zig zag machine cost

The Cost of Zigzag Machines A Comprehensive Overview

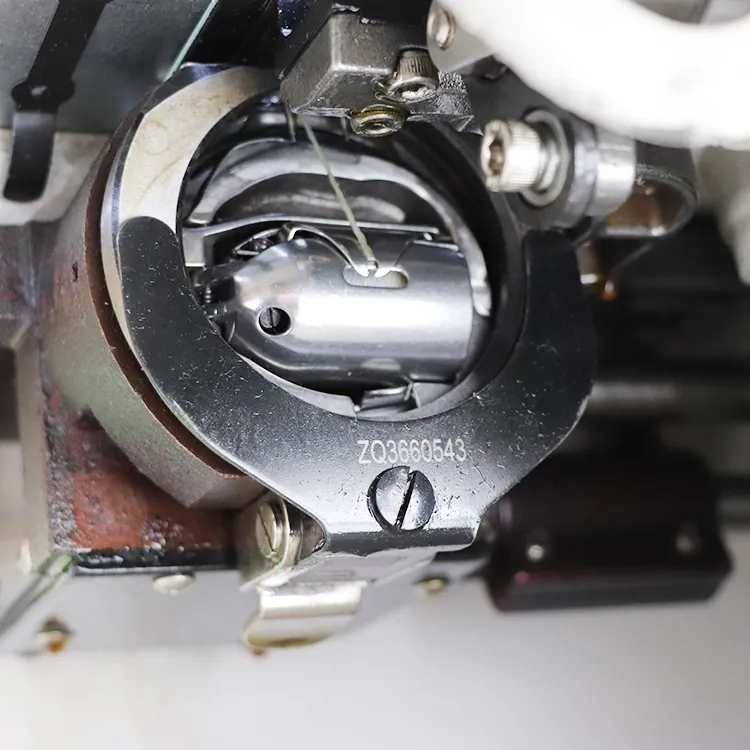

Zigzag machines have become essential tools in various industries, particularly in textiles and garment manufacturing. These machines are designed to create zigzag stitches, which are crucial for both functional and decorative purposes in sewing. As demand for versatile sewing solutions rises, understanding the cost implications of zigzag machines is important for businesses aiming to invest wisely in their production capabilities.

The Cost of Zigzag Machines A Comprehensive Overview

For professionals and businesses, industrial zigzag machines are more appropriate, as they are built for high-volume production and durability. These machines can range from $1,000 to over $10,000. The price is influenced by the machine's speed, the complexity of stitching patterns, automated features, and additional functionalities, such as the ability to handle multiple fabric types. High-end models may also integrate advanced technologies, such as computerized controls, which can significantly enhance efficiency and precision in stitching.

zig zag machine cost

Another crucial factor affecting the cost is the brand reputation. Established brands that offer extensive support services, warranties, and high-quality products typically command higher prices. Investing in a reputable brand may seem more expensive initially, but it can save costs in the long run by reducing maintenance issues and enhancing productivity.

Maintenance and operational costs should also be factored into the overall expenditure on zigzag machines. Regular maintenance is essential to keep the machines running efficiently, which can involve costs for parts replacements, servicing, and occasional upgrades. Additionally, the cost of training staff to operate the machines should be considered, especially for sophisticated models that require specific technical know-how.

Another aspect that influences costs is the local market conditions and import duties. For businesses operating in regions where these machines are imported, tariffs can add a significant markup to the base price. Therefore, conducting thorough market research and exploring local suppliers can sometimes yield more affordable options.

In conclusion, while the initial investment in a zigzag machine can vary widely, understanding the diverse factors contributing to this cost is critical for making informed purchasing decisions. By weighing the upfront cost against potential long-term benefits, businesses can select the right zigzag machine that meets their production needs without straining their budget. Careful planning and consideration will ultimately lead to enhanced productivity and quality in sewing projects, resulting in better overall profitability.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025