Feeder Foot Sewing Machine for Precision and Efficiency in Fabric Handling

The Feeder Foot Sewing Machine A Versatile Tool for Seamstresses

The evolution of sewing technology has revolutionized the way garments and textiles are created, resulting in enhanced efficiency and precision. One of the standout innovations in this realm is the feeder foot sewing machine, a critical tool for both amateur and professional seamstresses. This article explores the features, benefits, and applications of feeder foot sewing machines, highlighting their versatility and importance in the textile industry.

Understanding Feeder Foot Sewing Machines

At its core, a feeder foot sewing machine is designed to facilitate the smooth feeding of fabric through the sewing process. Unlike traditional sewing machines that rely solely on the machine's feed dogs to move the fabric, feeder foot machines incorporate a specialized foot that can guide materials more effectively, allowing for a more consistent stitch quality. The feeder foot can hold, lift, and move the fabric in a synchronized manner with the needle, resulting in better control over fabric layers and patterns.

Features and Benefits

One of the primary features of a feeder foot sewing machine is its ability to handle a variety of fabric types, from delicate silks to heavy denims. The adjustable pressure and feeding mechanisms allow seamstresses to customize their settings based on the material being used. This adaptability makes the feeder foot machine an essential tool for quilters, tailors, and fashion designers who work with diverse textiles.

Moreover, the feeder foot enhances the overall sewing quality by reducing fabric puckering and distortion. When sewing multiple layers or intricate designs, the risk of uneven feeding can lead to disastrous results. The feeder foot mitigates this issue by ensuring that all layers are fed through the machine at the same rate, creating neat and professional-looking seams.

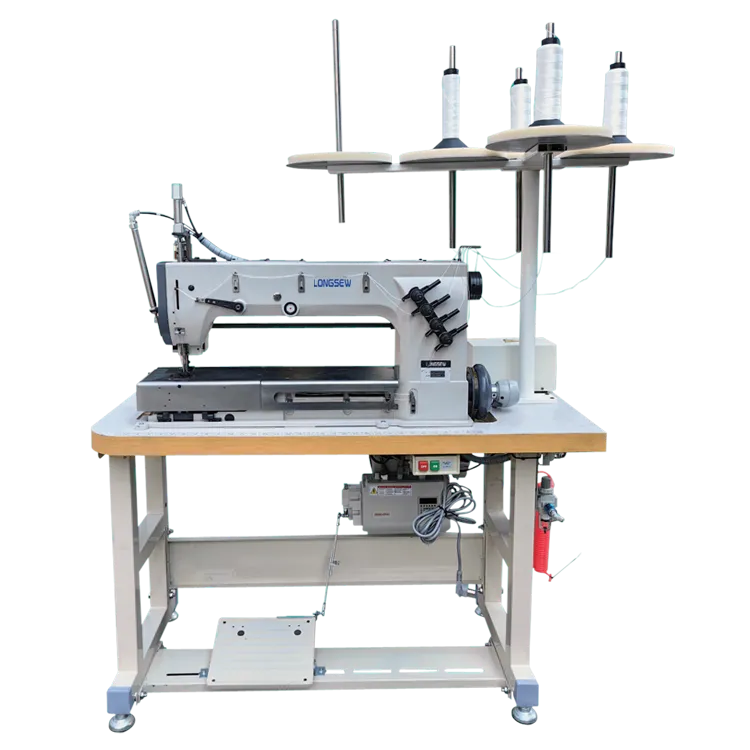

feeder foot sewing machine

Another significant advantage is the time savings offered by feeder foot sewing machines. With their efficient feeding mechanism, seamstresses can sew faster without compromising quality. This results in increased productivity, especially for those who are working on tight deadlines or large projects.

Applications in the Textile Industry

Feeder foot sewing machines find applications in various sectors within the textile industry. In garment manufacturing, they are essential for tasks such as attaching collars, cuffs, and hems, where multiple fabric layers come together. The consistent feed allows garments to be produced with precision, ensuring that every piece meets quality standards.

In the realm of quilting, feeder foot machines are particularly valuable. Quilters often work with multiple layers of fabric and batting, making it crucial to maintain accuracy throughout the sewing process. The feeding capabilities of feeder foot machines help to achieve beautifully stitched patterns without the frustrations that can come from fabric shifting.

Furthermore, these machines are also used in upholstery work, where heavy materials require careful handling. The feeder foot ensures that bulky fabrics are fed smoothly through the machine, allowing upholsterers to create stunning pieces of furniture without the hassle of uneven seams.

Conclusion

The feeder foot sewing machine is a remarkable tool that has significantly impacted the world of sewing. Its ability to handle various fabrics with precision, improve stitch quality, and enhance productivity makes it an invaluable asset for seamstresses across different fields. As technology continues to advance, it is exciting to imagine how these machines will evolve, further streamlining the sewing process and enabling creatives to bring their visions to life with greater ease and accuracy. Whether you are a hobbyist or a professional, investing in a feeder foot sewing machine can undoubtedly elevate your sewing experience.

-

Heavy Duty Leather Sewing Machine: A Must-Have for Professional LeatherworkNewsMay.28,2025

-

Leather Sewing Machine: Essential for High-Quality LeathercraftNewsMay.28,2025

-

Extra Heavy Duty Sewing Machine for Premium Leather ApplicationsNewsMay.28,2025

-

Walking Foot Cylinder Arm Sewing Machine: Precision and Power CombinedNewsMay.28,2025

-

Industrial Cylinder Arm Sewing Machine: Engineered for High-Performance StitchingNewsMay.28,2025

-

Cylinder Bed Sewing Machine: A Powerful Solution for Precision StitchingNewsMay.28,2025

-

Zigzag Sewing MachineNewsMay.12,2025