2. Enhanced Adhesion

Use in Food Products

Conclusion

MHEC finds its way into the food industry as a thickening agent, stabilizer, and emulsifier. It is used in a variety of products, including sauces, dressings, dairy products, and gluten-free baked goods. Its ability to retain moisture helps improve texture and extend shelf life, making it a valuable ingredient for manufacturers striving to meet consumer demand for quality and longevity in food products. Furthermore, MHEC is categorized as a Generally Recognized As Safe (GRAS) substance, making it suitable for food applications.

Conclusion

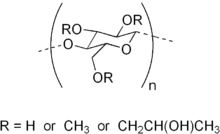

Hydroxypropyl Methylcellulose (HPMC), also known as hypromellose, is a chemically modified cellulose polymer that is widely used in various industries for its unique properties such as water solubility, non-toxicity, and biocompatibility. HPMC is a white to off-white powder that is odorless and tasteless, making it an ideal additive in pharmaceuticals, food, construction, and cosmetic products. This article explores the characteristics, applications, environmental impact, and the future outlook of HPMC.

Hydroxyethyl cellulose is a valuable ingredient across various industries, and finding the right supplier is essential for ensuring product quality and suitability for your specific needs. Whether you opt for online marketplaces, specialized suppliers, or local distributors, consider the factors mentioned to make an informed purchase. With the right hydroxyethyl cellulose at your disposal, you can successfully enhance the quality and performance of your formulations.

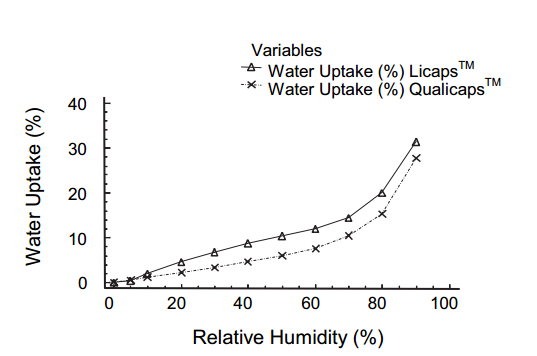

Furthermore, the molecular weight of HEC plays a crucial role in its solubility. Low molecular weight HEC dissolves more readily in cold water, while high molecular weight HEC may require heating or stirring to achieve complete dissolution. The temperature also affects solubility; higher temperatures usually enhance the solubility of HEC in water due to increased molecular motion that facilitates interaction with water molecules.

hydroxyethyl cellulose solubility in water