sewing machine for heavy duty fabric

Latest articles

The HD3000 sewing machine is a versatile and durable tool that can handle a wide range of sewing projects with ease. Whether you are a beginner or a seasoned professional, this machine is sure to meet your sewing needs and exceed your expectations.

sewing machine for heavy duty fabric...

sewing machine for heavy duty fabric 【sewing machine for heavy duty fabric】

Read More

sewing machine for heavy duty fabricSelf-threading sewing machines represent a fantastic advancement in the world of sewing, making it easier and more enjoyable for users of all skill levels. By reducing the difficulty of threading and enhancing efficiency, these machines have transformed how individuals approach their sewing projects. Whether you’re a beginner or a seasoned pro, investing in a self-threading sewing machine can streamline your workflow and elevate your crafting experience. So, explore the options and find the perfect machine for you today!

...

sewing machine for heavy duty fabric 【sewing machine for heavy duty fabric】

Read More

sewing machine for heavy duty fabricAs technology continues to evolve, the world of special sewing expands further. Innovations such as digital fabric printing and computerized embroidery machines allow for limitless possibilities in design and execution. Online communities and tutorials have made learning these advanced techniques more accessible than ever, empowering a new generation of sewists to explore their creativity.

...

sewing machine for heavy duty fabric 【sewing machine for heavy duty fabric】

Read More

sewing machine for heavy duty fabric...

sewing machine for heavy duty fabric 【sewing machine for heavy duty fabric】

Read More

...

sewing machine for heavy duty fabric 【sewing machine for heavy duty fabric】

Read MoreConclusion

sewing machine for heavy duty fabric

...

sewing machine for heavy duty fabric 【sewing machine for heavy duty fabric】

Read More2. Customization Different industries handle various materials. Spout rosettes can be customized to suit specific needs, whether it's a particular size for optimal flow or special features to accommodate certain material characteristics.

sewing machine for heavy duty fabric

...

sewing machine for heavy duty fabric 【sewing machine for heavy duty fabric】

Read MoreMoreover, these machines often have powerful motors that can handle the stiffness of leather, making them robust enough for heavy-duty applications. They are designed to handle various stitch types, including straight, zigzag, and decorative stitches, giving artisans the versatility they need to create intricate designs.

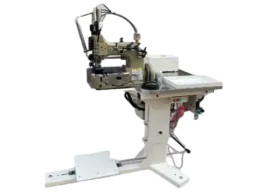

cylinder arm sewing machine leather

sewing machine for heavy duty fabric

...

sewing machine for heavy duty fabric 【sewing machine for heavy duty fabric】

Read More(3) The selection of the needle size and the thickness of the suture should be proportional to the properties of the sewing material, the thickness, softness, and the hardness of the product.

sewing machine for heavy duty fabric

...

sewing machine for heavy duty fabric 【sewing machine for heavy duty fabric】

Read MoreBefore you start sewing, you need to select the appropriate twin needle for your project. Twin needles are available in different widths (the distance between the two needles) and thicknesses. A wider spacing is ideal for techniques like pintucks, while a narrow spacing is better for sewing on knits and lightweight fabrics. Additionally, consider the size of the needle itself; a thicker needle is better for heavier fabrics like denim, while a finer needle works well with more delicate materials.

sewing machine for heavy duty fabric

...

sewing machine for heavy duty fabric 【sewing machine for heavy duty fabric】

Read MorePopular articles

Once your project is complete, take the time to carefully inspect your work. Make any necessary adjustments and give your item a final press with the iron for a polished look. Remember, practice is key in sewing; the more you sew, the more skilled you will become.

1. Control and Precision One of the main benefits of using a hand crank sewing machine for leather is the level of control it offers. As the artisan turns the crank, they can adjust the speed of sewing according to the intricacies of their project, making it easier to navigate curves and details. This level of precision is especially crucial when working with leather, which can be unforgiving if mistakes are made.

- One of the key advantages of stitching automatic machines is their ability to significantly reduce production time. Traditional manual sewing methods are time-consuming and labor-intensive, whereas stitching automatic machines can complete the same tasks in a fraction of the time. This not only helps manufacturers meet tight deadlines but also allows them to increase their output and maximize their profits.

