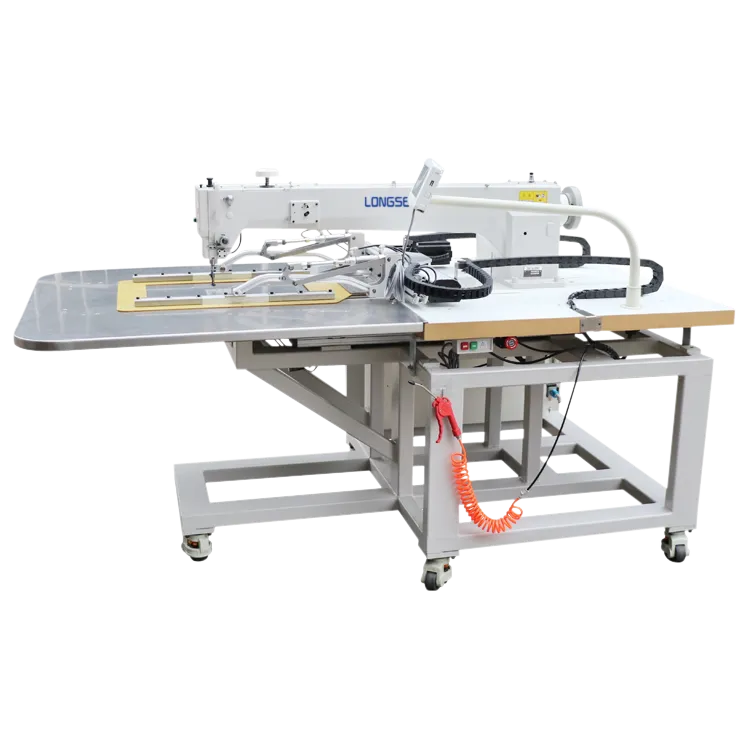

industrial sewing machine straight and zig zag

...

industrial sewing machine straight and zig zag 【industrial sewing machine straight and zig zag】

Read More4. Maintenance and Support Regular maintenance is crucial for overlocker longevity. Look for machines that are easy to maintain and have accessible customer support or local service centers.

industrial sewing machine straight and zig zag

...

industrial sewing machine straight and zig zag 【industrial sewing machine straight and zig zag】

Read MoreWhen determining the price of a sewing machine shuttle hook, it is important to consider the overall quality and durability of the hook. A high-quality shuttle hook made from durable materials will last longer and provide more reliable stitching than a cheaper, lower-quality hook. Investing in a quality shuttle hook may cost more upfront, but it can save you money in the long run by reducing the need for frequent replacements or repairs.

industrial sewing machine straight and zig zag...

industrial sewing machine straight and zig zag 【industrial sewing machine straight and zig zag】

Read MoreThe Essential Guide to Heavy-Duty Quilting Sewing Machines

industrial sewing machine straight and zig zag

...

industrial sewing machine straight and zig zag 【industrial sewing machine straight and zig zag】

Read MoreYou might need to adjust your thread tension. Start with your machine’s default settings and make minor adjustments if you observe any issues with the stitch.

industrial sewing machine straight and zig zag

...

industrial sewing machine straight and zig zag 【industrial sewing machine straight and zig zag】

Read MoreTraining staff to operate CNC programmable sewing machines is relatively straightforward, which can help businesses offset some of the labor shortages currently affecting the textile industry. While skilled operators are still essential for overseeing the machines and ensuring that they are functioning properly, the requirement for advanced sewing skills is diminished as workers can be trained to manage the software and machinery within a shorter timeframe.

industrial sewing machine straight and zig zag

...

industrial sewing machine straight and zig zag 【industrial sewing machine straight and zig zag】

Read More4. Cost-Effective Although the initial investment in an industrial overlocker may be higher than a standard sewing machine, the long-term benefits, including reduced labor costs and improved fabric usage, can lead to significant savings.

industrial overlocker for sale

industrial sewing machine straight and zig zag

...

industrial sewing machine straight and zig zag 【industrial sewing machine straight and zig zag】

Read More...

industrial sewing machine straight and zig zag 【industrial sewing machine straight and zig zag】

