1. Climate and environment conditions

...

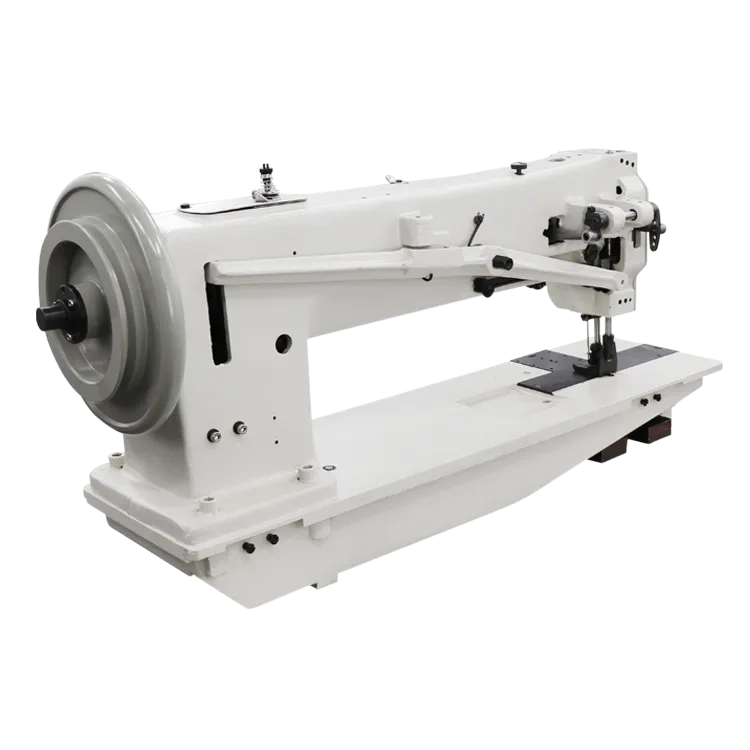

heavy sewing machine 【heavy sewing machine】

Read MoreTo perfect the single needle top stitching technique, one must consider several essential factors

...

heavy sewing machine 【heavy sewing machine】

Read More4. Technological Advancements

...

heavy sewing machine 【heavy sewing machine】

Read MoreThe first step in creating car mats is selecting the right materials. The most common fabrics include durable rubber, heavy-duty carpet, and even recycled materials for environmentally conscious creators. Rubber mats provide excellent water resistance and easy cleaning, while heavy-duty carpet can add a touch of style and comfort.

...

heavy sewing machine 【heavy sewing machine】

Read More4. Time-Saving Efficiency With two needles working at once, sewing time can be significantly reduced, allowing users to complete projects more quickly. This efficiency is particularly advantageous in a commercial setting where turnaround time is crucial.

...

heavy sewing machine 【heavy sewing machine】

Read MoreWhen choosing between a handheld sewing machine and a heavy-duty one, price is a significant factor to consider. Handheld machines tend to be more affordable and are an excellent entry point for beginners on a budget. However, if you plan to tackle substantial projects regularly, investing in a heavy-duty machine may be a cost-effective choice in the long run, as it can handle a wider range of tasks and materials.

...

heavy sewing machine 【heavy sewing machine】

Read MoreThe journey of creating a leather item begins with careful planning. Designers often sketch their ideas or use templates to ensure precision. Once the pattern is established, the leather is cut with great attention to detail. The edges are typically beveled and finished to prevent fraying and to enhance the overall appearance.

...

heavy sewing machine 【heavy sewing machine】

Read MoreIn conclusion, the various parts of a bag closer machine play a pivotal role in the efficiency and effectiveness of packaging processes. Understanding each component's function not only aids in troubleshooting and maintenance but also highlights the importance of investing in high-quality parts. As the demand for efficient packaging continues to grow, the significance of reliable bag closer machines and their parts will remain critical to the success of manufacturing and packaging industries worldwide.

...

heavy sewing machine 【heavy sewing machine】

Read More3. Insert the Double Needle

...

heavy sewing machine 【heavy sewing machine】

Read More...

heavy sewing machine 【heavy sewing machine】

Read MoreMoreover, overlock machines are designed to handle heavy workloads. Unlike domestic sewing machines, which may struggle with thicker fabrics or multiple layers, industrial overlock machines are built to accommodate various materials, from lightweight jersey to heavy denim. This versatility makes them a favorite among manufacturers who produce a wide range of garment types.

3. Versatility Many industrial sewing machines come equipped with various attachments and features that allow for a wide range of sewing techniques. From straight stitching to zig-zag and overlock stitching, these machines can handle diverse sewing projects, making them ideal for quilters, garment makers, and craft enthusiasts.

Coverstitch chain stitching is predominantly used in the finishing process of hems, especially on knit fabrics. It is commonly found on t-shirts, leggings, jerseys, and activewear due to its ability to stretch and recover. However, its applications go beyond hems. The coverstitch can also be used for attaching bindings, reinforcing seams, or as a decorative feature on the surface of garments, making it a multifaceted addition to any sewing toolkit.

