Automated Sewing Solutions for FIBC Bag Production and Efficiency Enhancement

Advancements in FIBC Bag Production The Role of Computerized Sewing Machines

In the realm of industrial packaging, FIBC (Flexible Intermediate Bulk Container) bags have emerged as a vital solution for transporting bulk materials. These sturdy bags, capable of holding up to several tons of material, are widely used in various industries, including agriculture, chemicals, and construction. The increasing demand for FIBC bags has led manufacturers to explore efficient production methods, with computerized sewing machines at the forefront of this transformation.

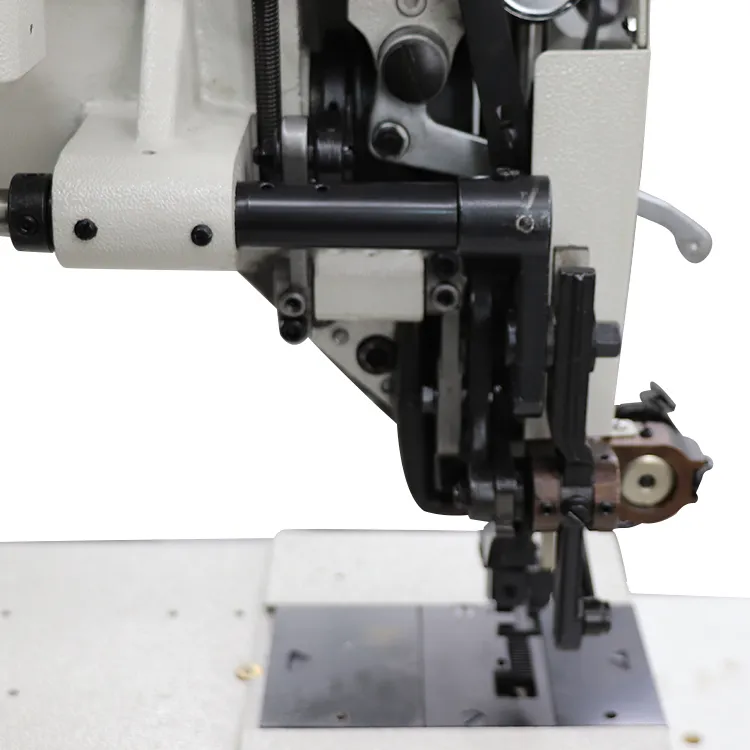

Computerized sewing machines have revolutionized the way FIBC bags are produced. Traditionally, the sewing of these bags required skilled labor and manual manipulation, which could result in inconsistencies and longer production times. The integration of computerized technology into the sewing process has improved accuracy, speed, and overall product quality. These advanced machines are equipped with software that allows for precise design specifications, enabling manufacturers to create bags that meet specific requirements for size, shape, and durability.

Advancements in FIBC Bag Production The Role of Computerized Sewing Machines

Furthermore, the speed at which these machines operate is a substantial benefit. Automated sewing processes can dramatically decrease production times, allowing manufacturers to meet high-demand orders without sacrificing quality. Where manual sewing would take hours, computerized machines can complete tasks in a fraction of the time, thus boosting overall productivity. This efficiency is especially crucial in today’s fast-paced market, where timely delivery is often a key differentiator among competitors.

fibc bag computerized sewing machine

Additionally, computerized sewing machines are designed with user-friendly interfaces, making them accessible to operators with varying levels of expertise. Training staff to use these machines can be accomplished quickly, ensuring that companies can maintain high output levels with a relatively short learning curve. This aspect further amplifies the return on investment for manufacturers looking to upgrade their production lines.

The durability and reliability of FIBC bags are paramount, particularly in industries like chemicals and food processing, where safety and compliance are non-negotiable. Computerized sewing machines contribute significantly to achieving these standards. They ensure that stitching is not only strong but also consistent across entire production runs. With fewer defects resulting from automated processes, companies can reduce waste and lower costs associated with quality control.

Moreover, as sustainability becomes a growing concern across industries, the efficiency provided by computerized sewing machines can also lead to greener production practices. By optimizing material usage and minimizing waste during the manufacturing process, companies can contribute to environmental conservation efforts while maintaining profitability.

In conclusion, the integration of computerized sewing machines into the production of FIBC bags marks a significant evolution in manufacturing practices. These machines enhance efficiency, improve product quality, and reduce production times, ultimately empowering manufacturers to meet the increasing demand for reliable bulk packaging solutions. As technology continues to advance, EIBC bag manufacturers who embrace these innovations will not only enhance their operational capabilities but also secure a competitive edge in the marketplace. The future of FIBC bag production looks bright, driven by the efficiencies and precision that computerized sewing machines bring to the table.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025