...

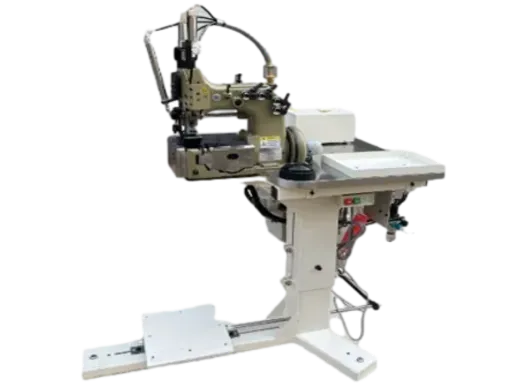

Big bag sewing machine 【Big bag sewing machine】

Read More4. User-Friendly Interfaces Machines equipped with touchscreen displays and intuitive navigation systems often come with higher price tags. These features enhance the user experience, especially for beginners who may find traditional dial settings cumbersome.

Big bag sewing machine

...

Big bag sewing machine 【Big bag sewing machine】

Read MoreThe walking foot is more than just a sewing accessory; it’s a game-changer for anyone working with thick fabrics. Its ability to offer even feeding, reduce puckering, and enhance sewing precision makes it an essential tool for quilters, upholsterers, and garment makers alike. By embracing the walking foot, sewists can elevate their projects, achieve professional results, and enjoy the creative process without the frustrations that often accompany sewing thick materials. Whether you’re a hobbyist or a seasoned professional, the walking foot will undeniably make your sewing journey more enjoyable.

Big bag sewing machine

...

Big bag sewing machine 【Big bag sewing machine】

Read MoreWhen selecting a commercial zig zag sewing machine, various features should be considered to ensure it meets specific needs. Some essential features include

Big bag sewing machine

...

Big bag sewing machine 【Big bag sewing machine】

Read MoreModern PP bag silai machines are equipped with advanced automation features that significantly enhance production efficiency. These machines can perform multiple functions, such as cutting, stitching, and sealing, all in one streamlined process. This not only speeds up production but also reduces labor costs and the chances of human error.

Big bag sewing machine

...

Big bag sewing machine 【Big bag sewing machine】

Read More4. Foot Pedal Control A responsive foot pedal allows for better speed control, which is essential for intricate work.

5 thread overlocker for sale

Big bag sewing machine

...

Big bag sewing machine 【Big bag sewing machine】

Read MoreIn the world of sewing, precision and efficiency are paramount. Whether you’re a beginning hobbyist or an experienced tailor, having the right tools can make all the difference in the quality of your work. One particularly useful feature that has become standard in modern sewing machines is the automatic backstitch. This function not only simplifies the sewing process but also enhances the durability and professionalism of finished projects.

Big bag sewing machine

...

Big bag sewing machine 【Big bag sewing machine】

Read MoreWhat Is A Heavy Duty Sewing Machine?

Big bag sewing machine

...

Big bag sewing machine 【Big bag sewing machine】

Read More

It is a prime example of how even the most seemingly insignificant components contribute to the overall efficiency and safety of machinery It is a prime example of how even the most seemingly insignificant components contribute to the overall efficiency and safety of machinery

It is a prime example of how even the most seemingly insignificant components contribute to the overall efficiency and safety of machinery It is a prime example of how even the most seemingly insignificant components contribute to the overall efficiency and safety of machinery By regularly inspecting and replacing seals as needed, equipment owners can prevent costly downtime and repairs By regularly inspecting and replacing seals as needed, equipment owners can prevent costly downtime and repairs

By regularly inspecting and replacing seals as needed, equipment owners can prevent costly downtime and repairs By regularly inspecting and replacing seals as needed, equipment owners can prevent costly downtime and repairs This can lead to uneven tire wear, vibration, and even steering problems This can lead to uneven tire wear, vibration, and even steering problems

This can lead to uneven tire wear, vibration, and even steering problems This can lead to uneven tire wear, vibration, and even steering problems A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills

A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills A damaged or worn seal can lead to significant issues such as reduced efficiency, increased maintenance costs, and potential environmental hazards due to hydraulic fluid spills