lock stitch sewing

Latest articles

If you're new to upholstery sewing or unsure of what to look for in a used machine, consider reaching out to local upholstery shops or sewing experts for advice. They can provide valuable insight into which machines are best suited for your projects and how to properly maintain them.

lock stitch sewing...

lock stitch sewing 【lock stitch sewing】

Read More

lock stitch sewing- Leather Goods Artisans crafting leather items, from bags to belts, benefit immensely from the reliable stitching provided by these machines.

...

lock stitch sewing 【lock stitch sewing】

Read More

...

lock stitch sewing 【lock stitch sewing】

Read MoreOne of the most significant advantages of bag making machines is their ability to operate with various materials. From biodegradable options to traditional plastics, these machines accommodate a range of materials that can be tailored to meet environmental standards. As consumers become more environmentally conscious, manufacturers are increasingly adopting biodegradable materials for bag production. Bag making machines equipped with sophisticated technology now allow for the seamless integration of such materials, making it easier for companies to transition towards greener alternatives.

lock stitch sewing

...

lock stitch sewing 【lock stitch sewing】

Read More1. Brother PQ1500SL This machine is often praised for its speed and capability to sew thick materials. It has a powerful motor, a wide table for large projects, and the ability to handle multiple layers of fabric without any hassle.

lock stitch sewing

...

lock stitch sewing 【lock stitch sewing】

Read MoreOne of the primary advantages of the Union Lockstitch Sewing Machine is its reliability. Manufacturers and tailors appreciate its ability to handle various fabrics without compromising on stitch quality. It maintains consistent performance even during long hours of operation, making it an efficient option for those in the textile industry.

union lockstitch sewing machine

lock stitch sewing

...

lock stitch sewing 【lock stitch sewing】

Read MoreIn summary, the serger machine is a powerful tool that significantly enhances the sewing process. Its ability to finish edges, create durable seams, and deliver a professional quality ensures that it remains an indispensable part of any sewing toolkit. Whether you’re a seasoned designer or a sewing novice, understanding how to utilize a serger machine can elevate your projects and broaden your creative horizons. By incorporating this dynamic machine into your sewing practice, you can achieve superior results and enjoy a more efficient workflow.

lock stitch sewing

...

lock stitch sewing 【lock stitch sewing】

Read More...

lock stitch sewing 【lock stitch sewing】

Read More...

lock stitch sewing 【lock stitch sewing】

Read MoreWhen looking for a carpet overlocking machine for sale, several factors should be taken into account to ensure that you make an informed decision

lock stitch sewing

...

lock stitch sewing 【lock stitch sewing】

Read MoreSewing enthusiasts and professionals alike often encounter challenges when working with thick fabrics. Whether it’s upholstery material, multiple layers of denim, or quilt batting, using the right tools is essential for achieving a high-quality finish. One such indispensable tool is the walking foot. This specialized sewing machine attachment has garnered a reputation for revolutionizing the way we handle thick fabrics, making it a must-have for anyone serious about sewing.