Read MoreQuilting, a timeless craft that intertwines fabric and creativity, has evolved in remarkable ways with the advent of technology. One of the most significant advancements in this field is the rise of quilting machine embroidery designs. These intricate and often stunning designs allow crafters to express their creativity while making the quilting process more efficient and accessible to a broader audience.

industrial sewing machine straight and zig zag

...

industrial sewing machine straight and zig zag 【industrial sewing machine straight and zig zag】

Read MoreThe technological advancements in automatic sewing machines also pave the way for innovative designs and features in shirt manufacturing. With the capability to execute intricate stitching patterns and specialized finishes, these machines allow designers to experiment with creativity without worrying about the limitations of manual sewing. As a result, the fashion industry can benefit from a diverse array of styles and designs, catering to a wide range of consumer preferences.

industrial sewing machine straight and zig zag

...

industrial sewing machine straight and zig zag 【industrial sewing machine straight and zig zag】

Read MorePopular articles

1. Online Retailers Websites like Amazon or specialized sewing supply stores offer a vast range of options. You can easily compare prices and read reviews from other users.

- Speed and Efficiency A serger can perform multiple tasks simultaneously—trimming, seaming, and finishing—which saves considerable time on sewing projects. This efficiency is particularly beneficial for small-scale manufacturers and designers.

The Growing Popularity of Serger Machine Sales

Overlockers are incredibly versatile, offering various stitch types to accommodate different fabric types and garment needs. The most common stitches include the 3-thread overlock, which is ideal for lightweight fabrics, and the 4-thread overlock, perfect for medium-weight materials. Additionally, overlockers can perform rolled hems, gathering stitches, and even flatlock stitches, making them invaluable for both home sewers and professional tailors.

3. Regular Maintenance Implementing a strict maintenance schedule can prevent costly breakdowns and ensure that machines always operate at optimal efficiency, thereby reducing per-hour costs.

3. Brand Reputation Research brands known for their reliability and support. Popular brands often have established service networks, which can be crucial for maintenance and repairs.

Latest articles

-

Projects and Materials Suitable for Heavy Duty Sewing Machines

-

The Versatility and Benefits of Raised Bed Sewing Machines

-

Links

- 5. Dry it with a towel.

The weight calculation method of hexagonal net is: the weight calculation method of hexagonal net: silk meridian.× silk meridian.× base x length x width ÷2=kg base: 1/2′=2.151′=1.273/4′=1.65/8′=1.875/4′=1.091′x1/2′ : 3′=0.4 silk warp. x silk warp. X 2x length x width ÷8×3=kg

- The principle of wire mesh mesh size, wire, square meters of steel content, galvanized amount, etc., to consider the corrosion resistance of wire mesh and the safety of the system! Wire mesh galvanized than wire diameter more fierce, galvanized quantity is very important, must be hot plating, welding after plating than plating after welding, as for wire diameter, induction and consideration of site construction and meet the needs of Ann.

3, reduce the bivalent iron ion in the plating aid used for hot plating wire, reduce the formation of zinc slag

- The quantity should be the same as the contract, cold drawing, carefully record the quantity of each specification and packing method. If there is a label, check whether the label is correct and take a photo to confirm. Each roll of iron wire is fastened with galvanized packing tape, and then tightly bound with a very strong transparent plastic bag. The outer layer of coated iron wire is wrapped with white braided cloth, and the outer layer of galvanized iron wire is wrapped with green braided cloth, so as to ensure that the packaging will not be lax in the transportation process. One end of the wire must be clearly marked and the other end left on the outer layer for easy connection by other wires.

Greenhouse special electroplating process iron wire blackening solution:

According to the galvanized iron wire manufacturer, galvanized iron wire is the selection of excellent low carbon steel, through drawing molding, pickling rust removal, high temperature annealing, hot galvanized, cooling and other processes. The following points should be paid attention to in the use of galvanized iron wire:

Aquaculture galvanized welding net this mesh structure is easy to construction, to ensure quality. Compared with the traditional manual binding on site, it can guarantee the quality of the project, shorten the anti-drug construction and shorten the construction period. So now such grids are being used in new villages to strengthen walls and prevent earthquakes.

- 2.65*2.25mm 7 meters per kilogram

- 2. Start running water. Make sure the water is warm so the cat won’t put up a fight.

