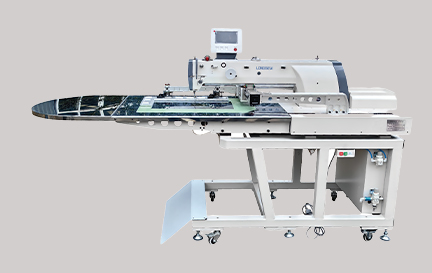

Advanced CNC Pattern Sewing Machine for Precision Fabric and Design Automation

CNC Pattern Sewing Machines Revolutionizing Textile Manufacturing

In the realm of textile manufacturing, the rise of technology has brought forth innovative solutions that streamline processes and enhance productivity. One such advancement is the Computer Numerical Control (CNC) pattern sewing machine, a device that is transforming how garments and textiles are produced. By leveraging automation and digital precision, these machines are enabling manufacturers to operate more efficiently while maintaining high standards of quality.

Understanding CNC Technology

CNC technology involves the use of computers to control machine tools and processes. In the context of sewing, CNC pattern machines are equipped with software that allows users to create intricate patterns and designs digitally. By inputting design specifications into the machine’s software, operators can select from a range of stitches, fabrics, and sewing techniques, resulting in precise and consistent outputs that would be challenging to achieve manually.

The CNC sewing machine vastly improves the traditional sewing process, which often relies on skilled workers to interpret patterns and execute them by hand. With CNC technology, manufacturers can achieve a higher level of accuracy and repeatability, leading to a significant reduction in material waste and production time.

Advantages of CNC Pattern Sewing Machines

1. Increased Productivity CNC machines can operate at a much faster rate than human operators. This efficiency allows manufacturers to fulfill larger orders in a shorter time frame, thereby responding more rapidly to market demands.

2. Precision and Consistency The inherent accuracy of CNC machines ensures that each piece produced is nearly identical to the last. This level of consistency is vital in the fashion industry, where discrepancies in size and design can lead to costly returns and dissatisfied customers.

3. Design Flexibility CNC sewing machines enable designers to experiment with more intricate and complex patterns. The software allows for easy modifications, making it simple to tweak designs without having to start over from scratch. This flexibility fosters creativity and innovation in textile design.

cnc pattern sewing machine

4. Reduced Labor Costs While the initial investment in CNC machinery may be significant, the reduction in labor costs can be substantial. Fewer skilled workers are needed on the factory floor, as the machine can handle many tasks autonomously, allowing staff to focus on higher-level operations.

5. Material Optimization CNC machines are programmed to use fabric more efficiently. With precise cutting and stitching, these machines minimize waste, which is beneficial not only for manufacturers but also for the environment. This aspect of operation aligns with the growing trend of sustainability in the fashion industry.

Challenges and Considerations

Despite the numerous advantages of CNC pattern sewing machines, there are challenges that manufacturers must navigate. The upfront cost of purchasing and setting up CNC equipment can be daunting, particularly for small businesses. Additionally, a skilled workforce is still required to operate and maintain the technology effectively. Training staff to understand the complexities of CNC programming and operation is crucial for maximizing the benefits of the machinery.

Moreover, the integration of CNC technology requires careful planning and a shift in production strategies. Manufacturers may need to reevaluate their workflows and processes to incorporate CNC seamlessly into their production lines.

The Future of CNC Sewing in Textiles

The future of CNC pattern sewing machines looks promising as advancements in technology continue to evolve. Innovations such as artificial intelligence and machine learning have the potential to further enhance the capabilities of CNC machines, allowing for smarter production systems that can adapt to changing design trends and customer preferences.

Furthermore, as sustainability becomes an increasingly important focus in the textile industry, CNC machines will play a significant role in promoting eco-friendly practices. Manufacturers that adopt this technology will not only benefit from increased efficiency but also contribute to a more sustainable future.

In conclusion, CNC pattern sewing machines are revolutionizing the textile manufacturing landscape. Their ability to combine speed, precision, and flexibility makes them an invaluable asset for modern manufacturers. As the industry continues to adapt to technological advancements, CNC machines will undoubtedly lead the way in shaping the future of clothing production and design. Embracing this innovation is not just a step forward for efficiency—it is a leap toward a more sustainable and creative textile industry.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025