Automated Sewing Solutions for FIBC Bags with Advanced Computer Technology

Revolutionizing FIBC Production with Computerized Sewing Machines

In the landscape of industrial textile manufacturing, FIBC (Flexible Intermediate Bulk Container) bags have emerged as a vital solution for bulk material handling. These versatile and durable bags are widely used in various industries, from agriculture to chemicals and construction. The evolution of FIBC production has been significantly enhanced by the advent of computerized sewing machines, which have transformed traditional sewing practices into a streamlined, efficient, and highly accurate process.

Understanding FIBC Bags

Before delving into the impact of computerized sewing machines, it’s essential to comprehend what FIBC bags are and their significance in the market. These bags, often referred to as bulk bags, are designed to hold large quantities of dry products ranging from grains and powders to granules and small parts. They are made from woven polypropylene fabric, which grants them strength and durability while maintaining a lightweight profile. The primary advantages of using FIBC bags include their reusability, cost-effectiveness, and environmental sustainability, making them a preferred choice for many businesses.

The Role of Computerized Sewing Machines

The sewing process is critical in the manufacturing of FIBC bags, as it ensures that the seams are strong enough to withstand heavy loads. Traditional sewing methods, while effective, often fall short in terms of precision and consistency, leading to potential failures under stress. This is where computerized sewing machines come into play.

Computerized sewing machines utilize advanced technology to automate the sewing process, which results in numerous benefits

1. Increased Precision Computerized sewing machines deliver high levels of precision in stitching, as they are programmed to follow specific patterns and measurements. This accuracy is crucial in FIBC production, where even the slightest deviation can compromise the bag's integrity.

2. Consistency in Quality With automated processes, every bag produced can meet the same quality standards. This consistency reduces the risk of defects and ensures that each FIBC bag meets regulatory requirements for strength and safety.

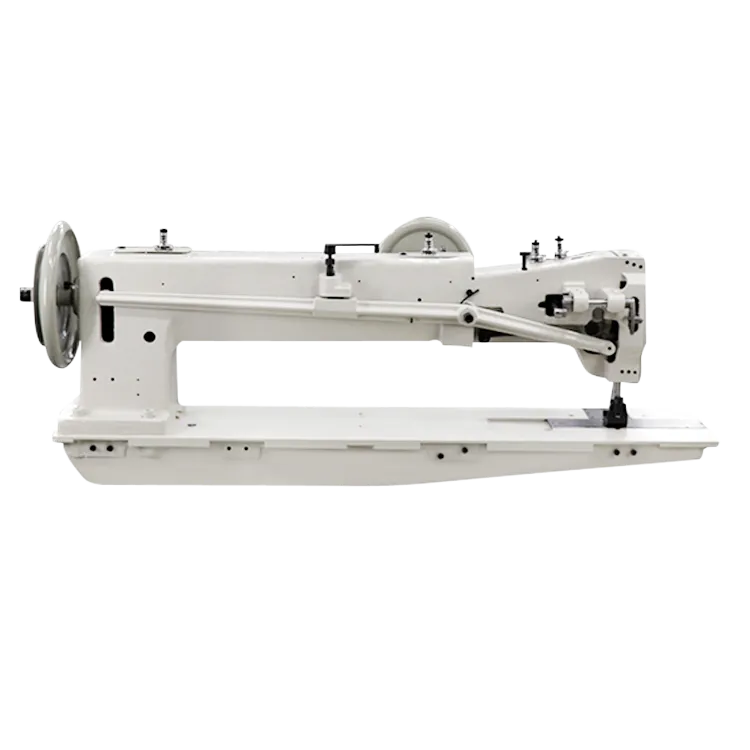

fibc bag computerized sewing machine

3. Enhanced Productivity These machines can operate at high speeds, significantly increasing production rates compared to manual sewing. As a result, manufacturers can meet the growing demand for FIBC bags without sacrificing quality or increasing labor costs.

4. Versatility in Design Computerized sewing machines can easily switch between different bag designs and sizes, offering manufacturers flexibility. This adaptability is essential for meeting the diverse needs of various industries applying custom specifications for bag dimensions and sewing styles.

5. Reduced Material Waste The accuracy and automated nature of computerized sewing minimize material waste. Manufacturers can efficiently use the fabric to produce more FIBC bags per roll, thereby lowering production costs and reducing environmental impact.

The Future of FIBC Production

The integration of computerized sewing technologies is paving the way for the future of FIBC bag manufacturing. As industries continue to expand and evolve, the demands for innovative packaging solutions will grow. Computerized sewing machines will undoubtedly play a crucial role in meeting these demands, offering manufacturers the tools to produce high-quality, reliable products swiftly.

Moreover, as sustainability becomes an increasingly pressing issue, manufacturers equipped with advanced sewing technology can adopt more environmentally-friendly practices. Enhanced efficiency leads to reduced energy consumption and less material waste, aligning production processes with global efforts toward sustainability.

Conclusion

The impact of computerized sewing machines on FIBC bag production is profound. By enhancing precision, consistency, and productivity, these machines not only improve the manufacturing process but also provide solutions that align with modern market demands. As the FIBC industry continues to grow, adapting to new technologies will be essential for manufacturers looking to maintain competitive advantages while contributing to a more sustainable future. The combination of advanced sewing technology and innovative design will ensure that FIBC bags remain a vital component of bulk material handling for years to come.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025