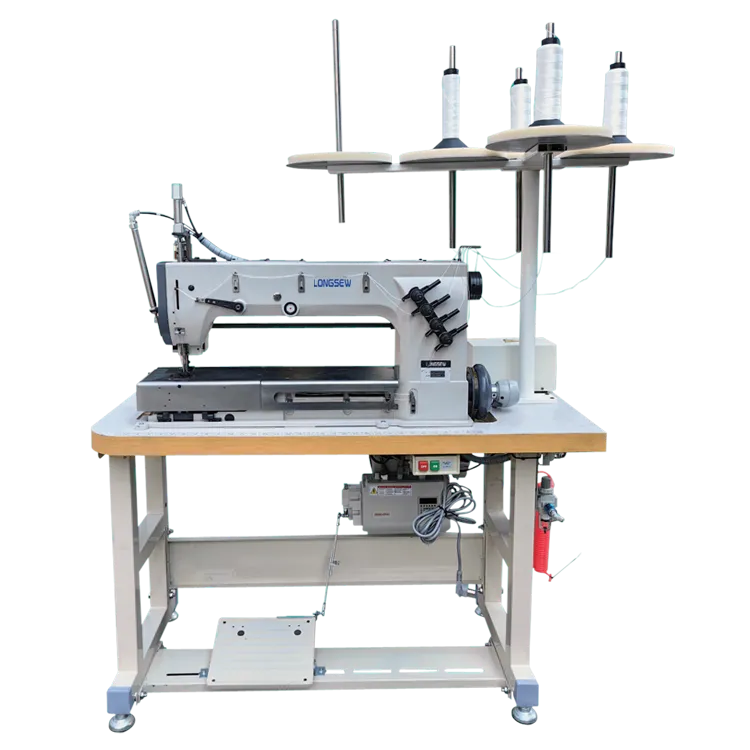

heavy industrial sewing machine

The Evolution and Significance of Heavy Industrial Sewing Machines

In the realm of textile production, heavy industrial sewing machines play a pivotal role in transforming raw materials into finished products. These machines are designed to handle thick and heavy fabrics, making them indispensable for various industries, including apparel manufacturing, upholstery, leather goods, and automotive sectors. The evolution of heavy industrial sewing machines marks a significant advancement in sewing technology, contributing to increased efficiency, consistency, and quality in textile production.

Heavy industrial sewing machines differ from their lighter counterparts in terms of power, durability, and functionality. Equipped with robust motors and advanced stitching mechanisms, these machines can effortlessly sew through multiple layers of tough materials, such as denim, canvas, and synthetic fabrics. The heavy-duty design ensures longevity, enabling companies to invest in machines that withstand the rigors of high-volume production environments.

One of the key features that distinguish heavy industrial sewing machines is their versatility. Manufacturers offer a wide range of models, each designed for specific applications. For instance, walking foot sewing machines are popular for quilting and leatherwork, as they provide better feed control for uneven materials. Similarly, chain stitch machines are favored for serging operations, allowing for faster assembly lines. This versatility enables manufacturers to choose the right machine tailored to their production needs, resulting in optimized workflows and reduced operational costs.

heavy industrial sewing machine

The introduction of computerized heavy industrial sewing machines has further revolutionized the industry. Modern models often come equipped with programmable features, allowing operators to store patterns, adjust stitch lengths, and control tension settings with great precision. This level of automation not only enhances productivity but also minimizes human error, ensuring consistent quality across large production runs.

Moreover, heavy industrial sewing machines contribute significantly to economic growth within the garment sector. By enhancing production capabilities, they enable companies to meet the growing demands of global markets. This increased efficiency often translates to competitive pricing, benefitting both manufacturers and consumers. Furthermore, as the fashion industry evolves with trends such as fast fashion, the need for rapid prototyping and production has never been greater, making heavy industrial sewing machines an essential investment for businesses aiming for competitive advantage.

In conclusion, heavy industrial sewing machines are at the forefront of textile manufacturing, playing an essential role in the production of various goods ranging from clothing to automotive interiors. Their robust design, versatility, and technological advancements have paved the way for increased efficiency and quality in the industry. As the demand for high-quality, durable products continues to rise, heavy industrial sewing machines will remain a critical component in meeting the challenges of modern textile production. With ongoing innovations in design and functionality, these machines will undoubtedly shape the future of the textile industry, ensuring it remains a vital part of the global economy.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025