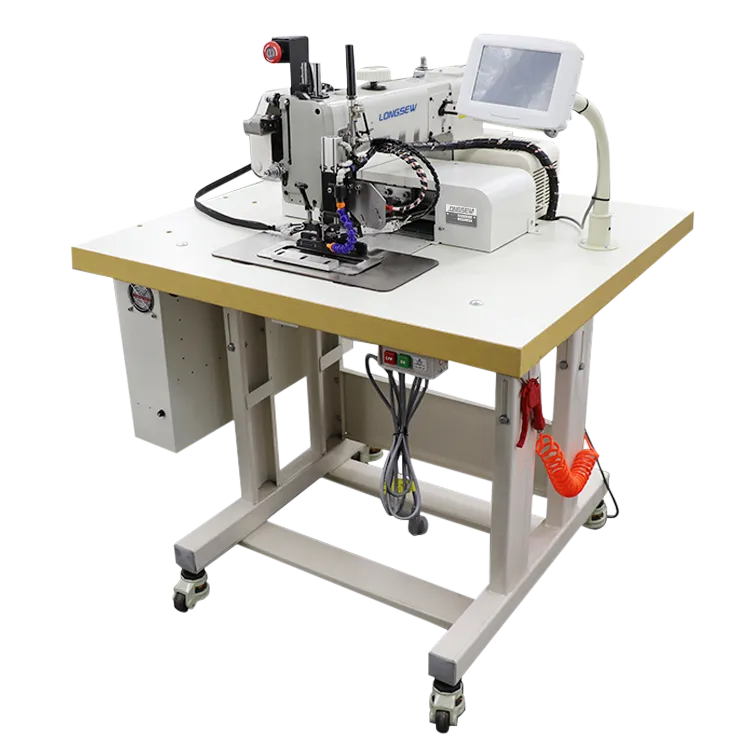

2 needle lockstitch machine

The Evolution and Significance of the 2% Needle Lockstitch Machine in Textile Manufacturing

In the dynamic world of textile manufacturing, the 2% needle lockstitch machine stands out due to its innovation and efficiency. As an intrinsic part of the sewing process, this machine employs a simple yet effective mechanism that has significantly transformed the way garments and fabric products are produced. The lockstitch technique, characterized by its durability and adaptability, facilitates seamless sewing that meets various industry demands.

Understanding the basic functioning of the 2% needle lockstitch machine is essential to appreciating its role in modern textile manufacturing. This machine operates using two threads the needle thread and the bobbin thread. The intricate interplay between these threads creates a tight and secure stitch through a needle that penetrates the fabric and a synchronized bobbin that secures the stitch from underneath. This mechanism not only ensures a strong seam but also minimizes thread tension issues that can often complicate the sewing process.

The Evolution and Significance of the 2% Needle Lockstitch Machine in Textile Manufacturing

Moreover, the 2% needle lockstitch machine has seen advancements in technology that further enhance its capabilities. Modern iterations often include programmable features, digital displays, and automated threading systems that simplify operation and improve productivity. These improvements have led to shorter production times and reduced labor costs, driving manufacturers to adopt such machines as part of their standard operational procedures.

2 needle lockstitch machine

In addition to efficiency and adaptability, the 2% needle lockstitch machine also plays a significant role in the sustainability of the textile industry. Traditional sewing methods often generate considerable waste, both in terms of materials and energy. However, the lockstitch technique promotes precise sewing, which minimizes fabric wastage and maximizes the output from raw materials. This not only benefits manufacturers’ bottom lines but also aligns with contemporary initiatives aimed at fostering sustainable production practices.

Furthermore, the durability of the lockstitch seam contributes to the longevity of the finished products. Garments and textiles produced using the 2% needle lockstitch machine exhibit enhanced resistance to wear and tear, thus prolonging their lifecycle. This characteristic is particularly crucial in an era where consumers increasingly prioritize quality and sustainability when making purchasing decisions.

Looking ahead, the future of the 2% needle lockstitch machine seems promising. With the ongoing integration of advanced technologies such as automation, artificial intelligence, and smart manufacturing practices, these machines are poised for further evolution. Enhanced integration with design software and smart factory systems will likely lead to even greater efficiency and customization in production processes.

In conclusion, the 2% needle lockstitch machine is a crucial innovation in textile manufacturing that has significantly contributed to the industry’s evolution. Its efficient, adaptable, and sustainable sewing capabilities set a high standard for quality and productivity. As technology advances and the industry evolves, the significance of the 2% needle lockstitch machine will undoubtedly continue to grow, reinforcing its status as a pivotal tool in textile manufacturing. The combination of traditional techniques with modern technology will ensure that this machine remains at the forefront of efficient and sustainable production for years to come.

-

Zigzag Sewing MachineNewsMay.12,2025

-

Single Needle Sewing MachineNewsMay.12,2025

-

Overlock Sewing Machine PriceNewsMay.12,2025

-

Heavy Duty Industrial Sewing MachineNewsMay.12,2025

-

FIBC Sewing MachineNewsMay.12,2025

-

Cylinder Bed Sewing MachineNewsMay.12,2025

-

Revolutionizing Sewing with CNC TechnologyNewsMar.28,2025