Jan . 25, 2025 00:44

Back to list

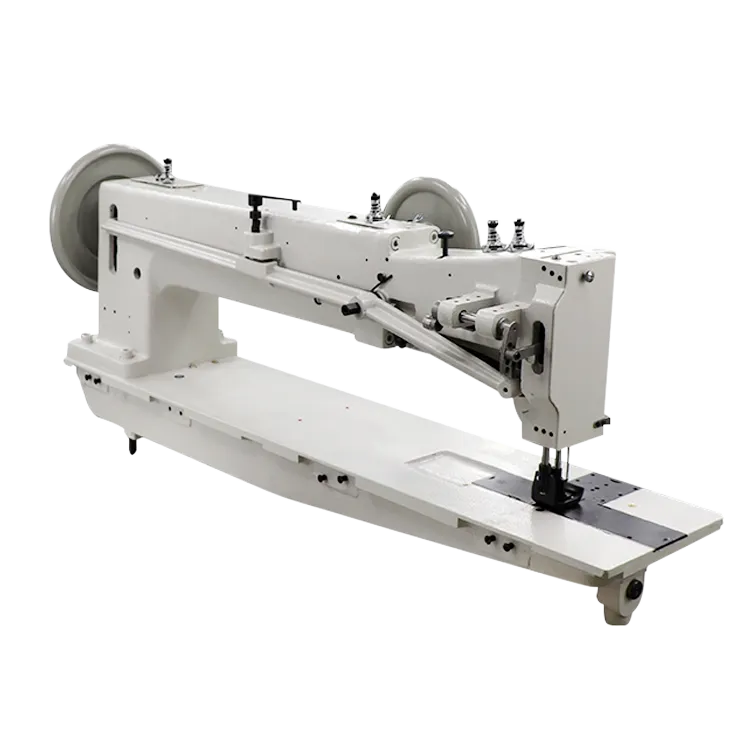

heavy duty needle

Heavy-duty needles have become indispensable tools in various industries, providing unparalleled durability and performance. These specialized needles are specifically designed to handle demanding tasks without breaking or bending. Here, we delve into the realms of usability, professional insight, authoritative comparisons, and trusted advice regarding heavy-duty needles.

Comparative studies of heavy-duty needles underscore their supremacy. Analysis between traditional and heavy-duty variants reveals that the latter substantially reduces frequency of replacements and diminishes the overall operational costs. This efficiency offers firms long-term value, especially in bulk production environments where downtime is not an option. An authoritative perspective comes from manufacturers who stand by their product’s pedigree. Leading brands in heavy-duty needle production conduct rigorous testing, ensuring their needles meet high-performance standards across various applications. This assurance of quality stems from a legacy of innovation and a commitment to excellence, trusting their products to uphold the highest standards of quality control, verified by independent audits and certifications. Trustworthiness in heavy-duty needles is further reinforced by user testimonials. Professionals across disciplines consistently vouch for these tools, often citing reliability and efficiency as major benefits. Such real-world endorsements provide compelling evidence of the needles' performance, fortifying consumer confidence. When a product delivers beyond expectations time and again, it becomes a trusted choice for users who depend on its performance in their everyday tasks. In summary, heavy-duty needles are quintessential for the demands of various professional settings. The unbeatable combination of strength, durability, and precision makes them a revered choice in both medical and industrial applications. Their design, backed by expert engineering and rigorous validation, reassures users of their reliability and effectiveness. For any challenging needlework, investing in heavy-duty needles not only delivers superior performance but also guarantees a level of trust and professional endorsement that is unmatched.

Comparative studies of heavy-duty needles underscore their supremacy. Analysis between traditional and heavy-duty variants reveals that the latter substantially reduces frequency of replacements and diminishes the overall operational costs. This efficiency offers firms long-term value, especially in bulk production environments where downtime is not an option. An authoritative perspective comes from manufacturers who stand by their product’s pedigree. Leading brands in heavy-duty needle production conduct rigorous testing, ensuring their needles meet high-performance standards across various applications. This assurance of quality stems from a legacy of innovation and a commitment to excellence, trusting their products to uphold the highest standards of quality control, verified by independent audits and certifications. Trustworthiness in heavy-duty needles is further reinforced by user testimonials. Professionals across disciplines consistently vouch for these tools, often citing reliability and efficiency as major benefits. Such real-world endorsements provide compelling evidence of the needles' performance, fortifying consumer confidence. When a product delivers beyond expectations time and again, it becomes a trusted choice for users who depend on its performance in their everyday tasks. In summary, heavy-duty needles are quintessential for the demands of various professional settings. The unbeatable combination of strength, durability, and precision makes them a revered choice in both medical and industrial applications. Their design, backed by expert engineering and rigorous validation, reassures users of their reliability and effectiveness. For any challenging needlework, investing in heavy-duty needles not only delivers superior performance but also guarantees a level of trust and professional endorsement that is unmatched.

Previous:

Latest news

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025