...

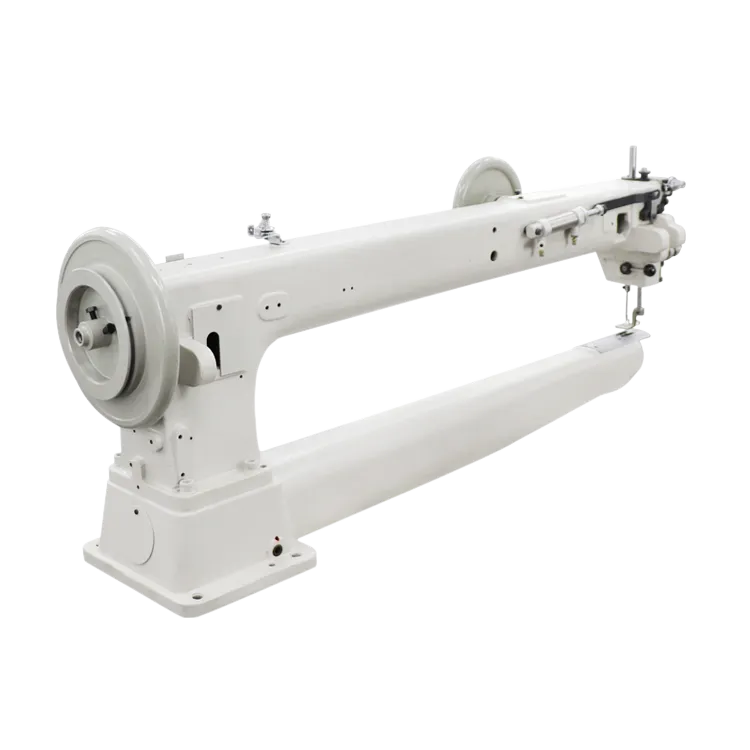

Bulk bag sewing machine 【Bulk bag sewing machine】

Read MoreOne of the primary benefits of a domestic lockstitch sewing machine is its ability to produce high-quality seams with ease. Whether it’s garment construction or home accessories, the lockstitch provides a professional finish that can withstand wear and washing. This machine is also economical, allowing individuals to repair or create garments, resulting in significant savings compared to purchasing new items.

...

Bulk bag sewing machine 【Bulk bag sewing machine】

Read MoreChanging needles regularly is important to avoid damage to the fabric and to maintain consistent stitch quality. It’s also advisable to use the correct type of needle for the fabric being sewn, as this will enhance both performance and stitch appearance.

...

Bulk bag sewing machine 【Bulk bag sewing machine】

Read MoreWhy Choose Heavy-Duty for Vinyl?

...

Bulk bag sewing machine 【Bulk bag sewing machine】

Read More...

Bulk bag sewing machine 【Bulk bag sewing machine】

Read MoreAdditionally, the price can be influenced by the machine's intended application. Some cylinder bed machines are designed for specific tasks, such as leather sewing or quilting, and may come with specialized features that cater to those needs. Consequently, these models may be priced higher than general-purpose machines.

...

Bulk bag sewing machine 【Bulk bag sewing machine】

Read More...

Bulk bag sewing machine 【Bulk bag sewing machine】

Read MoreGSC367TD is a transcription factor, meaning it binds to specific DNA sequences and regulates the transcription of nearby genes. Transcription factors like GSC367TD act as molecular switches, turning genes on or off in response to various signals within the cell.

...

Bulk bag sewing machine 【Bulk bag sewing machine】

Read MoreIn conclusion, a heavy-duty sewing machine is an excellent investment for beginners ready to explore the world of sewing. With their robust features and ability to handle a variety of materials, these machines can help foster creativity and enable the successful completion of many sewing projects. So take the plunge, discover the joys of sewing, and unleash your creativity with a heavy-duty sewing machine that meets your needs. Happy sewing!

...

Bulk bag sewing machine 【Bulk bag sewing machine】

Read MoreAnother factor that influences the price is the brand. Well-known brands with a reputation for quality and reliability, such as Brother, Singer, and Janome, may command higher prices. These brands often provide better customer support and warranties, which can be beneficial in the long run. Lesser-known or generic brands may offer more competitive pricing but could come with trade-offs in terms of quality and service.

...

Bulk bag sewing machine 【Bulk bag sewing machine】

Read More2. Machine Features The price can also vary greatly depending on the features included. Basic zigzag sewing machines might only offer the fundamental zigzag stitch, while more advanced models may come equipped with multiple stitch options, automatic threading, and digital displays. Machines with more features typically range at a higher price point but can offer greater convenience and versatility.

Conclusion

In conclusion, the zigzag sewing machine is an invaluable tool for anyone interested in the art of sewing. With its ability to produce a versatile range of stitches, handle various fabric types, and facilitate intricate design applications, it caters to both functional and creative needs. Whether you're stitching up a simple hem or embarking on a complex quilting project, a zigzag sewing machine can help you achieve professional results with ease. As sewing continues to grow as a popular hobby and profession, the zigzag sewing machine remains a timeless asset in any sewing toolkit.

Moreover, the versatility of the overlock chain stitch extends beyond clothing. It is often used in the production of home textiles, such as curtains and upholstery, where a neat finish and the ability to handle varying fabric types are required. This stitch can also be found in the crafting of accessories, like bags and hats, where strength and elasticity are vital.

The Art of Single Needle Top Stitch A Seamstress's Guide

It’s important for you to use a quality walking foot sewing machine that is easy to use, reasonably priced, durable, rugged, dependable, and has years of success. Here are the most important benefits to a walking foot sewing machine when sewing heavy duty fabrics such as leather, canvas, sailcloth, upholstery materials, strapping and more:

- Thread Bunching or Tension Issues This often means that the thread tension is not balanced. Adjust the tension settings on your machine and re-thread it if necessary.

Another important factor to consider when choosing an industrial overlocker is the ease of use and maintenance

Typically, the machine head employs methods such as stitching, heat sealing, or gluing to close the bags. Each method has its advantages depending on the type of bag and the contents that need protection. For example, heat sealing is particularly effective for plastic bags as it provides a strong and waterproof closure. On the other hand, stitching is suitable for fabric bags, delivering durability and resistance against tearing during transport.