In conclusion, the hi-speed lockstitch sewing machine is a cornerstone of modern textile manufacturing. Its efficiency, consistency, and technological advancements not only boost productivity but also help address sustainability concerns. As the fashion and textile industries continue to evolve, the hi-speed lockstitch machine will undoubtedly play a critical role in shaping the future of garment production, offering opportunities for both innovation and improved operational effectiveness. Embracing this technology is essential for manufacturers aiming to thrive in an increasingly competitive marketplace.

The Creative Potential

As technology progresses, compound feed sewing machines are also evolving. Manufacturers are now incorporating advanced features such as digital control systems and automated adjustments, allowing for greater precision and customization. These innovations not only facilitate easier operation but also improve the overall quality of the stitching process.

One example is a sailor and his or her understanding that most new boats are going to need a ton of canvas or brightwork done over the years.

5. Safety Features Ensure that the machine has safety features, such as a blade cover or an automatic shut-off function to prevent accidents.

A heavy-duty sewing machine typically features a higher stitch-per-minute rate, which allows for quicker completion of projects. Many also come equipped with specialized needles and presser feet designed for various fabric types, enhancing versatility and efficiency in the sewing process.

Moreover, the floating foot offers unprecedented flexibility in terms of the types of fabric that can be used. Whether sewing lightweight silks or heavy upholstery, the machine adapts seamlessly, cutting down on the painstaking adjustments that often accompany traditional sewing methods. This versatility not only saves time but also encourages creativity by allowing artisans to experiment with a broader range of materials.

The Art of Blind Stitch Upholstery A Seamless Finish

At the forefront of any storage solution is its ability to keep valuables safe. Metal storage lock boxes greatly enhance security through their robust construction. Made from durable materials such as galvanized steel or aluminum, these boxes are resistant to rust, impact, and tampering. The addition of a lock hasp further elevates security by enabling the use of a padlock, allowing users to select a locking mechanism that best fits their security needs. Whether it’s for storing important documents, tools, or valuable collectibles, the metal storage lock box offers peace of mind with its strong security features.

long metal door handles. They serve as a bridge between the interior and exterior worlds, a transition point that sets the tone for what lies beyond. As fingers glide over their length, they evoke a sense of anticipation, a moment of pause before entering a new space.

long metal door handles. They serve as a bridge between the interior and exterior worlds, a transition point that sets the tone for what lies beyond. As fingers glide over their length, they evoke a sense of anticipation, a moment of pause before entering a new space. sliding screen roller replacement. If not, adjust your purchase accordingly. Insert the new roller into the assembly slot, ensuring it fits snugly. Replace any worn-out tracks or brackets as needed. Then, reattach the roller assembly to the door with the screws, tightening them securely but not overly tight to avoid damaging the material.

sliding screen roller replacement. If not, adjust your purchase accordingly. Insert the new roller into the assembly slot, ensuring it fits snugly. Replace any worn-out tracks or brackets as needed. Then, reattach the roller assembly to the door with the screws, tightening them securely but not overly tight to avoid damaging the material.This anodizing method often takes place in a tank with sulfuric acid and water solution. Once anodizing process is over, you can immerse the components in an optional coloring tank to attain the ideal deep black hue.

Second, what is the overall look or aesthetic of the aluminium window, such as the size of the openings and how many fixed or opening elements are required? Are you looking to retain the look of the original windows or completely change the appearance of the property?

Finally, a “post cap” is sometimes necessary to both improve the post’s visual aesthetics while preventing debris and rainwater from entering the hollow interior. Water infiltration can quickly trigger rust to start developing inside the iron fence post. Therefore, caps provide a straightforward way to avoid the issue.

Durability and Longevity

Overall, decorative cast iron elements are a timeless and elegant choice for adding beauty and charm to any space. Whether used in building facades, furniture, or art pieces, cast iron elements are sure to make a lasting impression. Their durability, versatility, and intricate designs make them a popular choice for architects, designers, and artists alike. So next time you're looking to add a touch of elegance to your home or building, consider incorporating decorative cast iron elements into your design.

In conclusion, understanding the various parts of wrought iron fences is crucial for homeowners considering this elegant option for their property. Each component—posts, rails, pickets, gates, finials, finishes, and accessories—contributes to the overall functionality, security, and beauty of the fence. By choosing the right combination of materials and designs, homeowners can create a stunning wrought iron fence that not only meets their practical needs but also enhances the overall curb appeal of their property. This investment in quality fencing can last for decades, making it a wise and stylish choice for any property owner.

While aluminum has its benefits, it simply can’t rival the elegance, robustness, and security that wrought iron offers. In short, if you’re in search of a fencing solution that offers a rich blend of beauty, longevity, and a fortress-like feel, wrought iron is the unbeatable choice.

Wrought iron is the epitome of strength and longevity in the world of fencing. We’re talking about a material that can withstand harsh weather conditions, from scorching heat to freezing cold.

Fence brackets are unique to wrought iron fences and often used to hold the fencing components to the posts. These slide over the rails, are set against the posts and are often then secured with a self-tapping screw to hold everything together. Aluminium fencing does not use brackets. Instead, rails are slid into punches in an aluminium post and then a self-tapping screw is driven through the post and into a rail inside it in order to secure everything.

It allows the metal to obtain full strength, elasticity, and hardness.

1. Climate and environment conditions