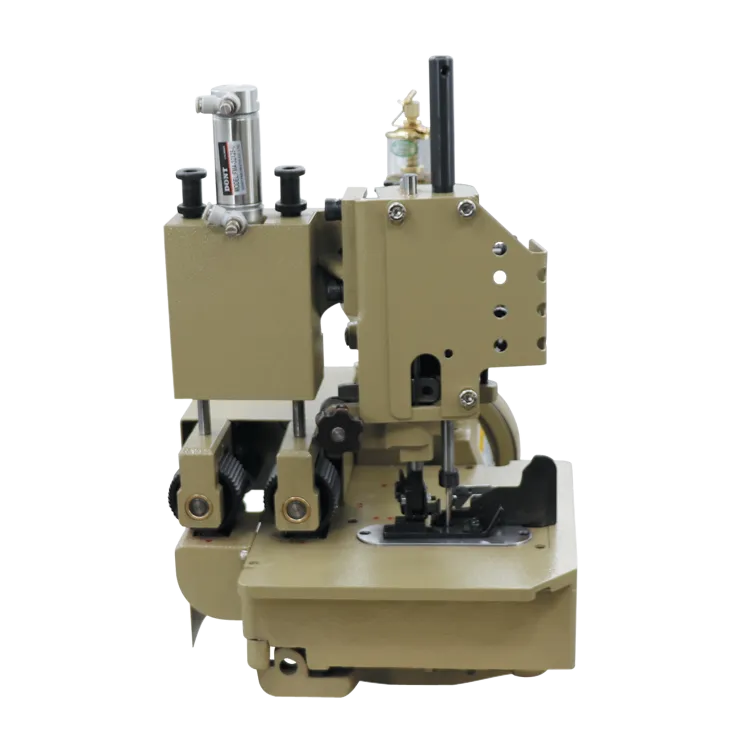

Cylinder Bed Sewing Machine for Industrial Applications and Versatile Fabric Handling

The Benefits and Features of Cylinder Bed Industrial Sewing Machines

In the realm of industrial sewing machinery, cylinder bed sewing machines stand out for their unique design and functionality. Unlike traditional flatbed machines, cylinder bed models have a cylindrical arm, creating a workspace that is perfect for sewing curvatures and cylindrical objects. This article delves into the various benefits, features, and applications of cylinder bed industrial sewing machines, showcasing why they are indispensable in various sectors of the textile industry.

Enhanced Versatility

One of the most significant advantages of cylinder bed sewing machines is their versatility. The cylindrical arm allows for easier manipulation of materials, particularly when sewing sleeves, cuffs, collars, and other tubular items. This feature makes them particularly valuable in the garment manufacturing sector, enabling workers to sew complex patterns and details with precision and ease.

For businesses that engage in high-volume production of apparel, the ability to effortlessly sew cylindrical items without the restrictions of a flatbed machine can lead to increased efficiency and reduced turnaround times. The flexibility offered by these machines also opens up avenues for creative design, allowing for intricate detailing that enhances the final product.

Precision and Quality

Another critical benefit of cylinder bed industrial sewing machines is the level of precision they offer. The design of these machines reduces fabric distortion, which is often a challenge when using flatbed machines. As the fabric is guided around the cylindrical arm, there is less risk of puckering or uneven seams, leading to higher-quality finished products. This precision is essential in industries where even the slightest deviation can lead to significant financial repercussions.

In addition, many cylinder bed sewing machines come equipped with advanced features such as automatic thread trimming, stitch control, and differential feed. These features not only enhance the machine's precision but also contribute to a seamless sewing experience. As a result, manufacturers can produce garments that meet high standards, ensuring customer satisfaction and brand loyalty.

cylinder bed industrial sewing machine

Durability and Reliability

Industrial sewing machines are built for heavy-duty usage, and cylinder bed machines are no exception. They are constructed with robust materials and powerful motors, allowing them to withstand the rigors of continuous operation. This durability translates into lower maintenance costs and longer machine lifespans, making them a wise investment for businesses in the textile industry.

Moreover, the reliability of cylinder bed machines is paramount

. These machines are designed for high-speed sewing, capable of handling large volumes of fabric without compromising on quality. This capability ensures that manufacturers can keep up with demand while maintaining consistent output quality.Applications in Various Industries

The applications of cylinder bed industrial sewing machines extend beyond the garment sector. They are widely used in upholstery, leather goods production, and the manufacturing of technical textiles. For instance, in the upholstery industry, these machines are ideal for sewing curved patterns in furniture, while in leather goods production, they can handle intricate stitching on handbags and belts.

In the world of technical textiles, where specialized materials are used for products like sports gear and protective clothing, the precise control offered by cylinder bed machines becomes even more crucial. The ability to manipulate different types of fabric, from heavy-duty materials to delicate textiles, makes these machines a versatile choice across diverse applications.

Conclusion

In summary, cylinder bed industrial sewing machines offer numerous advantages that make them essential for modern manufacturing. Their versatility, precision, durability, and wide range of applications across various industries contribute to their popularity in the textile world. For businesses looking to enhance their production capabilities and maintain high-quality standards, investing in a cylinder bed sewing machine is a strategic move. As the textile industry continues to evolve, these machines will undoubtedly play a pivotal role in driving innovation and quality in garment production and beyond.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025