When it comes to sewing, having the right tools can make a significant difference in the quality of your work and your overall experience. For those who engage in heavy-duty projects such as upholstery, thick fabrics, or crafting items that require robust stitching, a heavy-duty sewing machine is essential. But what constitutes a good heavy-duty sewing machine? In this article, we will explore the key features and specifications that set these machines apart and how to choose one that fits your needs.

-

Latest articles

-

1. Durability and Longevity The primary advantage of using thick threads is their resilience. When sewing leather, thicker thread creates a robust seam that can withstand wear and tear over time, making it ideal for products that experience frequent use. Be it a leather jacket or a handbag, thick threads provide the assurance that the seams won’t easily fray or break.

-

-

Future Implications

-

In addition to price, it is also important to consider other features when choosing a pattern sewing machine. Look for machines that offer adjustable stitch length and width, as well as features such as automatic threading, a free arm for sewing cuffs and sleeves, and a variety of presser feet for different sewing techniques. These features will make sewing easier and more efficient, allowing you to create professional-quality garments and accessories.

-

Links

Viscosity and Use Cases

Importance of HPMC in Putty Powder

Role in Pharmaceuticals and Personal Care

3. Impact on Nutrient Absorption There is some evidence to suggest that the presence of HPMC in the gastrointestinal tract may affect the absorption of certain nutrients and medications. As a bulking agent, HPMC may alter the digestive process, potentially leading to reduced bioavailability of certain essential nutrients or drugs.

- - After dissolving, inspect the solution for any undissolved particles or gel formation. If any lumps remain, further mixing may be necessary. A well-dissolved HPMC solution should be smooth and free of visible particles.

1. Construction Industry HPMC is widely used as a viscosity modifier and water-retaining agent in construction materials such as cement, plaster, and tile adhesives. It helps improve workability and extends the setting time of the materials, allowing for better adhesion and improved.

HPMC has found its place in the construction industry, specifically in the formulation of cement-based products such as adhesives, plasters, and mortars. Its use improves workability and enhances the adhesion of these materials. HPMC acts as a water-retention agent, preventing the rapid drying of mortars and allowing more time for application and adjustments. This is especially crucial in construction projects where environmental conditions can affect drying times and material performance.

Moreover, the use of cement bonding additives provides extended service life to constructions. By enhancing the resistance of concrete to water infiltration and chemical attacks, these additives contribute to the longevity of structures. For instance, applications in marine environments or areas with high salinity can benefit significantly from the protective qualities provided by specialized bonding additives, which prevent corrosion of reinforcements and deterioration of the concrete substrate.

The Growing Demand for HPMC

Applications Influenced by Solubility

7. Cool the Solution

In the food sector, HPMC acts as a food additive with emulsifying, thickening, and stabilizing properties. It is commonly used in sauces, dressings, and baked goods, where it helps improve texture and prevent separation. HPMC is particularly valued in gluten-free products, where it mimics the texture provided by gluten, giving baked items a better mouthfeel and structure.

1. Pharmaceutical Industry HPMC plays a crucial role in the pharmaceutical sector, where it is employed as a binder in tablet formulations, a stabilizer in suspensions, and a controlled-release agent. Its ability to form gels and modify drug release rates allows for enhanced bioavailability and therapeutic efficacy.

- Infrastructure Projects In bridges, highways, and tunnels, bonding additives help ensure that the cement withstands heavy loads and adverse weather conditions.

Role in Construction and Personal Care

HPMC is classified as a food additive and is approved for use in various food products. It serves multiple functions, including acting as a thickener, emulsifier, and stabilizer in sauces, dressings, and dairy products. Its ability to retain moisture is particularly valuable in baked goods, where it helps maintain texture and freshness. Additionally, HPMC is utilized in gluten-free products to improve structure and shelf-life.

Moreover, HPMC is used in facial masks and personal care items for its soothing properties, making it suitable for sensitive skin types. Its hypoallergenic nature contributes to its popularity in cosmetic formulations, ensuring safety for consumers.

