En conclusión, la compra de cercas de campo representa una inversión que no solo protege tus bienes, sino que también mejora la funcionalidad de tu propiedad. Elegir el tipo y material adecuado es esencial para que la cerca cumpla con su propósito de manera efectiva. Al tomar una decisión informada, puedes estar seguro de que tu inversión valdrá la pena a largo plazo.

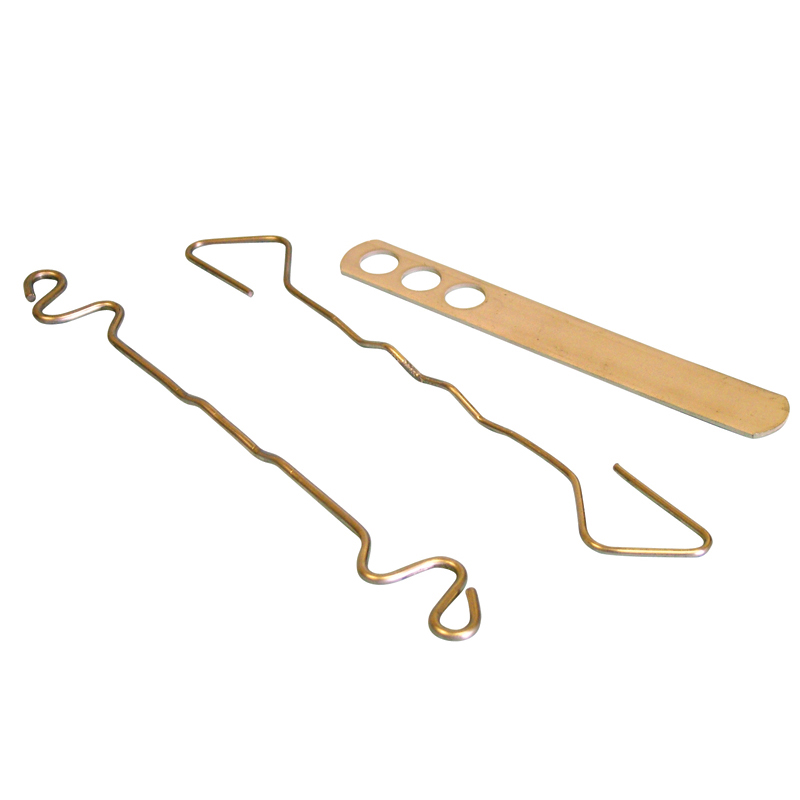

In conclusion, light duty extension springs are essential components in various mechanical applications due to their ability to store energy and maintain tension. Their lightweight design, coupled with durability, makes them ideal for a wide range of industries, including automotive, household, and industrial machinery. By understanding their features and applications, manufacturers and engineers can select the appropriate extension springs to enhance the performance and reliability of their products. As technology continues to evolve, the demand for specialized extension springs is likely to grow, making them an integral part of modern engineering solutions.

Díky svým vlastnostem se drátěné pletivo široce používá v zahradnictví, a to především k ochraně rostlin před škůdci, jako jsou ptáci a hlodavci. Například, pokud pěstujete zeleninu nebo květiny, můžete pletivo použít k vytvoření ochranné bariéry, která zabrání nežádoucím návštěvníkům ve vstupu do vaší zahrady. Tímto způsobem si zachováte zdravé rostliny a zvýšíte úrodu.

bulk chicken wire

These springs operate based on Hooke's Law, which states that the force exerted by a spring is directly proportional to its displacement. This principle allows engineers to predict how much load a spring can handle and how much it will compress under that load.

heavy compression springs

Here, G represents the shear modulus of the material, d is the wire diameter, D is the mean diameter of the spring, and N is the number of active coils

. These parameters help ensure that the selected material and dimensions provide the necessary stiffness without sacrificing durability.The Benefits of Bulk Purchasing

ในสรุป Wholesale H Stakes คือโอกาสที่เต็มไปด้วยความท้าทายสำหรับผู้ประกอบการที่มีแรงบันดาลใจและความมุ่งมั่นในการสร้างสรรค์สิ่งใหม่ การจัดการความเสี่ยงและการพัฒนากลยุทธ์ที่เหมาะสมจะช่วยให้พวกเขาประสบความสำเร็จและเติบโตในตลาดที่มีการแข่งขันสูงนี้ได้อย่างต่อเนื่อง

Types of Coiled Wire Springs: More Than Just a Twist

One primary characteristic of small strong springs is their spring constant, denoted by k, which measures the stiffness of the spring. The higher the value of k, the stronger the spring, meaning it requires more force to achieve a certain displacement. This property is crucial in designing mechanisms that require precise control and reliable operation. For example, in a pen, a small strong spring is used to retract the writing tip, ensuring both functionality and durability.

small strong springs

The Versatility of Brick Ties in Construction

Chain Link Fence for Sale A Reliable and Affordable Fencing Option

Dalším častým využitím drátěného pletiva je konstrukce různých typů kurníků a ohrady pro drůbež. Díky jeho pevnému a odolnému zpracování můžete snadno vytvořit bezpečné a komfortní bydlení pro vaše slepice. Kromě toho, že chrání drůbež před predátory, také jim poskytuje dostatek prostoru pro pohyb a prozkoumávaní okolí.

Sa mga nakaraang taon, ang industriya ng manok sa Pilipinas ay patuloy na umuunlad at lumalakas. Isa sa mga pangunahing aspeto na dapat pagtuunan ng pansin ay ang netong presyo ng mga produkto ng manok. Ang net price, o netong presyo, ay tumutukoy sa kabuuang kita mula sa benta ng manok at mga produktong nagmula dito, matapos ang lahat ng gastos.

Concrete wire mesh is a crucial component in modern construction, often used to reinforce concrete structures and improve their integrity and durability. The cost of concrete wire mesh can vary based on several factors, including material type, gauge, mesh size, and the region in which it is purchased. Understanding these variables can help contractors and builders make informed decisions when budgeting for their projects.