Fév . 03, 2025 00:44

Back to list

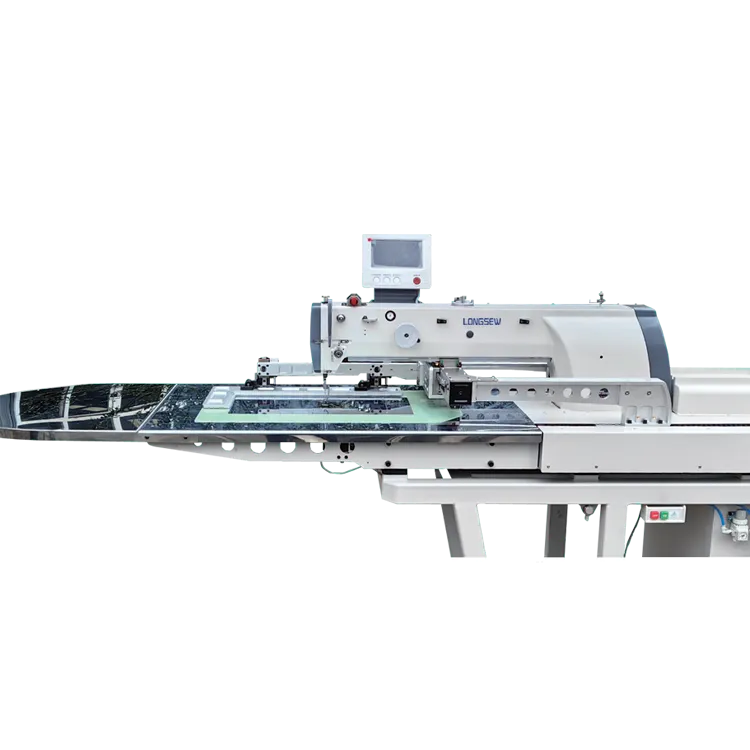

fully automatic sewing machine

For those seeking innovation in the textile industry, the fully automatic sewing machine represents a remarkable leap forward in crafting precision garments with minimal effort. Embracing technology that seamlessly blends human creativity with automated proficiency, these machines are transforming the landscape of fashion production globally.

Authoritativeness in the realm of modern textile engineering is underscored by the integration of digital interfaces and IoT capabilities within fully automatic sewing machines. Leading brands have developed platforms where machines can be monitored remotely, allowing for real-time adjustments and diagnostics. This connectivity ensures maintenance issues are promptly addressed, minimizing downtimes and enhancing overall productivity. The seamless integration of software updates further extends the machinery's lifespan, underscoring a commitment to both sustainability and cutting-edge innovation. Trustworthiness, arguably the most crucial pillar, is reinforced through rigorous testing and quality control protocols. Reputable manufacturers detail their commitment to producing reliable products through certifications and compliance with international safety standards. Prospective buyers should prioritize machines from established brands with well-documented support frameworks and customer service excellence. In doing so, they ensure their investment is backed by both a robust warranty policy and continuous technical support, essential for long-term productivity and cost-effectiveness. In conclusion, fully automatic sewing machines represent a paradigm shift in fashion manufacturing, harmonizing traditional craftsmanship with modern technological capabilities. As industries continue to embrace these innovations, sewers enjoy unprecedented creativity freedom, reliability, and efficiency. Whether for a large-scale factory or a small design studio, investing in an automatic sewing machine symbolizes a commitment to quality, precision, and the future of fashion itself. When selecting a fully automatic sewing machine, trust in performance, authority in engineering, and dedication to continual improvement should guide decision-makers toward sustainable textile excellence.

Authoritativeness in the realm of modern textile engineering is underscored by the integration of digital interfaces and IoT capabilities within fully automatic sewing machines. Leading brands have developed platforms where machines can be monitored remotely, allowing for real-time adjustments and diagnostics. This connectivity ensures maintenance issues are promptly addressed, minimizing downtimes and enhancing overall productivity. The seamless integration of software updates further extends the machinery's lifespan, underscoring a commitment to both sustainability and cutting-edge innovation. Trustworthiness, arguably the most crucial pillar, is reinforced through rigorous testing and quality control protocols. Reputable manufacturers detail their commitment to producing reliable products through certifications and compliance with international safety standards. Prospective buyers should prioritize machines from established brands with well-documented support frameworks and customer service excellence. In doing so, they ensure their investment is backed by both a robust warranty policy and continuous technical support, essential for long-term productivity and cost-effectiveness. In conclusion, fully automatic sewing machines represent a paradigm shift in fashion manufacturing, harmonizing traditional craftsmanship with modern technological capabilities. As industries continue to embrace these innovations, sewers enjoy unprecedented creativity freedom, reliability, and efficiency. Whether for a large-scale factory or a small design studio, investing in an automatic sewing machine symbolizes a commitment to quality, precision, and the future of fashion itself. When selecting a fully automatic sewing machine, trust in performance, authority in engineering, and dedication to continual improvement should guide decision-makers toward sustainable textile excellence.

Previous:

Latest news

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025