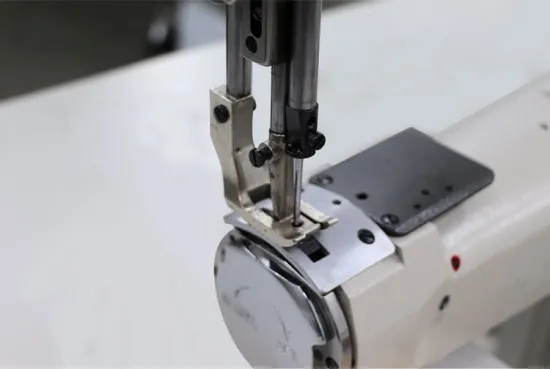

bulk bag sewing machine

The Importance of Bulk Bag Sewing Machines in Modern Manufacturing

In the fast-paced world of manufacturing and packaging, efficiency and precision are paramount. One of the crucial components in this sector is the bulk bag sewing machine. These machines play an essential role in the production of bulk bags, which are widely used for transporting and storing a variety of products, ranging from agricultural products to industrial materials. This article delves into the significance of bulk bag sewing machines and their impact on efficiency and productivity.

Bulk bags, also known as FIBCs (Flexible Intermediate Bulk Containers), are designed to hold large quantities of materials. They are typically made from woven polypropylene, which provides strength and durability. The sewing of these bags is a critical process that ensures they can safely hold and transport the contents without risk of spillage or breakage. This is where bulk bag sewing machines come into play.

These specialized sewing machines are designed to handle the specific requirements of bulk bag production. They are equipped with heavy-duty sewing capabilities that can manage thicker fabrics, ensuring strong seams that can withstand the rigors of transportation and handling. Additionally, these machines often feature automated functions that increase sewing speed and consistency, allowing manufacturers to produce bulk bags at a much faster rate than manual sewing would permit.

bulk bag sewing machine

One of the key advantages of using bulk bag sewing machines is the reduction in labor costs. Manual sewing processes are not only time-consuming but also require skilled labor, which can be hard to find and expensive to maintain. By incorporating bulk bag sewing machines into the production line, manufacturers can automate much of the sewing process, freeing up human resources for other tasks and significantly lowering operational costs.

Moreover, bulk bag sewing machines contribute to improved quality control. Automated machines can be programmed to maintain specific stitching patterns and tensions, minimizing the chances of human error. This results in consistently high-quality bags that meet the required standards for safety and durability. For industries that rely on the integrity of their bulk packaging, such as food, pharmaceuticals, and construction, this consistency is crucial.

The versatility of bulk bag sewing machines also deserves mention. They can be adapted to produce different types of bags according to the needs of the industry. Whether it’s for bulk transport of grain, chemicals, or other materials, these machines can be outfitted with various sewing attachments and features to customize the production process. This adaptability ensures that manufacturers can respond swiftly to market demands and changes.

In conclusion, bulk bag sewing machines are an invaluable asset to modern manufacturing operations. They enhance efficiency, reduce costs, and improve the quality of bulk bags produced. As industries continue to seek ways to optimize their operations and meet the growing demand for sustainable packaging solutions, the role of bulk bag sewing machines will undoubtedly become even more significant. Investing in these machines not only benefits manufacturers but also contributes to a more efficient and responsible supply chain, ultimately supporting a sustainable future.

-

Industrial Cylinder Arm Sewing Machine: Revolutionizing Heavy-Duty SewingNewsJul.28,2025

-

Cylinder Arm Sewing Machine: Perfect for Special Sewing ApplicationsNewsJul.28,2025

-

Cylinder Bed Sewing Machine: Essential for Sewing Complex MaterialsNewsJul.28,2025

-

Heavy Duty Sewing Machine: The Essential Tool for Industrial ApplicationsNewsJul.28,2025

-

Computerized Pattern Sewing Machine: Revolutionizing Precision StitchingNewsJul.28,2025

-

Heavy Duty Industrial Sewing Machine: Power Meets PrecisionNewsJul.28,2025

-

Leather Sewing Machine: The Industrial Standard for Tough MaterialsNewsJul.18,2025