Redispersible powder, often known as redispersible polymer powder, has become an essential component in various industries due to its unique properties. This specialized powder, typically made from polymer emulsions, offers a range of advantages that enhance the performance of different applications, particularly in construction, adhesives, and coatings. This article delves into the diverse uses of redispersible powder and the benefits it brings to multiple sectors.

The Role of Methyl Hydroxyethyl Cellulose Manufacturers in Modern Industries

Comprehensive Resources for Medical Professionals

-

The production of HPMC involves a series of chemical processes. First, natural cellulose is extracted from plants, usually derived from wood pulp or cotton. The cellulose is then treated with alkali to facilitate the etherification reaction, where the hydroxypropyl and methyl groups are introduced. The end product is then purified, dried, and milled into a fine powder form. This meticulous process ensures that HPMC retains its functional properties and quality for various applications.

Environmental Sustainability

In cosmetics, MHEC is valued for its emulsifying and thickening properties. It is commonly found in creams, lotions, and gels, where it contributes to a smooth texture and stable formulation. The polymer also provides moisture retention, making it an ideal ingredient for skincare products aimed at hydrating and protecting the skin.

Importance of the HPMC SDS

HPMC manufacturers play a crucial role in the quality and reliability of products across multiple industries. By focusing on quality certifications, raw material sourcing, production technology, customization capabilities, reputation, and technical support, businesses can select the right manufacturer to ensure they receive top-quality HPMC. As industries continue to evolve, the importance of reliable HPMC manufacturing will remain essential for innovative and effective product development.

2. Food Industry In the food sector, HPMC serves as a thickener, emulsifier, and stabilizer. It enhances the texture and mouthfeel of various products, including sauces, dressings, and dairy products. Additionally, HPMC is employed in gluten-free baking to improve dough consistency, providing structural integrity without wheat gluten.

1. Direct Communication Buying directly from manufacturers or suppliers can sometimes yield better deals or exclusive promotions.

The incorporation of Hydroxypropyl methylcellulose (HPMC) into gypsum products represents a significant advancement in construction technology. By enhancing workability, prolonging open time, improving adhesion, and promoting sustainability, HPMC plays a crucial role in the development of high-performance gypsum formulations. As the construction industry continues to evolve, the synergy between HPMC and gypsum products will undoubtedly pave the way for innovative and efficient building solutions that meet the demands of modern construction practices.

2. By Viscosity HPMC is available in different viscosity grades, which are suitable for different applications. Low viscosity grades are often utilized in applications requiring less thickness, while high viscosity grades are preferred in formulations where increased consistency is essential. The viscosity is measured in centipoises (cP) and typically ranges from 3,000 cP to over 100,000 cP.

Hypromellose is a white to off-white powder that is odorless and tasteless. One of its key characteristics is its solubility; it readily dissolves in cold or warm water, forming a viscous gel or solution. This property is particularly advantageous in pharmaceutical applications, where HPMC can be used as a binder, thickener, or stabilizer. The viscosity of HPMC solutions can be tailored by adjusting the grade and concentration, allowing formulators to achieve the desired consistency and stability in their products.

The Redispersible Polymer Powder forms a film on the cavity and surface of the mortar, and the polymer film will not disperse again after being exposed to water, which prevents the intrusion of water and improves the impermeability. Special Redispersible Polymer Powder with hydrophobic effect.

3. Construction HPMC is utilized in the construction industry, particularly in tile adhesives, plasters, and grouts. It improves workability, water retention, and adhesion properties, allowing for better performance and durability of construction materials.

In recent years, the significance of Hydroxypropyl Methylcellulose (HPMC) has grown exponentially across various industries, including pharmaceuticals, food, construction, and personal care. From its production at specialized HPMC factories to its application in everyday products, this versatile cellulose derivative has proven to be an essential component in modern manufacturing processes.

