Feb . 15, 2025 17:16

Back to list

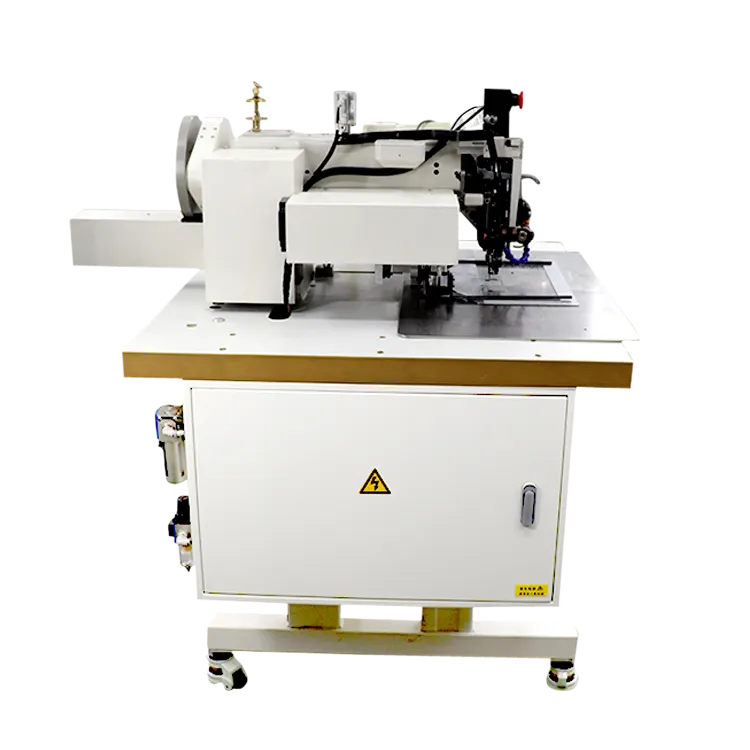

Extra Heavy Duty Top & Bottom Feeding Flat Bed Sewing Machine GA733/GA733-L30

The bobbin case shuttle hook is an essential component of sewing machines, a crucial element that ensures the smooth operation and high-quality stitching required in both domestic and industrial sewing applications. Understanding its functionality, importance, and maintenance can significantly enhance your sewing experience. This article delves into the bobbin case shuttle hook, providing insights from experts and experienced users while emphasizing its significance in the sewing ecosystem.

Manufacturers and suppliers play a critical role in the continual development of bobbin case shuttle hook technology. Leading companies invest heavily in research and development to introduce innovations that further enhance efficiency and output quality. Recent advances include the integration of low-friction coatings and improved geometry designs that reduce thread breakage and increase threading speed. Consultation with suppliers can provide insights into the latest models and performance features available, aiding in making informed purchasing decisions for upgraded machinery or components. The credibility of information regarding bobbin case shuttle hooks can be validated by consulting authoritative sources such as sewing machine manuals, technical websites, and industry forums. Blogs written by sewing machine engineers and seasoned artisans also offer reliable advice and troubleshooting tips. Building a network with other professionals through online communities or local sewing clubs can provide invaluable peer support and knowledge exchange, reinforcing trust in shared informational resources. For novices venturing into the world of sewing, understanding the complexities of a bobbin case shuttle hook can seem daunting. However, heeding advice from experts and learning through experience builds confidence in effectively managing this crucial sewing machine component. Keeping abreast of technological advancements and maintaining a proactive maintenance routine contributes significantly to a fulfilling and productive sewing journey. Incorporating the expertise of machinists, instructors, and experienced users, this comprehensive guide on bobbin case shuttle hooks serves as a definitive resource for all sewing enthusiasts. It combines technical know-how with practical advice, thereby establishing itself as a trustworthy and authoritative reference in the sewing industry.

Manufacturers and suppliers play a critical role in the continual development of bobbin case shuttle hook technology. Leading companies invest heavily in research and development to introduce innovations that further enhance efficiency and output quality. Recent advances include the integration of low-friction coatings and improved geometry designs that reduce thread breakage and increase threading speed. Consultation with suppliers can provide insights into the latest models and performance features available, aiding in making informed purchasing decisions for upgraded machinery or components. The credibility of information regarding bobbin case shuttle hooks can be validated by consulting authoritative sources such as sewing machine manuals, technical websites, and industry forums. Blogs written by sewing machine engineers and seasoned artisans also offer reliable advice and troubleshooting tips. Building a network with other professionals through online communities or local sewing clubs can provide invaluable peer support and knowledge exchange, reinforcing trust in shared informational resources. For novices venturing into the world of sewing, understanding the complexities of a bobbin case shuttle hook can seem daunting. However, heeding advice from experts and learning through experience builds confidence in effectively managing this crucial sewing machine component. Keeping abreast of technological advancements and maintaining a proactive maintenance routine contributes significantly to a fulfilling and productive sewing journey. Incorporating the expertise of machinists, instructors, and experienced users, this comprehensive guide on bobbin case shuttle hooks serves as a definitive resource for all sewing enthusiasts. It combines technical know-how with practical advice, thereby establishing itself as a trustworthy and authoritative reference in the sewing industry.

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025