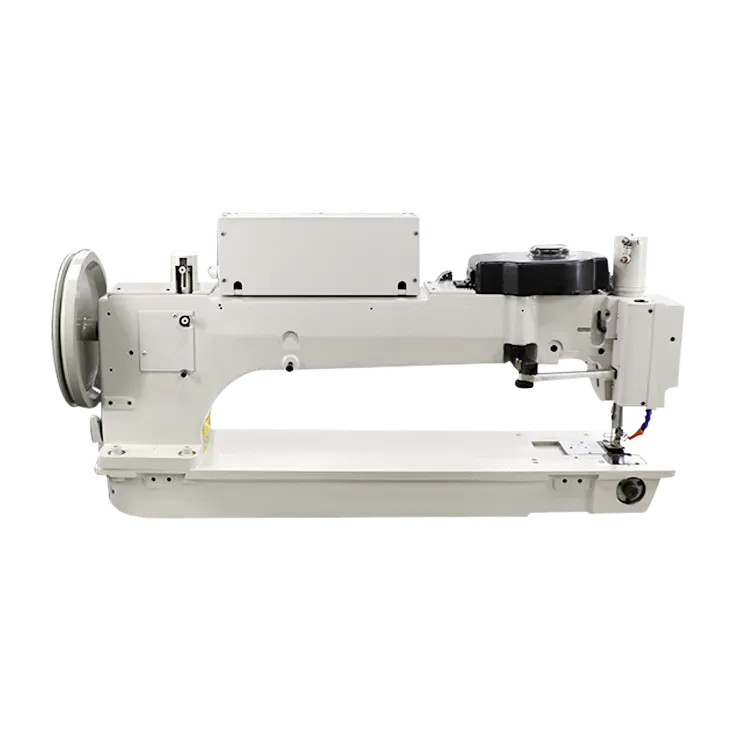

Versatile Double Needle Sewing Machine for Professional and Home Use

The Double Sewing Machine A Revolution in Textile Production

The world of textiles has evolved significantly since the days of hand-stitching, and at the forefront of this evolution is the double sewing machine. This innovative machine represents a critical advancement in the fashion and textile industry, bridging the gap between craftsmanship and efficiency. Understanding the features, advantages, and applications of double sewing machines sheds light on how they have revolutionized garment manufacturing.

What is a Double Sewing Machine?

A double sewing machine, often referred to as a double-needle sewing machine, utilizes two needles working simultaneously. This design allows for the creation of parallel seams that are both functional and aesthetically pleasing. Unlike traditional single-needle machines, which create a single line of stitching, double-needle machines can sew two rows of stitches with one operation, thereby speeding up the production process while ensuring high-quality results.

Key Features and Mechanisms

Double sewing machines come equipped with several distinctive features that enhance their functionality. One of the most significant is the dual needle system, which can work with varying needle gauges to create different stitch widths. Additionally, these machines often include adjustable stitch lengths and tensions, giving operators the flexibility to adapt to diverse fabric types and thicknesses.

Another critical aspect of double sewing machines is their ability to perform various stitch types, including straight, zigzag, and decorative stitches. This versatility makes them suitable for a wide range of applications, from crafting simple hems to intricate embroidery designs. Many modern double sewing machines also feature computerized controls, allowing for precise adjustments and easy operation.

Advantages of Using Double Sewing Machines

double sewing machine

The primary advantage of a double sewing machine is efficiency. With the ability to perform two seams simultaneously, these machines significantly reduce production time, allowing manufacturers to produce more garments in less time. This efficiency is particularly beneficial in the fast-paced fashion industry, where speed-to-market is crucial.

Moreover, double sewing machines enhance the quality of the finished product. The parallel stitching produced by these machines not only adds durability to seams but also contributes to refined aesthetics, making garments more appealing to consumers. This ability to combine functionality with style is essential in an industry where consumer preferences are continually evolving.

Cost-effectiveness is another notable advantage. While the initial investment in a double sewing machine may be higher than a single-needle machine, the boost in productivity and the reduction in labor costs lead to substantial long-term savings. Manufacturers can allocate resources more effectively, focusing on quality control and innovative design rather than repetitive stitching tasks.

Applications in the Fashion Industry

Double sewing machines have found applications across various segments of the fashion industry. From garment manufacturing to activewear and denim production, these machines are instrumental in achieving the durability and style that modern consumers demand. In particular, double-needle stitching is commonly used in the production of jeans, where the strength of the seams is essential for long-lasting wear.

Additionally, the use of double sewing machines extends beyond traditional apparel. They are also employed in the production of home textiles, such as curtains, upholstery, and bedding. The versatility of double sewing machines allows fashion designers and manufacturers to experiment with different materials and stitching techniques, fostering creativity and innovation in product development.

Conclusion

In conclusion, the double sewing machine symbolizes a transformative step in the textile and fashion industry. Its dual-needle system enhances efficiency, quality, and cost-effectiveness, empowering manufacturers to meet the demands of a dynamic market. As technology continues to evolve, we can expect further advancements in sewing machines, making them even more crucial in the crafting of beautiful and durable garments. The double sewing machine not only enhances production capabilities but also allows designers to focus on creativity, ultimately shaping the future of fashion. Whether in high-end couture or everyday wear, the impact of double sewing machines will continue to resonate throughout the industry, guiding the way for innovation and excellence in textile production.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025