Effortless Sewing with an Automatic Button Function Machine for Seamless Projects

The Rise of Automatic Button Sewing Machines Revolutionizing Garment Production

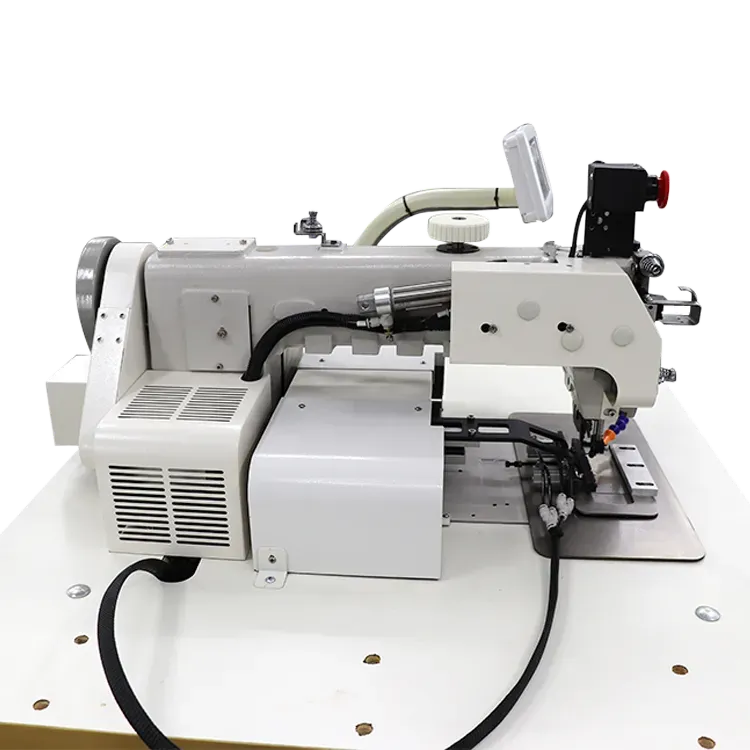

In the ever-evolving landscape of garment manufacturing, technology continues to play a pivotal role in enhancing productivity and precision. Among the innovative machinery that has emerged, the automatic button sewing machine stands out as a game-changer for both large-scale industries and small tailoring businesses. This remarkable device not only simplifies the sewing process but also improves the quality and consistency of button attachment, catering to the demands of modern consumers.

Understanding Automatic Button Sewing Machines

Automatic button sewing machines are specialized sewing machines designed to automate the process of attaching buttons to fabric. Unlike traditional sewing methods that require manual input for each button, these machines streamline the procedure by utilizing advanced technology to regulate the sewing cycle. Operators can set parameters such as button size, stitch type, and location, allowing the machine to execute the task with remarkable speed and precision.

The core components of these machines typically include an automatic button feeder, a sewing unit, and a control panel. The button feeder ensures that buttons are fed into the machine one by one, reducing downtime, while the sewing unit handles the actual stitching process. The control panel allows users to customize settings according to the fabric type and button specifications, making it adaptable for various garments—from shirts to coats.

Benefits of Automatic Button Sewing Machines

1. Increased Efficiency One of the most significant advantages of automatic button sewing machines is their efficiency. These machines can sew multiple buttons in a fraction of the time it would take a skilled seamstress. For manufacturers dealing with high volumes of production, this increase in speed translates into lower labor costs and faster turnaround times.

2. Enhanced Consistency Traditional methods often lead to variations in stitch quality and button placement. Automatic button sewing machines eliminate this inconsistency by providing uniform stitch quality, ensuring that each button is attached securely and looks aesthetically pleasing.

automatic button sewing machine

3. Reduction in Labor By automating the button sewing process, businesses can reduce their reliance on manual labor. This not only decreases labor costs but also allows workers to focus on more complex tasks that require human creativity and skills, such as design and quality control.

4. Versatility Many modern automatic button sewing machines can handle a variety of button styles, sizes, and fabrics, making them a versatile addition to a sewing workshop. This adaptability is crucial in today’s fast-paced fashion industry, where trends and consumer preferences can shift rapidly.

5. Improved Safety Automatic machines are equipped with safety features that reduce the risk of injury associated with manual sewing methods. For instance, sensors can detect blockages or malfunctions, prompting automatic shut-downs to protect both the machine and the operator.

Challenges and Considerations

While automatic button sewing machines offer numerous benefits, there are also challenges to consider. The initial investment cost for these machines can be significant, and small tailoring businesses might struggle to afford them. Additionally, training staff to operate these machines effectively is essential; without proper training, the benefits of automation may not be fully realized.

Moreover, the reliance on technology means that businesses must also be prepared for potential technical failures. Regular maintenance and timely repairs are crucial to ensure that machines function efficiently and do not cause disruptions in the production line.

Conclusion

The automatic button sewing machine represents a significant advancement in sewing technology, paving the way for more efficient, consistent, and safe garment production. As the fashion industry continues to evolve, embracing such innovations will be key to maintaining competitiveness in a saturated market. Whether for large-scale manufacturers or small artisans, investing in automatic button sewing machines can lead to enhanced productivity and ultimately greater customer satisfaction. As businesses weigh the costs and benefits, it is clear that these machines are not just a luxury but a necessity in the modern garment manufacturing landscape.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025