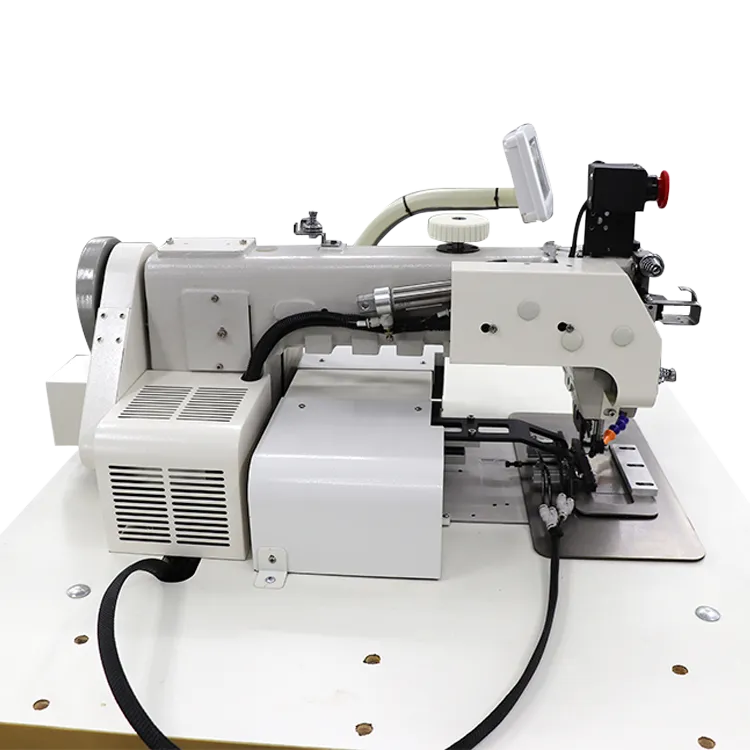

fibc computerized auto sew

Exploring the Future of FIBC Manufacturing with Computerized Auto Sewing Technology

In the ever-evolving world of manufacturing, the demand for efficiency, precision, and quality is at an all-time high. One of the most significant advancements in this field is the integration of computerized auto sewing technology, particularly in the production of Flexible Intermediate Bulk Containers (FIBCs). This innovative approach not only streamlines the manufacturing process but also enhances the overall quality of the products, positioning businesses at the forefront of competitive markets.

Exploring the Future of FIBC Manufacturing with Computerized Auto Sewing Technology

The benefits of computerized auto sewing technology extend beyond just efficiency. These machines are equipped with sophisticated software that allows for precise pattern programming, ensuring that each stitch is perfectly aligned. This level of accuracy is crucial for maintaining the integrity of FIBCs, particularly as they often need to withstand heavy loads and challenging transportation conditions. As a result, businesses that implement this technology can enhance product quality, leading to increased customer satisfaction and fewer returns.

fibc computerized auto sew

Moreover, computerized sewing systems offer flexibility in design. Manufacturers can easily modify sewing patterns to accommodate various sizes and specifications of FIBCs, all without the need for extensive retooling. This adaptability is essential in today’s fast-paced market, where customer demands can shift rapidly. With the ability to quickly adjust production lines to meet different requirements, companies can stay ahead of trends and fulfill customer orders more efficiently.

The integration of computerized auto sewing technology also contributes to sustainability in manufacturing. By optimizing the use of materials and reducing waste, businesses can operate more environmentally responsibly. Additionally, the consistency in sewing quality minimizes the likelihood of product failure, which ultimately reduces the resources required for replacements and repairs.

In conclusion, the adoption of computerized auto sewing technology in the FIBC manufacturing industry represents a significant leap forward. This innovation not only enhances efficiency and accuracy but also reinforces product quality and sustainability. As manufacturing continues to embrace automation and smart technology, companies that invest in these advanced systems position themselves for success in an increasingly competitive landscape. The future of FIBC production looks promising, with computerized auto sewing leading the way toward greater productivity and enhanced customer satisfaction.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025