Exploring the Advantages of Twin Needle Industrial Sewing Machines for Enhanced Stitching Versatility

The Twin Needle Industrial Sewing Machine A Game Changer in Textile Manufacturing

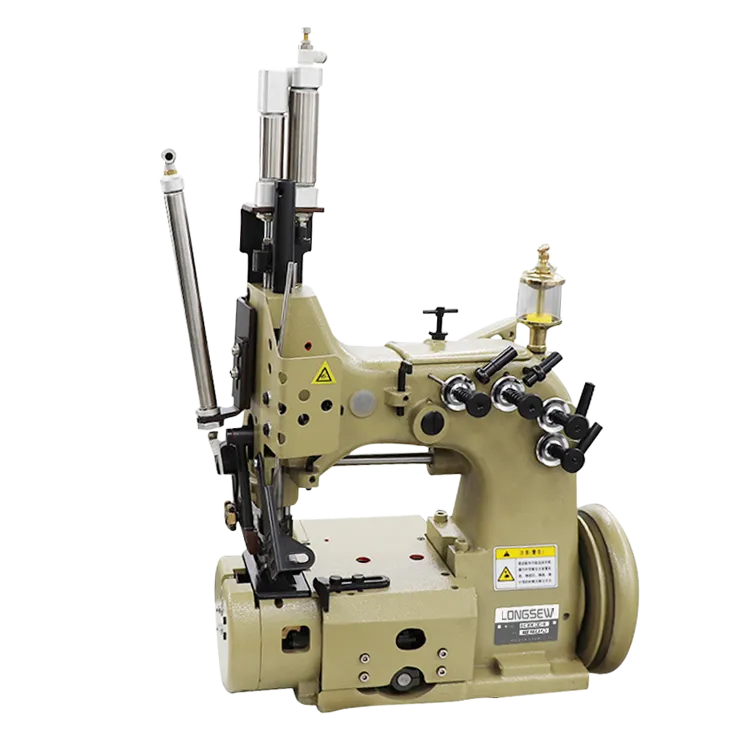

In the ever-evolving world of textile manufacturing, the twin needle industrial sewing machine stands out as a remarkable innovation that has transformed the way fabrics are stitched together. This specialized equipment is designed to create parallel stitching lines on fabrics, allowing for enhanced durability and aesthetic appeal. Let’s delve into the features, advantages, and applications of twin needle industrial sewing machines and explore why they have become indispensable tools in the garment industry.

Features of Twin Needle Industrial Sewing Machines

A twin needle industrial sewing machine operates using two needles that share a single thread cone. This unique setup enables the machine to sew two lines of stitches simultaneously. A critical component of the machine is its designated presser feet, which can accommodate various fabric types and thicknesses, ensuring versatile application across different textile projects. The machine is equipped with a tension control system, allowing users to achieve the perfect stitch tension for different materials.

In addition, many twin needle industrial machines come with advanced features such as programmable stitch patterns, automatic thread cutting, and built-in walking feet. These features not only enhance the efficiency of sewing operations but also improve the overall quality of the finished product. The capability to adjust the distance between the two needle lines adds another layer of customization, making it suitable for various design requirements.

Advantages of Using Twin Needle Machines

One of the primary advantages of twin needle industrial sewing machines is their ability to produce decorative and functional stitches in one pass

. This saves time and labor costs, making them a cost-effective solution for manufacturers. The parallel stitches are not only visually appealing but also significantly enhance the strength of seams, which is particularly important for garments subjected to stress, such as activewear and denim apparel.twin needle industrial sewing machine

Moreover, using a twin needle machine allows for greater creativity in design. Seamstresses can incorporate different stitch types and patterns, adding unique elements to their creations. This versatility makes the twin needle machine a favorite among fashion designers and manufacturers looking to differentiate their products in a competitive market.

The twin needle also plays a crucial role in the realm of stretch fabrics. When sewn with a straight stitch, stretchy materials may pucker or lose their elasticity. The twin needle creates a zigzag stitch on the reverse side, which allows for the fabric to maintain its stretch without compromising seam integrity. This feature is particularly valuable in the production of clothing items such as leggings, swimwear, and sportswear.

Applications in the Textile Industry

The applications of twin needle industrial sewing machines are extensive. They are widely used in the production of various textile products, ranging from home furnishings to apparel. In the fashion industry, these machines are popular for sewing hems, necklines, and decorative seams on garments. In addition, they play a vital role in creating high-quality finishes on products such as quilts, sports uniforms, and swimwear.

Furthermore, the automotive industry has also recognized the value of twin needle sewing machines for their ability to produce durable seams on fabrics used in upholstery and interiors. The same goes for the leather goods industry, where intricate stitching is required to ensure both aesthetics and strength.

Conclusion

In summary, the twin needle industrial sewing machine has solidified its place as an essential tool in modern textile manufacturing. Its advanced capabilities not only enhance productivity and efficiency but also elevate the quality of finished products. As the demand for innovative and high-quality textiles continues to grow, the twin needle machine will undoubtedly remain at the forefront of sewing technology, enabling manufacturers to meet the challenges of the ever-changing market with style and precision. Whether it’s high fashion or functional garments, the twin needle machine is a testament to the artistry of sewing in the industrial landscape.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025