4. Ease of Use Look for machines that are user-friendly, with features like automatic threading, easy bobbin replacement, and intuitive controls. An ergonomic design can also enhance comfort, especially during extended use.

The price of zigzag sewing machines can vary widely depending on the above factors. Entry-level machines are typically priced between $100 to $300. These models often provide basic zigzag functionality suitable for beginners and light sewing tasks. Mid-range machines usually cost between $300 to $700 and include more advanced features, making them suitable for hobbyists and semi-professionals. High-end machines, which may be priced from $700 to over $2,000, are designed for serious sewing enthusiasts and professionals, offering extensive features, durability, and high performance.

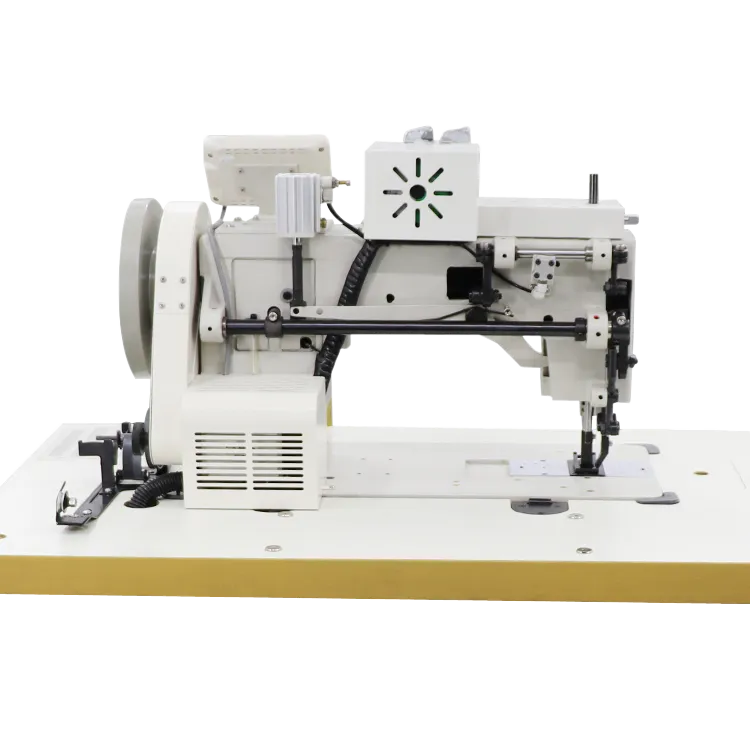

Woven sack bag sewing machines epitomize the blend of technology and practicality in modern manufacturing. Their adaptability and efficiency have made them indispensable in various industries, ensuring that products are packaged securely and sustainably. As manufacturing continues to evolve, these machines will play a vital role in shaping the future of packaging solutions, ultimately driving progress in the global economy.

Additionally, the portability of hand crank leather stitching machines adds to their appeal. Many models are compact and lightweight, making them easy to transport to craft fairs, workshops, or even while traveling. This feature enables leather artisans to demonstrate their skills or work on projects in various settings, fostering a sense of community among fellow crafters.