industrial sewing machine single needle

The Industrial Sewing Machine A Focus on Single Needle Models

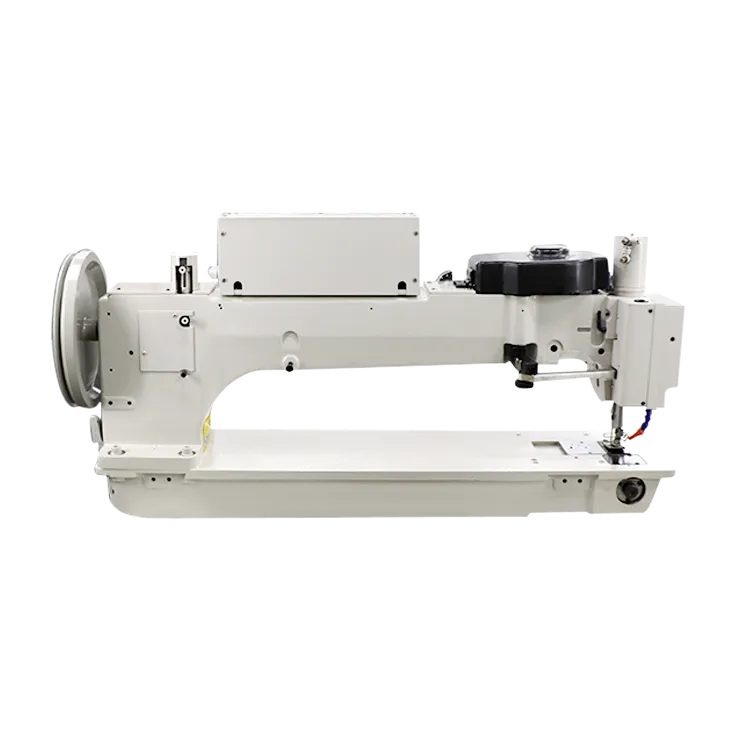

Industrial sewing machines play a crucial role in the textile and garment manufacturing industry, facilitating the production of high-quality garments at an impressive speed. Among the various types of industrial sewing machines, the single needle sewing machine stands out due to its versatility, efficiency, and the quality of seams it produces. This article delves into the features, advantages, and applications of single needle industrial sewing machines.

Features of Single Needle Sewing Machines

Single needle sewing machines are designed to use a single needle to stitch fabric together, and they are synonymous with precision. Typically, these machines are equipped with a robust motor to handle heavy-duty fabrics, allowing for the stitching of multiple layers with ease. A prominent feature of single needle machines is their ability to perform a wide range of stitch types, including straight, zigzag, and decorative stitches, making them suitable for various applications in the garment industry.

Furthermore, many models incorporate advanced technology, such as automatic thread tension control and programmable sewing patterns, enhancing user efficiency and reducing the chances of errors. The machines are often designed with heavy-duty metal frames, which ensure stability during operation, leading to consistent and reliable output.

Advantages of Using Single Needle Machines

One of the main advantages of single needle sewing machines is their simplicity. With fewer moving parts compared to multi-needle models, they are generally easier to operate and maintain. This simplicity makes them an ideal choice for both seasoned professionals and beginners alike.

industrial sewing machine single needle

Another benefit is their versatility. Single needle machines can handle various fabric types, from lightweight materials like silk to heavier textiles like denim and canvas. This adaptability is crucial in the fashion industry, where different projects often require different fabric types and techniques.

Moreover, single needle sewing machines produce high-quality seams. The precision offered by a single needle ensures that the stitches are uniform, which is vital for creating professional-looking garments. The ability to adjust stitch length and tension allows operators to modify settings according to specific project requirements, further enhancing the quality of the final product.

Applications in the Garment Industry

Single needle sewing machines have a wide range of applications in the garment manufacturing sector. They are particularly valued in the production of tailored garments, where accuracy and attention to detail are paramount. Fashion designers and manufacturers often rely on these machines for constructing blouses, shirts, and other apparel that require fine finishing.

In addition to clothing production, single needle machines are commonly used in the production of accessories such as bags, belts, and hats. Their ability to handle intricate designs and layering makes them suitable for any task that demands precision stitching.

Conclusion

In conclusion, the industrial single needle sewing machine is an indispensable tool in the garment manufacturing industry. Its combination of simplicity, versatility, and precision stitching capabilities make it a favorite among manufacturers. As the fashion industry continues to evolve, the demand for high-quality, efficiently produced garments will ensure that single needle machines remain at the forefront of industrial sewing technology. Whether for mass production or detailed custom work, the single needle sewing machine stands as a testament to the artistry and efficiency of modern textile manufacturing.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025