Advanced Back Closer Technology for Enhanced Manufacturing Efficiency and Precision

The Back Closer Machine Revolutionizing the Packaging Industry

In today's fast-paced manufacturing landscape, efficiency and precision are paramount. Among the numerous innovations that have emerged to enhance operational workflows, the Back Closer Machine stands out as a transformative tool in the packaging industry. This specialized machinery is designed to automate and streamline the process of sealing and closing bags, pouches, and other forms of packaging. In this article, we will explore the features, benefits, and impact of the Back Closer Machine on modern manufacturing.

What is a Back Closer Machine?

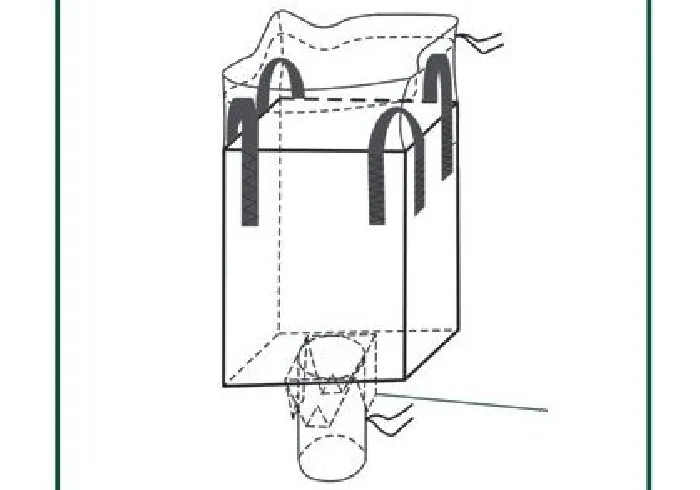

A Back Closer Machine is an automated device used primarily in the packaging sector to seal the open end of flexible packaging materials like bags or pouches. It typically works in conjunction with a filling machine, where products are placed inside the packaging before being sealed. The Back Closer Machine ensures that the packaging is securely closed, providing an airtight seal that helps preserve the quality and freshness of the contents.

These machines come in various configurations to accommodate different types of packaging materials, including plastic, paper, and foil. They can be designed to operate with different sealing methods, such as heat sealing, cold sealing, or adhesive sealing, depending on the requirements of the products being packaged.

Key Features

1. Automation One of the significant advantages of the Back Closer Machine is its automation capabilities. With advanced sensors and control systems, these machines can operate with minimal human intervention, significantly increasing production speed and reducing the risk of errors.

2. Versatility Back Closer Machines are designed to handle a wide range of products and packaging materials. This versatility makes them an attractive option for companies with diverse product lines, allowing for quick adjustments between different packaging specifications.

3. Integration These machines can easily integrate with existing production lines, working seamlessly alongside fillers, conveyors, and other automated machinery. This integration not only enhances workflow efficiency but also allows for real-time monitoring and management of the packaging process.

4. Quality Control Many modern Back Closer Machines are equipped with advanced quality control features, such as automatic inspection systems that detect misaligned packages or weak seals. This ensures that every package leaving the production line meets quality standards.

back closer machine

5. User-Friendly Interface The latest models feature intuitive touch screens and user-friendly interfaces, making them accessible to operators of all skill levels. This ease of use reduces training time and helps maintain a smooth production flow.

Benefits of Using a Back Closer Machine

The implementation of a Back Closer Machine can yield significant benefits to manufacturing operations

1. Increased Efficiency By automating the sealing process, companies can greatly increase their output, allowing them to meet growing market demands without compromising on quality.

2. Cost Savings Increased speed and reduced labor costs can lead to significant savings. Additionally, the reduction of waste due to better sealing practices helps to optimize material usage.

3. Enhanced Product Integrity A tightly sealed package helps protect the product from external contaminants, moisture, and spoilage. This is particularly crucial for food and pharmaceutical products.

4. Environmental Impact The precision and efficiency of Back Closer Machines allow for the use of eco-friendly packaging materials without sacrificing quality. Companies can reduce their carbon footprint by minimizing waste and maximizing the use of recyclable materials.

5. Scalability As businesses grow, the scalability of Back Closer Machines can accommodate increased production demands. Manufacturers can easily upgrade or expand their operations without significant overhauls of their packaging lines.

Conclusion

The Back Closer Machine represents a significant advancement in the packaging industry, offering a combination of efficiency, versatility, and quality. As technology continues to evolve, these machines are likely to become even more sophisticated, providing manufacturers with additional tools to optimize their workflows. Embracing such innovations allows companies to stay competitive in an ever-changing market while ensuring that their products are delivered safely and securely to consumers. In a world where packaging plays a crucial role in brand perception and product integrity, the Back Closer Machine is not just a machine—it's a key partner in the journey of manufacturing excellence.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025