Foot Attachments for Industrial Sewing Machines Enhancing Efficiency and Precision

Understanding Foot Percentages for Industrial Sewing Machines

In the world of industrial sewing, the efficiency and quality of stitching are vital to production rates and final product quality. One of the critical components that plays a significant role in these metrics is the sewing machine’s presser foot. The term foot percentage in the context of industrial sewing machines refers to the proportion of different presser feet used relative to the different types of work or seam types being produced. Understanding this concept is essential for optimizing production processes, maintaining equipment, and ultimately ensuring high-quality output.

What is a Presser Foot?

Before diving into foot percentages, it’s important to understand what a presser foot is. The presser foot is a small but crucial part of a sewing machine that holds the fabric in place while it is being stitched. Different types of presser feet are designed for specific types of sewing tasks, such as straight stitching, zig-zag stitching, embroidery, or quilting. Each type of foot serves to facilitate different sewing techniques, help in controlling the fabric feed, and enhance the overall sewing experience.

Importance of Foot Percentages

In an industrial setting, varying sewing tasks often demand different presser feet. Therefore, analyzing foot percentages helps manufacturers determine which types of presser feet are most commonly used for their particular sewing processes. This not only aids in inventory management but also helps in training operators, as ensuring that the right foot is used for the right task can significantly reduce errors and improve productivity.

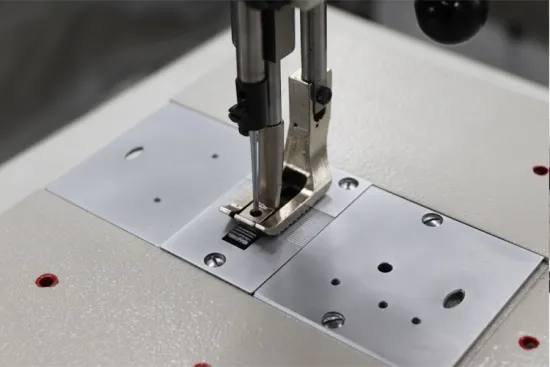

foot for industrial sewing machine

For example, a facility that predominantly produces denim products may find that a walking foot is essential due to its ability to handle multiple layers of thick fabric. Conversely, a facility focused on lightweight fabrics may use a more delicate foot, such as a teflon or satin foot. Keeping track of these foot percentages allows management to make informed decisions about which presser feet to stock and rely on for various jobs.

Optimizing Production with Foot Percentages

By analyzing the foot percentages in an industrial setting, a company can identify trends and adjust their operations accordingly. For instance, if a particular type of foot is used excessively, it might indicate a need for additional training for operators to improve efficiency or showcase the necessity of investing in more specialized machinery that suits the specific needs of production.

Furthermore, this analysis can also lead to innovations in process improvement. For example, if a company finds that the majority of their sewing operations require a certain type of presser foot, they might explore creating a dedicated sewing line that uses machines equipped specifically with that foot. This focused approach can lead to increased production speed and reduced downtime associated with changing foot types.

Conclusion

Understanding foot percentages for industrial sewing machines is more than just an exercise in efficiency; it is a critical factor that can influence the entire production process. By closely monitoring which presser feet are most used within a manufacturing facility, businesses can optimize their operations, reduce mistakes, and ultimately improve the quality of their products. As industries continue to evolve and become increasingly competitive, leveraging every tool and technique for efficiency—including the strategic use of presser feet—becomes imperative. In conclusion, a keen awareness of foot percentages can lead to significant enhancements in industrial sewing operations, making it an important area of focus for manufacturers and operators alike.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025