Clean and easy removal from product material due to the absence of gum.

Moisture Control

What are the alternatives to electrical tape?

Moreover, its color-coded options facilitate easy identification of different wire types, contributing to improved organization and safety in electrical installations Moreover, its color-coded options facilitate easy identification of different wire types, contributing to improved organization and safety in electrical installations

Moreover, its color-coded options facilitate easy identification of different wire types, contributing to improved organization and safety in electrical installations Moreover, its color-coded options facilitate easy identification of different wire types, contributing to improved organization and safety in electrical installations self adhesive pvc insulation tape.

self adhesive pvc insulation tape. This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations

This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations This color code helps electricians and maintenance personnel to quickly recognize and properly handle ground wires, thus promoting safety and compliance with electrical regulations yellow and green electrical tape.

yellow and green electrical tape.

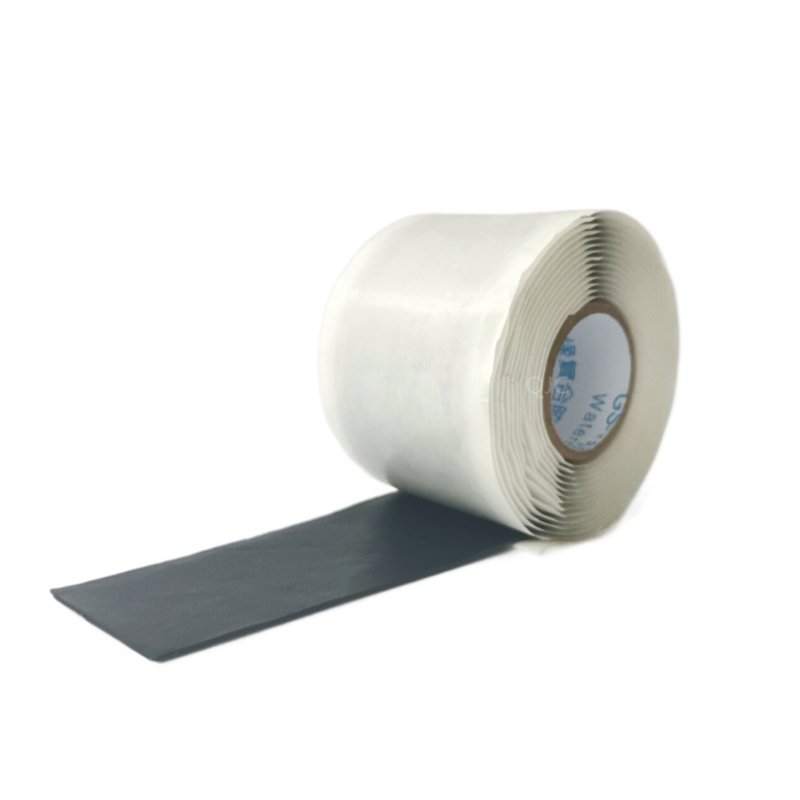

This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern

This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern This makes it ideal for outdoor applications where exposure to moisture, heat, or UV radiation is a concern Enhanced Safety The tape's strong adhesion and durability make it a safer alternative to traditional amalgamating methods, reducing the risk of accidents and injuries Enhanced Safety The tape's strong adhesion and durability make it a safer alternative to traditional amalgamating methods, reducing the risk of accidents and injuries

Enhanced Safety The tape's strong adhesion and durability make it a safer alternative to traditional amalgamating methods, reducing the risk of accidents and injuries Enhanced Safety The tape's strong adhesion and durability make it a safer alternative to traditional amalgamating methods, reducing the risk of accidents and injuries