In conclusion, redispersible polymer powder is an indispensable component in a myriad of applications across multiple industries. Its ability to enhance the performance of construction materials, adhesives, coatings, and textiles makes it invaluable. As industries continue to evolve and adapt to new challenges, the versatility and advantages offered by RPP will likely see its applications expand even further, solidifying its role as a key ingredient in innovative product formulations.

Propyl Methyl Cellulose (PMC) is a derivative of cellulose, a natural polymer that forms the structural component of plants. This modified cellulose has gained significant attention in various industries due to its unique properties and versatility. In this article, we will explore the characteristics, applications, and significance of Propyl Methyl Cellulose, emphasizing why it is an essential ingredient in pharmaceuticals, food, construction, and personal care products.

In the coatings industry, dispersible polymer powders are critical for producing high-performance paints and coatings

. They improve film formation and enhance durability against weathering and wear. Coatings that incorporate these powders often exhibit superior gloss, color retention, and resistance to cracking and peeling—qualities that are highly sought after in both decorative and protective coatings.HPMC is a white, odorless powder that is soluble in cold water but insoluble in organic solvents. It is produced by the etherification of cellulose, whereby hydroxypropyl and methyl groups are introduced to the cellulose structure. This modification enhances the solubility and stability of cellulose, making HPMC an ideal candidate for various applications. The degree of substitution, which refers to the extent to which the hydroxyl groups of cellulose are replaced by hydroxypropyl and methyl groups, can be adjusted to suit specific requirements.

HPMC is derived from cellulose, a natural polymer, through a chemical process that involves the substitution of hydroxyl groups. This modification enhances its solubility in cold water, a characteristic that distinguishes HPMC from other cellulose ethers. The number “200000” in HPMC 200000 refers to its viscosity, specifically about 2,000,000 mPas when measured in a 2% aqueous solution at 20 degrees Celsius. This high viscosity indicates its ability to provide substantial thickness to formulations, making it ideal for a variety of applications.

The versatility of hydroxyethyl cellulose makes it an invaluable ingredient across multiple industries. From enhancing personal care products to improving food texture and construction materials, HEC plays a significant role in various formulations. As industries continue to evolve and focus on sustainable practices, the importance of HEC is likely to grow, paving the way for innovative applications and improvements in product performance. Its wide-ranging uses underline the significance of hydroxyethyl cellulose as a multifunctional additive that meets the diverse needs of manufacturers and consumers alike.

The construction industry benefits from HPMC's properties as well. It is commonly used in mortar, tile adhesives, plaster, and joint compounds. Its ability to enhance water retention and improve workability makes it an ideal additive in construction materials. HPMC also contributes to the adhesion of materials while preventing cracking and shrinking, which are critical factors for durability in construction projects.

Where to Buy Hydroxyethyl Cellulose A Comprehensive Guide

Hydroxyethyl cellulose plays a vital role in a multitude of industries as a viscosity control agent. Understanding its behavior and the factors that influence its viscosity is essential for formulators aiming to achieve desired characteristics in their products. As industries continue to evolve, the importance of HEC and its properties will likely remain significant, driving innovation and enhancing product performance across various applications. Its versatility and reliability make it an essential component in many formulation processes, allowing for tailored solutions to meet specific needs.

- pH Compatibility Certain HPMC grades may perform better in specific pH environments, making it vital to consider the formulation conditions.

HPMC for Gypsum Enhancing Performance and Application

One of the most convenient ways to purchase hydroxyethyl cellulose is through online marketplaces. Websites such as Amazon, eBay, and Alibaba offer a vast selection of HEC products. Buying online allows you to compare prices, read customer reviews, and often find bulk purchasing options. Be sure to check the seller’s ratings and reviews before making a purchase to ensure product quality.

4. Construction In building materials, HPMC is used as a thickener and water-retaining agent in cement-based compositions, enhancing workability and adhesion.

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose, which is widely used in various industries, including construction, pharmaceuticals, cosmetics, food, and oil drilling. Its unique properties, such as thickening, emulsifying, and stabilizing, make it an invaluable ingredient in many applications. Understanding the price per kilogram of hydroxyethyl cellulose is essential for businesses and individuals who rely on this versatile material.