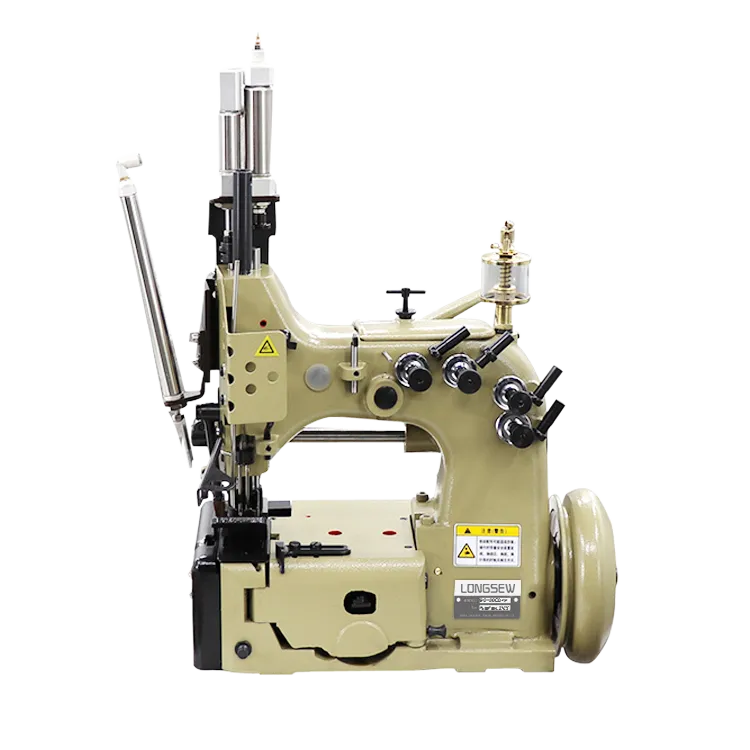

fibc bag lockstitch

The Importance of Lockstitch in FIBC Bag Production

Flexible Intermediate Bulk Containers (FIBCs), commonly known as bulk bags or Jumbo bags, have revolutionized the way bulk materials are transported and stored in various industries. When it comes to the production of these durable containers, the type of stitching used plays a crucial role in determining the bag's strength and reliability. Among the various stitching methods available, lockstitch is widely regarded as one of the most effective and popular techniques for FIBC construction.

The Importance of Lockstitch in FIBC Bag Production

Moreover, lockstitch seams present a cleaner finish compared to other stitching methods. The interlocking of threads allows for a neat appearance, which not only enhances the aesthetic appeal of the FIBC but also contributes to its structural integrity. A well-finished seam reduces the likelihood of fraying, thus extending the bag's overall lifespan and ensuring that it can endure multiple cycles of use.

fibc bag lockstitch

In addition to its strength and visual appeal, lockstitch is also favored for its versatility. This stitching technique can be adapted for various FIBC designs, including those with additional features such as lifting loops or spouts. Manufacturers can use lockstitching to create customized bags suited to different applications, from agriculture to construction, without compromising on quality.

Another vital aspect of using lockstitch in FIBC production is its cost-effectiveness. The simplicity of the lockstitching process allows for efficient manufacturing, which can significantly reduce labor costs and production time. As a result, manufacturers can deliver high-quality FIBCs at competitive prices, benefitting customers across various industries.

Sustainability is becoming increasingly important in modern manufacturing, and the lockstitch method aligns well with this trend. The longevity provided by lockstitch seams reduces the frequency of bag replacements, contributing to lower waste and a more sustainable approach to bulk packaging. By investing in quality FIBCs with lockstitch seams, companies can enhance their sustainability efforts while still meeting their operational needs.

In conclusion, the significance of lockstitch in FIBC bag production cannot be overstated. Its strength, clean finish, versatility, cost-effectiveness, and sustainability make it an ideal choice for manufacturing bulk bags. As industries continue to evolve and seek reliable and efficient packaging solutions, the lockstitch method will undoubtedly remain a cornerstone in the production of durable FIBC bags, ensuring that businesses can safely transport and store their materials with confidence.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025