High-Quality Leather Sewing Machine Belts for Durable Performance

Understanding Leather Sewing Machine Belts

Leather sewing machine belts play a crucial role in the performance and efficiency of sewing machines, particularly in upholstery and leatherworking. These belts are specifically designed to connect the motor to the sewing machine mechanism, ensuring smooth and reliable operation. Understanding the types, maintenance, and benefits of these belts can enhance your sewing experience, especially when working with tougher materials like leather.

Types of Leather Sewing Machine Belts

When it comes to leather sewing machine belts, there are primarily two types flat belts and round belts. Flat belts are made of a wide, flat piece of leather, which offers a sturdy connection between the motor and the machine. These belts are typically used in older machines and industrial models, where stability and power transmission are critical. On the other hand, round belts are circular and provide flexibility in movement, making them suitable for contemporary sewing machines.

Benefits of Using Leather Belts

One of the most significant advantages of using leather for sewing machine belts is its durability. Leather belts can endure the rigors of constant operation without losing their firmness or shape. This resilience is particularly important in sewing leather, fabric, or other heavy materials, where a strong belt can significantly affect the quality of the stitch and the machine's overall performance. Additionally, leather has a natural grip that enhances traction, reducing slippage and ensuring consistent sewing speed.

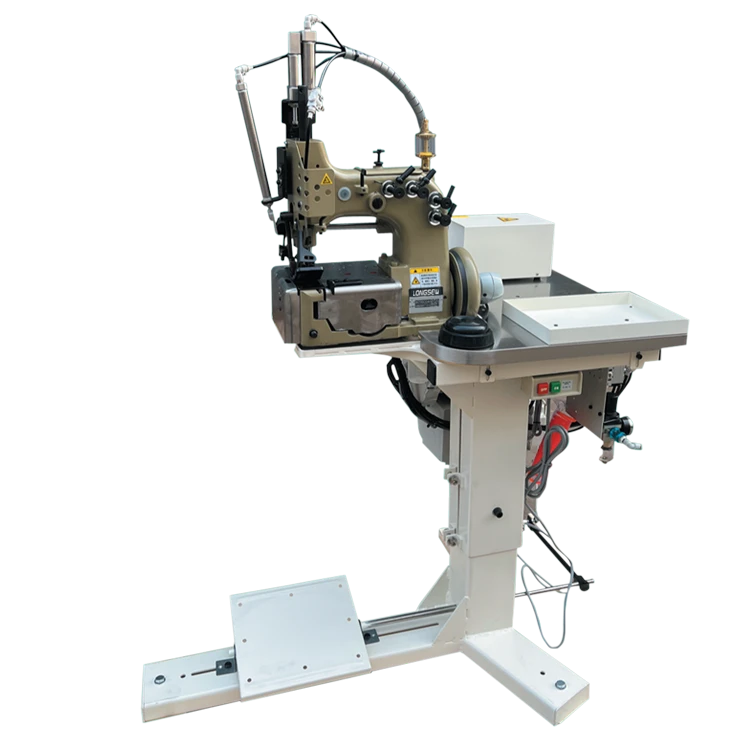

leather sewing machine belts

Furthermore, leather belts are often adjustable, providing the ability to fit various machine models. This adaptability simplifies the replacement process, making it easy to find a suitable belt that meets the specific needs of different sewing tasks. Leather belts also have a classic aesthetic, which appeals to many sewists who appreciate traditional tools.

Maintenance of Leather Sewing Machine Belts

Proper maintenance of leather sewing machine belts is essential for longevity and optimal performance. Regular checks for wear and tear can prevent more significant issues down the line. If you notice cracks, fraying, or weakening, it may be time for a replacement. Additionally, periodic conditioning with leather care products can help maintain the belt's flexibility and prevent drying out.

Maintaining proper tension is also crucial. A belt that is too loose can lead to slippage, while one that is too tight can cause undue strain on the motor and the machine components. Adjusting the belt tension as needed will contribute to the smooth operation of your sewing machine.

In conclusion, leather sewing machine belts are an indispensable component for anyone involved in leatherworking or sewing demanding fabrics. Their durability, flexibility, and ease of adjustment make them a popular choice. With proper maintenance and care, these belts can ensure your sewing machine operates at peak performance, helping you create beautiful and lasting projects. Whether you're a hobbyist or a professional, investing in a quality leather belt can make all the difference in your sewing endeavors.

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025

-

Sail Making Machine: Heavy-Duty Stitching for Industrial and Marine NeedsNewsJul.18,2025

-

Sling Sewing Machine: The Backbone of Heavy-Duty FabricationNewsJul.18,2025

-

Leather Sewing Machine: Precision for Heavy-Duty StitchingNewsJul.18,2025

-

Big Bag Sewing Machine: Powering the Future of Bulk PackagingNewsJul.18,2025

-

FIBC Sewing Machine: Essential Equipment for Bulk Bag ProductionNewsJul.18,2025

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025