- Widely used in mining, petroleum, chemical industry, construction, mechanical accessories, protective net, packaging net, barbecue net, barbecue oven net, sintering furnace net, hardware products with net, hardware products with net, arts and crafts with net, vibrating screen net, net basket, food machinery with net, barbecue with net, wall net, grain with net, highway, railway, infrastructure with net.

Post time: 22-07-22The barbed rope is twined and braided to save transportation space. It is usually wound into bundles.

The most common barbed rope is 14*14 and 12*14 wire diameter barbed rope. The 14*14 wire diameter barbed rope is made of 200mm galvanized wire, and the barbed distance can be directly adjusted from 8-12cm. According to the different needs of each customer processing customized. Similarly, the length of each bundle of barbed rope can be cut from 50-250m as required. The 12*14 standard barbed rope is twisted by two different specifications of galvanized wire for 260mm and 220mm barbed wire. Other parameters are roughly the same except for different wire diameters. The price is slightly expensive because the latter uses more materials.

Post time: 14-06-24Greenhouse special electroplating process iron wire blackening solution:

- 4, according to the wire diameter thickness to adjust zinc dipping time

Now it is more used in the binding of the construction industry. Compared with ordinary iron wire, it is softer and has better luster. Use in daily life does not need to carry out maintenance and maintenance, save a lot of time, but also save the cost of maintenance and maintenance. Annealed wire has good stability, good corrosion resistance, greatly prolonging the service life. More kinds, can be selected according to different uses, making annealing wire device is simple, improve the utilization rate of the device. The material properties of annealed wire can meet different processing requirements.

- D, coating adhesion; The zinc layer of the plating parts should be firmly combined with the base metal with sufficient adhesion strength, and will not fall off or bulge after the hammer test.

For the barbed rope products produced by the barbed rope factory, the number of rotating turns between the two thorns is usually 3-5. What is the internal relationship between this and the length of use?

The diameter of cold-drawn wire should conform to the contract, check whether the amount of zinc meets the requirements of the contract, check the tensile strength, and ask the factory to provide the corresponding inspection report. The wire factory introduces that the weight of a single coil of wire of different specifications should not be lower than the volume weight required by the contract, and record the value. No contacts are generated for each reel of wire. If there are contacts, no more than three contacts are generated for each reel. Each contact should be smooth surface treatment, the wire can not be pulled off from the contact, in line with customer packaging requirements.

We can complete the installation of ordinary double-strand barbed rope by using wood shaft or even trees, but the blade barbed rope has high requirements for construction.

- Galvanized iron wire has excellent endurance and elasticity, zinc content can reach 300 grams/square meter. It has the characteristics of thick galvanized layer and strong corrosion resistance. Widely used in construction, handicrafts, silk screen preparation, highway guardrail, commodity packaging and ordinary civilian categories.

- Stainless steel wire drawing is a metal processing (stainless steel) process, is a popular surface treatment technology in stainless steel and aluminum products industry today. It is a wire drawing effect treatment for stainless steel and aluminum products. So galvanized wire and stainless steel wire are two different products. In order to remove the surface film and surface inclusions on the surface of the deposited layer, the defects can be found and treated by conventional techniques. Excess foam is caused by soap and surfactant saponable fats brought into the tank.

The cage door must be open so that the puppy can get out at any time. Once the puppy gets used to the dragon, it will go in without you urging it. Close the door for a few minutes when the puppy is having fun. But keep the crate in a busy area of your home, such as the kitchen. The puppy is relaxed and asleep in the safety of its cage. Cage trained puppies should not be caged for more than two hours during the day (unless you have to, but as soon as you get home from work let the puppy out). After getting used to the crate, the puppy is willing to stay in the playpen. Some dogs can’t stand the small space in a crate, but puppies are less likely to have this problem.

Post time: 19-09-22- 3. The structure of the dog cage should be reasonable

- Now hexagonal mesh is used in a large number of Bridges, piers and bridge buttress inclined plane protection, bridge buttress inclined plane there are many kinds, people according to the inclination of the inclined plane to choose the right hexagonal mesh, and in the case of steep slope, people will use gabion mesh gravity protection wall. As we all know, the use of hexagonal net for protection can protect the natural environment while protecting the bridge, which can not only green the ecological environment, but also prevent soil erosion.

Second: positive and negative twisting rope cost-effective