...

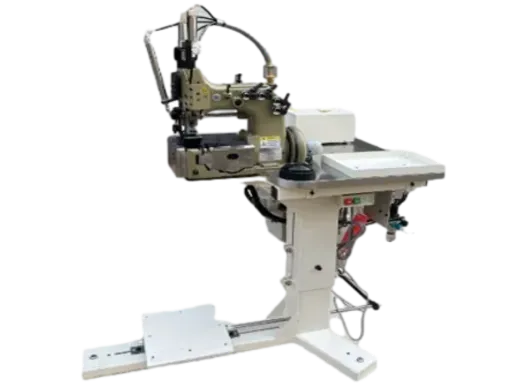

Leather sewing machine 【Leather sewing machine】

Read MoreIt is essential to choose a suitable sewing machine for the job. Lace is a delicate material that needs to be handled carefully, while denim and leather are thick fabrics that require a more robust machine. The choice of the machine affects accuracy, stitch quality, and flexibility. This shows the importance of choosing the right tool for the job.

...

Leather sewing machine 【Leather sewing machine】

Read More...

Leather sewing machine 【Leather sewing machine】

Read MoreMoreover, the design of the single needle bag closer includes robust construction and durable components

. This ensures that the machine can withstand continuous use over extended periods, making it an excellent investment for manufacturers and packaging companies. The ability to perform straight stitching, and sometimes zigzag stitching, adds versatility to the sewing machine, enabling it to cater to various bag types and materials.

...

Leather sewing machine 【Leather sewing machine】

Read MoreVersatility Across Industries

...

Leather sewing machine 【Leather sewing machine】

Read More...

Leather sewing machine 【Leather sewing machine】

Read MoreConclusion

...

Leather sewing machine 【Leather sewing machine】

Read More1. Efficiency One of the most notable benefits of using stitching machines is the speed at which they operate. Skilled artisans can rely on machines for high-volume production without sacrificing the quality of their work. This efficiency is essential for businesses looking to meet demand swiftly while maintaining a competitive edge in the market.

...

Leather sewing machine 【Leather sewing machine】

Read More4. Pressing Seams After sewing, pressing seams opens them up and prepares them for further construction or finishing. For heavy materials, utilizing a steam iron or heat press may yield the best results.

...

Leather sewing machine 【Leather sewing machine】

Read MoreThe Art of Sewing Machines for Fur and Leather

Applications and Advantages

The Double Needle Walking Foot Sewing Machine An Essential Tool for Creatives

Heavy-duty sewing machines provide extra stitch strength, often with triple feed teeth. The maximum stitch length is longer, up to 8mm versus 5mm, to allow bigger basting-type stitches in heavy fabrics. Extra strong stitches prevent seam rupture in heavyweight materials under stress.

Mastering Blind Stitch Upholstery

Proper maintenance and care are essential for keeping your heavy duty sewing machine in top working condition. Regular cleaning is important to prevent dust and lint from building up in the machine, which can affect its performance over time. Use a small brush or vacuum attachment to remove any debris from the bobbin area, feed dogs, and other parts of the machine.

Before starting on your main project, it’s recommended to practice on scrap fabric to perfect your tension settings and stitching technique. This will not only build your confidence but also allow you to make any necessary adjustments to avoid mishaps in your final product.

Understanding Leather as a Material

1. Features and Functionality