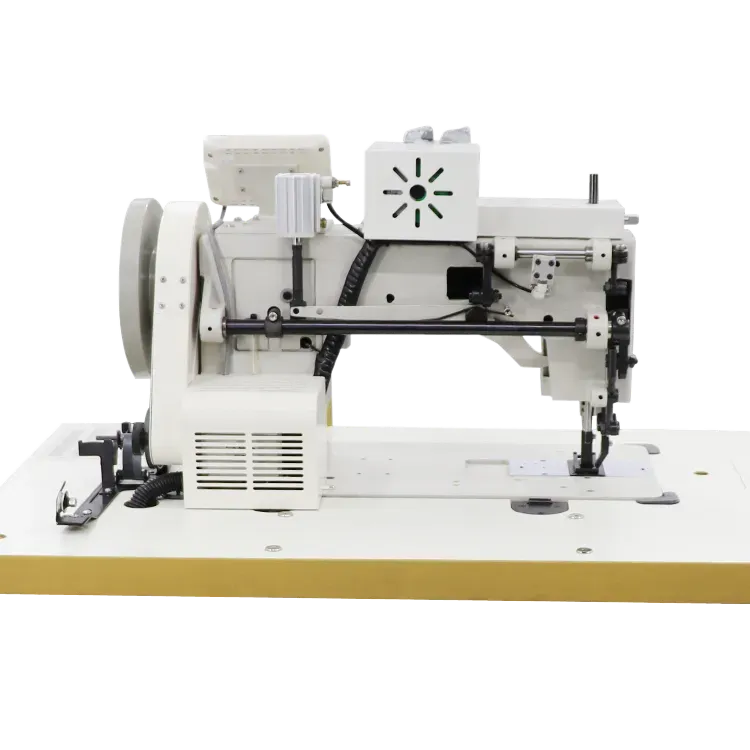

industrial leather machine

The Role of Industrial Leather Machines in Modern Leather Production

In the contemporary world, the leather industry plays a pivotal role in fashion, automotive, and various other sectors. The intricate process of transforming raw hides into finished leather goods necessitates the use of specialized machinery. Industrial leather machines have revolutionized this industry, enhancing efficiency, quality, and sustainability.

Industrial leather machines encompass a wide range of equipment designed for different stages of leather production, including tanning, drying, finishing, and cutting. Each machine is engineered to perform specific tasks that contribute to the overall quality of the leather. For instance, during the tanning process, chemicals are used to preserve the raw hides, and industrial tanning machines ensure that this process is executed uniformly, preventing any defects in the final product. This precision is vital, as the quality of the leather greatly influences its durability and appearance.

One of the most significant advancements in industrial leather machinery is the automation of processes. Automated machines are capable of handling large volumes of leather quickly and consistently. This has not only reduced the time taken to produce leather goods but also minimized human error. Automation allows for greater precision in tasks like cutting and embossing, which are critical for creating high-quality leather products that meet consumer demands.

industrial leather machine

Sustainability has become increasingly important in the leather industry, with consumers becoming more conscious of ethical manufacturing practices. Modern industrial leather machines are now designed with an emphasis on sustainability. Innovative technologies, such as water recycling systems and energy-efficient operations, help to reduce the environmental impact of leather production. Some machines even utilize vegetable tanning processes, which are less harmful to the environment compared to traditional chemical methods. This shift not only benefits the planet but also appeals to a market that prioritizes eco-friendly products.

Additionally, the introduction of computer numerical control (CNC) technology in leather cutting machines has enhanced design possibilities. CNC machines allow for intricate patterns and designs to be cut with unparalleled precision, opening up creative avenues for designers. This technological integration means that luxury brands can offer unique products while maintaining strict quality control.

Moreover, maintenance-free features and user-friendly interfaces in modern machines have made them more accessible to manufacturers. Training workers to operate these machines is straightforward, which increases productivity and reduces downtime. As the leather industry continues to evolve, companies investing in state-of-the-art industrial leather machinery are finding themselves at a competitive advantage.

In conclusion, industrial leather machines are indispensable to the modern leather industry. They facilitate efficient production processes, enhance product quality, and promote sustainable practices. As technology advances, these machines will likely become even more sophisticated, further transforming the landscape of leather production. The combination of innovation and sustainability is essential for meeting the challenges of the future while satisfying the demands of an ever-evolving market. By embracing these advancements, the leather industry can continue to thrive and maintain its relevance in a dynamic global environment.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025