PP Woven Bag Stitching Equipment for Efficient Production and Seam Quality

The Importance of PP Woven Bag Stitching Machines in Modern Manufacturing

In the ever-evolving landscape of manufacturing, efficiency and quality are paramount. Among the various tools and machines that facilitate production, the PP woven bag stitching machine has emerged as a crucial component in the packaging industry. These machines play a vital role in the production of polypropylene (PP) woven bags, which are widely used for packaging a variety of products ranging from agricultural produce to industrial materials.

Understanding PP Woven Bags

PP woven bags are made from polypropylene, a durable and lightweight plastic that is highly resistant to moisture and chemicals. These bags are not only cost-effective but also environmentally friendly, especially when produced using recyclable materials. Their robust structure makes them suitable for carrying heavy loads, which is why they are preferred in sectors such as agriculture, construction, and retail. However, the key to maintaining the integrity of these bags lies in the quality of their stitching.

The Role of Stitching Machines

The stitching of PP woven bags is a critical step in the manufacturing process. It ensures that the bags maintain their shape and strength while being filled and transported. The PP woven bag stitching machine automates this process, significantly increasing production speed and reducing labor costs. These machines use high-tensile threads designed to provide maximum strength and durability, ensuring the bags can withstand heavy weights without tearing.

Key Features of PP Woven Bag Stitching Machines

Modern PP woven bag stitching machines come equipped with several advanced features that enhance their efficiency

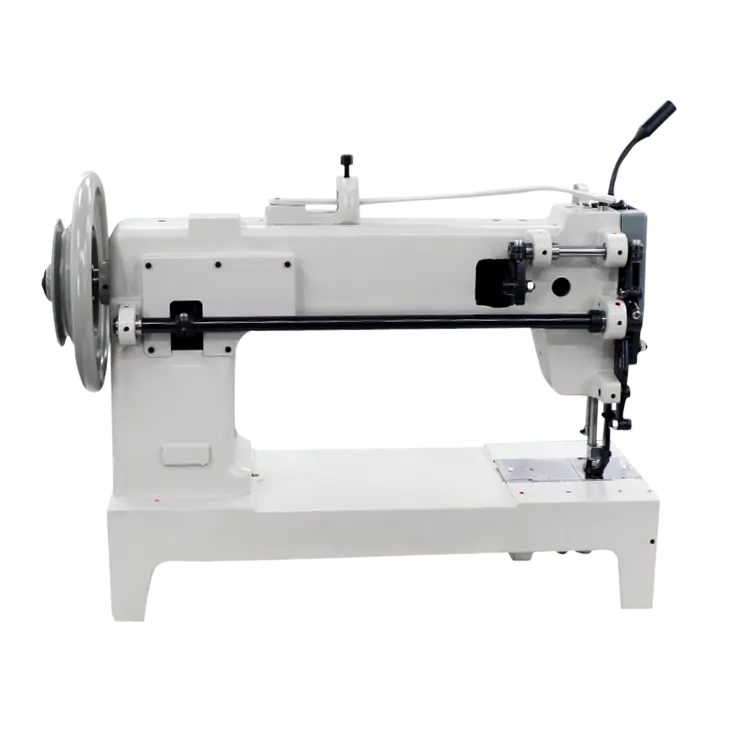

pp woven bag stitching machine

1. Automatic Functionality Many of these machines operate on an automatic scale, allowing for continuous production with minimal human intervention. This results in fewer errors and higher output rates.

2. Adjustable Stitching Options Operators can adjust the stitching patterns and tensions to meet specific requirements of different bag sizes and materials. This versatility makes them suitable for various applications, from small retail bags to large bulk packaging solutions.

3. Precision and Consistency With the help of precise engineering and computerized controls, these machines ensure consistent stitching quality, which is crucial for maintaining the structural integrity of the bags.

4. Durability and Maintenance Most PP woven bag stitching machines are built with durable materials that can withstand the rigors of daily use. Additionally, many models are designed for easy maintenance, reducing downtime and increasing productivity.

The Economic Impact

Investing in a PP woven bag stitching machine can lead to significant economic benefits for manufacturers. By improving production efficiency and reducing labor costs, companies can offer competitive pricing to their customers while maintaining quality. Furthermore, as environmental concerns grow, the adoption of recyclable PP woven bags positions businesses favorably in the market.

Conclusion

The PP woven bag stitching machine is more than just a piece of equipment; it is a vital system that supports the entire packaging industry. As demand for sustainable and reliable packaging solutions continues to grow, these machines will play an increasingly important role in meeting market needs. Manufacturers who invest in advanced stitching technology are not only enhancing their production capabilities but are also contributing to a more sustainable future. With the potential for further innovations, the adoption of these machines is expected to rise, making them indispensable tools in the ongoing evolution of manufacturing practices.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025