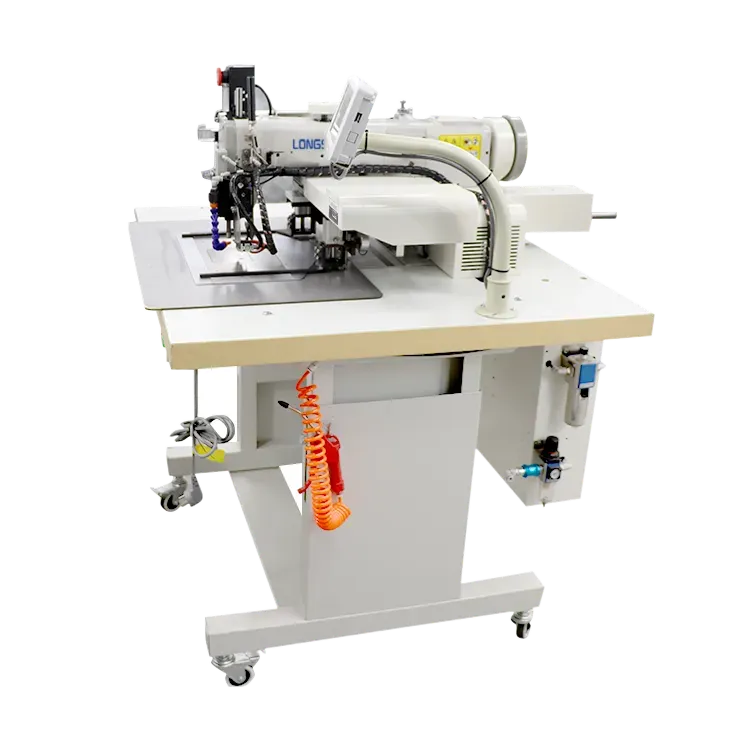

A lock stitch is created by interlocking two threads—a top thread and a bobbin thread. The top thread is fed through the needle and forms a stitch on the front of the fabric. The bobbin thread, located in a lower compartment of the machine, loops up to meet the top thread, forming a secure stitch that is often used for a wide array of sewing applications. This type of stitch is characterized by its tightness and durability, making it suitable for sewing heavier materials such as denim and canvas, while also being gentle enough for lighter fabrics.

In the realm of industrial sewing, cylinder bed sewing machines have carved out their niche due to their unique design and versatility. These machines are particularly favored for sewing cylindrical or tubular items such as sleeves, cuffs, and pant legs. However, when considering the adoption of such equipment, potential buyers often find themselves wondering about the price range and what factors can influence these costs.

- Standardization vs. Customization While standard spout designs may be suitable for many applications, some industries may require customized solutions. Manufacturers often work with clients to develop designs that meet specific operational needs.

Latest articles

-

Links

- discount artificial turf

- Affordable Pricing for Artificial Grass Carpets and Installation Options

- artificial turf estimate

- colored rubber granules

- Exercise Mats for Heavy Weight Training and Home Gym Use

- Different Varieties of Synthetic Grass and Their Unique Benefits

- Creative Ideas for Gym Floor Square Designs and Layouts

- 12x12 Workout Mat for Home Gym Fitness and Exercise Activities

- custom rubber gym mats

- Cost Analysis of Various Running Track Surfaces for Sports Facilities

- Choosing the Right Gym Flooring for Your Weight Room Setup

- Estimating the Cost of Artificial Turf Per Square Foot for Your Project

- Cost Estimation for Turf Field Installation and Maintenance

- Effective Resistance Bands for Enhancing Your Workout Routine and Strength Training

- Best Mulch Mats for Playground Safety and Durability

- Essential Flooring Solutions for Your Home Gym Setup

- Designing a Compact Mini Turf Football Field for Fun and Practice

- artificial grass suppliers

- Affordable Indoor Soccer Turf Options for Sale to Enhance Your Play Area

- Benefits of High Density Rubber Flooring for Durable and Comfortable Spaces

- Current Trends in Rubber Pricing within the Gym Equipment Industry

- Durable Gym Mat Flooring for Intense Workouts and Optimal Performance

- Affordable Turf Solutions for Budget-Friendly Landscaping Projects

- 3 Meter Wide Synthetic Grass for Versatile Landscaping and Outdoor Use

- artificial grass price fitted

- Durable Rubber Floor Mats for Safe and Effective Weightlifting Workouts

- Essential Powerlifting Floor Mats for Enhanced Stability and Performance During Lifts

- Durable and Stylish PVC Flooring Solutions for Your Home Gym

- 1m x 1m gym flooring

- cheap rubber mats for gym

- commercial gym mats

- Calculating the Price of Football Turf per Square Foot for Budgeting

- Choosing the Best Flooring for Your Home Gym Workouts and Comfort

- Durable Gym Mats for Intense Workouts and Increased Comfort During Exercise

- Choosing Durable Rubber Safety Tiles for Enhanced Playground Safety and Protection

- Estimating Costs for Gym Flooring Installation and Materials

- commercial turf installation

- Choosing the Best Gym Mats for Weightlifting Safety and Comfort

- Best Quality Artificial Turf Direct from Manufacturers for Your Project Needs

- cheap flooring for gym

- Benefits and Applications of EPDM Rubber Granules in Various Industries

- Best Garden Mats for Placing Under Swings in Your Backyard

- Cost Analysis of Artificial Grass per Square Metre

- Choosing the Best Synthetic Turf Field for Your Sports Facility Needs

- Choosing the Best Flooring Solutions for Professional Gym Environments and Athletes

- Choosing the Best Synthetic Turf Field for Your Sports Facility Needs

- Creating a Hypothetical Football Field Layout for Fun and Strategy

- Essential Rubber Flooring Options for Your Yoga Studio's Comfort and Performance Needs

- Acquire High-Quality Rubber Flooring for Your Gym at Affordable Prices

- Durable Rubber Exercise Mats for Intense Workouts and Home Gyms