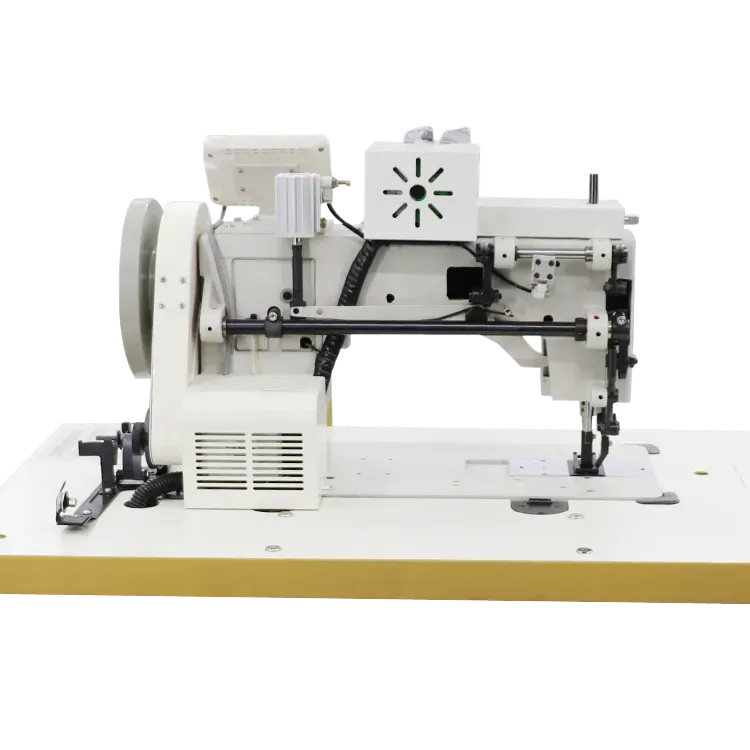

compound feed heavy duty sewing machine

The Compound Feed Heavy Duty Sewing Machine A Backbone of Industrial Sewing

In the realm of industrial sewing, the compound feed heavy duty sewing machine stands out as a vital tool for manufacturers. Known for its durability and robust construction, this machine is designed to handle a wide variety of fabrics, making it essential in industries such as apparel, upholstery, and leather goods.

One of the primary features that set the compound feed heavy duty sewing machine apart is its feeding mechanism. Unlike standard sewing machines, which often rely on a single feed mechanism, compound feed machines utilize a combination of multiple feeding methods. This includes the needle feed, walking foot, and bottom feed, allowing for superior material handling and precise stitching. This compound action ensures that even thick or layered fabrics are moved evenly through the machine, thereby reducing the chances of fabric slippage and ensuring consistent stitch quality.

Another significant advantage of these machines is their ability to work with heavy-weight materials. The compound feed heavy duty sewing machine can easily sew through materials such as denim, canvas, and leather without compromising the integrity of the stitch. This capability makes it the preferred choice for manufacturers who produce outdoor gear, heavy-duty clothing, and custom upholstery.

compound feed heavy duty sewing machine

Moreover, the durability of these machines is a critical aspect to consider. Constructed with high-quality materials and designed to withstand the rigors of industrial usage, the compound feed heavy duty sewing machine can operate for extended hours without a hitch. This resilience translates to lower maintenance costs and increased productivity, allowing businesses to meet tight deadlines without worrying about machine breakdowns.

The versatility of the compound feed heavy duty sewing machine also plays a significant role in its popularity. With adjustable stitch lengths, varying presser foot heights, and different needle sizes, users can easily customize the machine settings to suit different projects. This flexibility empowers sewers to take on a diverse range of tasks, from intricate designs to straightforward straight stitching.

User-friendliness is another element that cannot be overlooked. Many modern compound feed heavy duty sewing machines come equipped with intuitive controls and easy-to-navigate interfaces, making them accessible for both seasoned professionals and newcomers in the sewing industry. Furthermore, manufacturers are increasingly integrating advanced technology into these machines, such as automatic thread cutters and programmable stitch patterns, enhancing efficiency even further.

In conclusion, the compound feed heavy duty sewing machine is an indispensable asset in the landscape of industrial sewing. Its blend of strength, versatility, and user-friendly design allows manufacturers to produce high-quality products efficiently. Whether you’re tackling heavy fabrics or intricate designs, investing in a compound feed heavy duty sewing machine can greatly elevate your sewing capabilities, ensuring that your business remains competitive in a dynamic market. As industries continue to evolve, this machine will undoubtedly remain a key player in the advancement of sewing technology.

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025

-

Revolutionizing Efficiency with Automatic Sewing MachinesNewsMar.28,2025

-

Mastering Precision with Sewing Machines and ToolsNewsMar.28,2025

-

Mastering Precision with Double Needle and Chain Stitch Sewing MachinesNewsMar.28,2025

-

Leather Sewing Machines for Every NeedNewsMar.28,2025

-

Find the Best Deals on the Adler 205 370 Sewing MachineNewsMar.28,2025

-

The Essential Guide to Overlock Sewing MachinesNewsMar.18,2025