Understanding the Functionality of Double Needle Chain Stitch Machines for Sewing Applications

Understanding the Double Needle Chain Stitch Machine

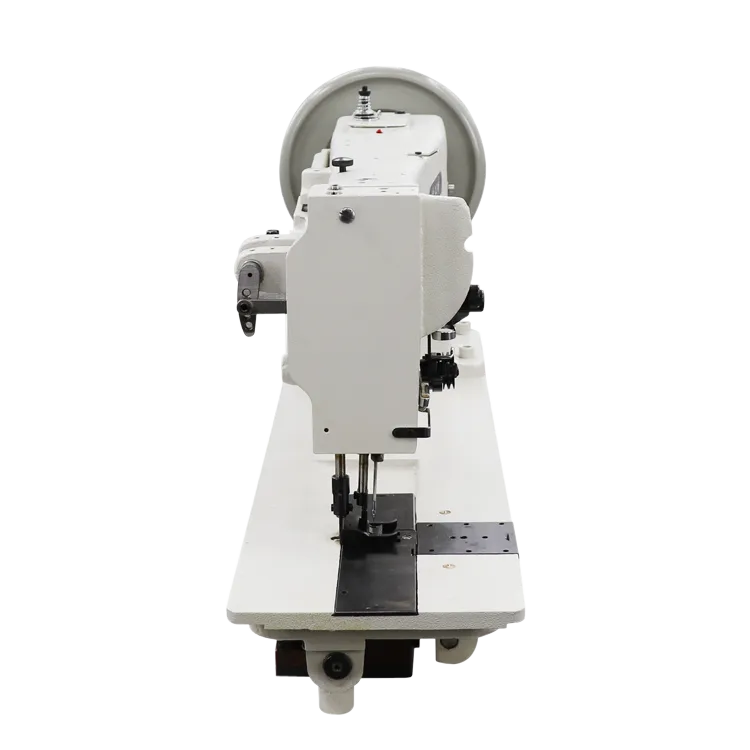

The double needle chain stitch machine is a specialized piece of equipment widely used in the textile and garment industry. Renowned for its versatility and efficiency, this machine utilizes two needles to create a robust stitch that combines the characteristics of both a chain stitch and traditional lockstitch, making it ideal for various sewing applications.

One of the primary advantages of the double needle chain stitch machine is its ability to produce a seamless finish and durable seams. The chain stitch is created by looping the thread back onto itself, which provides a certain amount of elasticity—an essential feature for garments that require flexibility, such as activewear or stretch fabrics. This elasticity helps prevent the seams from ripping and enhances the overall durability of the finished product.

The operation of a double needle chain stitch machine is relatively straightforward. It involves threading two needles that penetrate the fabric simultaneously while a looper mechanism secures the thread in place. This design allows for the creation of two parallel rows of stitching, which can be particularly advantageous for decorative purposes or for adding reinforcement to areas prone to stress, such as armholes or inseams.

Another significant benefit of this machine is its efficiency in production. The ability to sew two lines of stitches at once not only speeds up the manufacturing process but also conserves thread, which translates to cost savings for manufacturers. This efficiency is particularly beneficial in high-volume production settings where time and resources are precious.

double needle chain stitch machine

In addition to its functional strengths, the double needle chain stitch machine also offers aesthetic appeal. The pattern created by the dual stitching can enhance the visual aspect of a garment, providing a tailored and professional finish. Fashion designers often employ this machine to achieve unique styles, such as the 'flatlock' seam, which is commonly used in sportswear to create a smooth and comfortable fit against the skin.

Despite its many advantages, operating a double needle chain stitch machine does require some skill and experience. Adjusting tension for the different threads can be tricky, and incorrect tension can lead to puckering or uneven stitches. Furthermore, because of the complexity of the machine, industries often invest in training for their workers to ensure optimal operation and minimal waste.

Maintenance of the double needle chain stitch machine is also critical for its longevity and performance. Regular cleaning, oiling, and timely servicing can prevent breakdowns and ensure that the machine runs smoothly. By adhering to a rigorous maintenance schedule, manufacturers can avoid production delays and enhance their operational efficiency.

In conclusion, the double needle chain stitch machine is a valuable asset in the textile industry, offering advantages that range from durability to aesthetic flexibility. Its ability to handle multiple lines of stitching efficiently makes it a preferred choice for manufacturers aiming to produce high-quality, resilient garments. As fashion trends evolve and demand for innovative designs increases, the double needle chain stitch machine will undoubtedly remain a crucial player in the world of sewing.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025