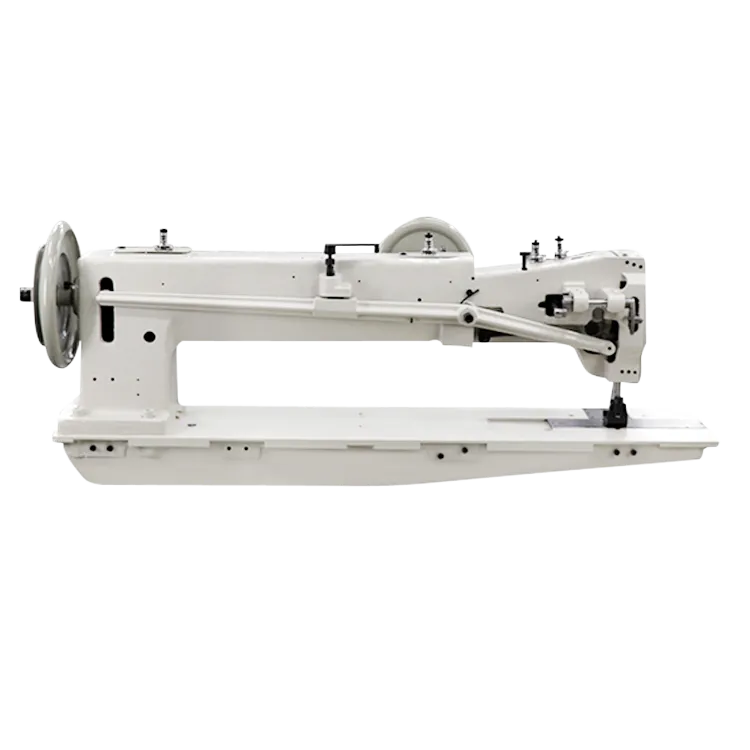

industrial single needle lock stitch sewing machine with needle guard

The Industrial Single Needle Lock Stitch Sewing Machine with Needle Guard

In the world of textile manufacturing, the choice of sewing machines is paramount to achieving efficiency, quality, and safety. Among the various options available, the industrial single needle lock stitch sewing machine stands out as a keystone of garment production. With the added feature of a needle guard, this machine not only enhances performance but also elevates workplace safety, making it an ideal choice for numerous sewing applications.

Industrial single needle lock stitch sewing machines are designed for versatility and precision. They can handle a wide variety of fabrics, from lightweight materials like cotton and silk to heavier textiles such as denim and canvas. The single needle configuration allows for a straight stitch, which is the most commonly used stitch in garment assembly. This simplicity translates to ease of use for operators, enabling sharp and clean stitching that is vital for high-quality production.

One of the most significant advantages of the single needle lock stitch technology lies in its consistency. Each stitch is formed by a single needle and a bobbin thread, which ensures a tight, secure seam. This reliability is essential for manufacturers aiming to produce durable garments that can withstand the rigors of everyday wear. Moreover, the precise nature of the lock stitch means reduced likelihood of fabric puckering, an issue that can often plague multi-needle machines.

industrial single needle lock stitch sewing machine with needle guard

Safety is a critical concern in industrial sewing environments, and the inclusion of a needle guard in these machines addresses this issue directly. The needle guard serves as a protective barrier that minimizes the risk of accidents during operation. It prevents the operator from coming into direct contact with the moving needle, thereby protecting against potential injuries. This feature promotes a safer working environment, allowing operators to focus on their tasks with greater peace of mind.

Furthermore, the industrial single needle lock stitch sewing machine with a needle guard is equipped with advanced features that enhance its functionality. Many models include adjustable stitch length settings, allowing for customization depending on the fabric and the specific requirements of the project. Machines may also come with automatic thread trimmers, which streamline the sewing process by eliminating the need for manual cutting and reducing waste.

Maintenance of these machines is relatively straightforward, making them ideal for industrial settings where downtime must be minimized. Regular oiling and timely replacement of needles ensure that the sewing machine operates at peak performance, prolonging its lifespan and maintaining stitch quality.

In conclusion, the industrial single needle lock stitch sewing machine with a needle guard is an invaluable asset in the textile industry. Its combination of efficiency, precision, and safety makes it a preferred choice for garment manufacturers across the globe. As the demand for quality textiles continues to grow, investing in such advanced sewing machinery will undoubtedly yield fruitful results, ensuring that manufacturers can meet consumer needs while maintaining a safe and productive work environment. This machine is not just a tool; it is a partner in the quest for excellence in fashion manufacturing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025