gunny bag stitching machine

The Functionality and Importance of Gunny Bag Stitching Machines

In various industries, particularly in agriculture and packaging, gunny bags play a vital role in the transportation and storage of bulk materials. These sturdy sacks, often made from jute or similar materials, are widely used to carry everything from grains to fertilizers. However, the efficiency and reliability of gunny bags depend significantly on the stitching process, which is where gunny bag stitching machines come into play.

Understanding Gunny Bag Stitching Machines

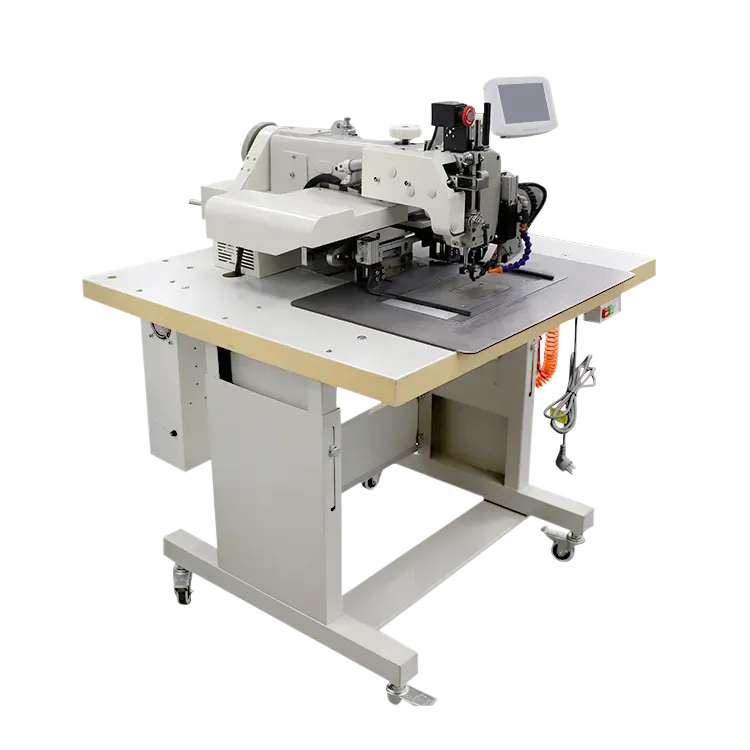

Gunny bag stitching machines are specialized industrial machines designed to sew together the edges of gunny bags securely. These machines enhance productivity by automating the stitching process, ensuring that bags are tightly sealed to prevent spillage of contents during transport and storage. The stitching process is crucial not only for the efficiency of packing but also for maintaining the quality and safety of the materials being contained.

These machines are highly engineered to handle the unique requirements of gunny bags. They are capable of using various stitching techniques, including single-thread stitching and double-thread stitching, depending on the strength needed for the bag. The stitches themselves must be strong and durable, as gunny bags often carry heavy loads.

Features of Gunny Bag Stitching Machines

Modern gunny bag stitching machines come with several advanced features that enhance their functionality. One significant advancement is the use of an automatic threading system, which reduces downtime and increases productivity. Many machines also include adjustable speed settings, allowing operators to customize stitching speed based on the material and bag size.

gunny bag stitching machine

Another key feature is the versatility of these machines. Many gunny bag stitching machines can handle a range of bag sizes and styles, from small sacks to larger bags meant for bulk storage. This versatility makes them valuable in various sectors beyond agriculture, including construction and textiles.

Additionally, many models now incorporate digital technology for enhanced control and monitoring. With digital displays and automated settings, operators can achieve greater precision in their stitching processes, reducing the likelihood of errors that could compromise the quality of the bags.

The Role of Gunny Bag Stitching Machines in Sustainability

As the world moves towards more sustainable practices, the role of gunny bag stitching machines in promoting eco-friendly packaging solutions cannot be overlooked. Gunny bags, particularly those made from jute, are biodegradable and biodegradable, making them an attractive alternative to plastic bags. The efficient stitching machines ensure that these bags are produced in large quantities, promoting the use of sustainable materials in various industries.

Moreover, the durability of properly stitched gunny bags means that they can be reused multiple times, contributing further to environmental conservation efforts. By reducing reliance on single-use plastic bags, industries can play a significant role in minimizing their ecological footprint.

Conclusion

Gunny bag stitching machines are more than just industrial tools; they are essential components that support the packaging and transport industries. Their ability to produce durable, reliable, and sustainable gunny bags makes them invaluable as we move towards a more eco-friendly approach in various sectors. By automating and enhancing the stitching process, these machines not only improve productivity but also ensure that products are safely contained and protected during storage and transport. As innovation continues to evolve within this field, the future of gunny bag stitching machines appears bright, promising even more efficiency and sustainability in packaging solutions.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025