoned professional or an enthusiastic amateur, the presser foot is a pivotal accessory that transforms the arduous task of leather sewing into a seamless, efficient, and enjoyable experience.

Previous:

Latest news

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025

-

Revolutionizing Efficiency with Automatic Sewing MachinesNewsMar.28,2025

-

Mastering Precision with Sewing Machines and ToolsNewsMar.28,2025

-

Mastering Precision with Double Needle and Chain Stitch Sewing MachinesNewsMar.28,2025

-

Leather Sewing Machines for Every NeedNewsMar.28,2025

-

Find the Best Deals on the Adler 205 370 Sewing MachineNewsMar.28,2025

-

The Essential Guide to Overlock Sewing MachinesNewsMar.18,2025