...

Sail making machine 【Sail making machine】

Read More Maintenance and Care

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreWhat is an Auto Cutter Sewing Machine?

...

Sail making machine 【Sail making machine】

Read MoreTo ensure the longevity of your heavy duty handheld sewing machine, regular maintenance is crucial. After each use, it’s a good practice to clean the machine, removing any lint or debris that may have accumulated. Regularly oiling the moving parts can also help maintain smooth functionality. Furthermore, handle your canvas with care, as excessive pulling or tugging can misalign the fabric and damage stitches.

...

Sail making machine 【Sail making machine】

Read MoreOne of the key features of the single needle bag closer is its ease of use. Operators can quickly become proficient in handling the machine, allowing for a swift transition from setup to sealing. The machine typically comes equipped with adjustable speed controls, enabling operators to modify the sewing speed according to their needs. This flexibility is particularly beneficial in high-volume production environments where efficiency can significantly impact profitability.

Understanding the factors influencing auto sewing machine prices is crucial for potential buyers. From selecting the right features to considering the brand and technological advancements, consumers should evaluate their needs and budget carefully. By taking the time to research and compare prices across various platforms, buyers can find the ideal sewing machine that balances quality, functionality, and cost. Whether you’re a seasoned professional or just starting out, the right sewing machine can make all the difference in bringing your creative visions to life.

In conclusion, automatic computerized sewing machines represent a significant advancement in the world of sewing. By merging technology with creativity, these machines have transformed the crafting experience, making it more efficient, precise, and accessible to all. As innovations continue to evolve, the future of sewing looks promising, with endless possibilities for both seasoned professionals and aspiring crafters alike. With the right tools at their disposal, anyone can embark on a journey of creativity and self-expression through the art of sewing.

- Practice If you're new to using a zigzag presser foot, practice on scrap fabric before diving into your main project. This will help you understand the machine's settings and the presser foot’s behavior with your chosen material.

Additionally, these machines contribute to cost-effectiveness. Although the initial investment in a high-speed overlock sewing machine can be substantial, the long-term savings realized through increased output and reduced labor costs often justify this expense. Automated features and user-friendly interfaces in modern models further enhance usability, allowing even novice operators to achieve professional results with minimal training.

One of the key features of heavy-duty bag making machines is their versatility. They can be adjusted to produce bags of different sizes, shapes, and thicknesses, making them suitable for a variety of applications. Whether it's producing large, sturdy sacks for industrial use or smaller, more lightweight bags for retail packaging, these machines can meet the demands of various industries.

3. Sewing Expos and Trade Shows Events dedicated to sewing frequently feature vendors offering machines at discount prices. Attending such events also provides the added benefit of expert demonstrations.

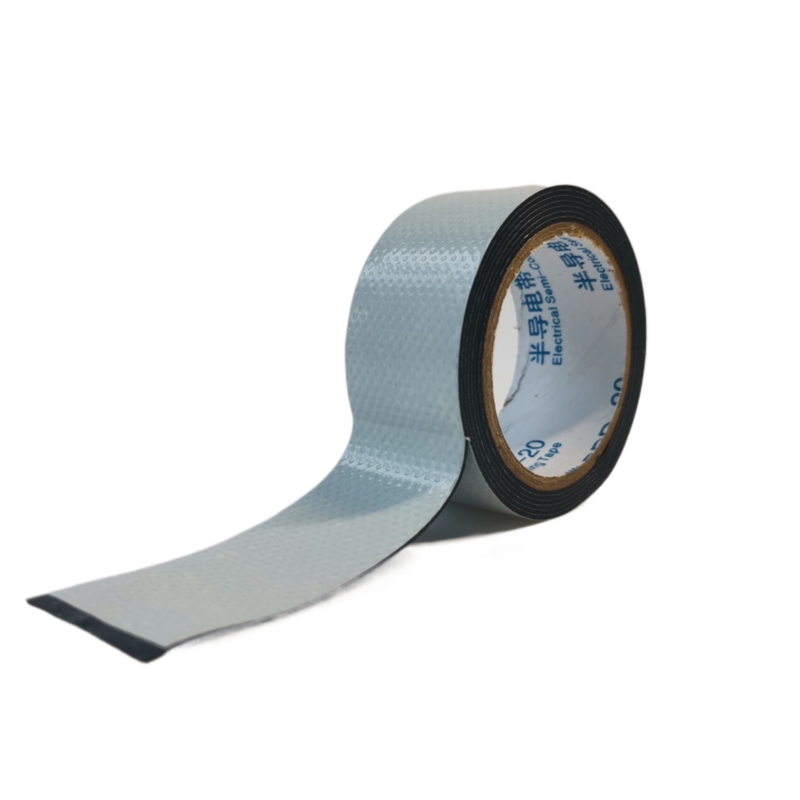

3M rubber tapes have operating temperatures ranging from 176°F (80°C) to 221°F (105°C). Some, Linerless Rubber Splicing Tape 130C and Rubber Splicing Tape 23, have overloads temperatures up to 266°F (130°C). Because of this high heat attribute; there are many industrial settings where it is common to use rubber tape in lower voltage applications to moisture seal, pad and insulate:

As the name implies, synthetic rubber is “formulated rubber” – think coming from the lab, not coming from the tree. Synthetic rubber can broken into three subgroups: Hot-melt, Solvent and Butyl rubber.

4. Crafting and Projects For DIY enthusiasts, Flex Tape serves as a reliable adhesive in various projects, from creating unique art pieces to building structures for outdoor events.

Moreover, butyl rubber tape is non-toxic and safe for use in various applications, including food-related contexts. This makes it a great choice for sealing appliances, packaging, or other areas where food safety is a concern. Its versatility extends to a range of industries, including automotive, construction, electronics, and more.

Its bold design adds structure and clarity to an otherwise busy environment, enhancing the overall workplace aesthetics Its bold design adds structure and clarity to an otherwise busy environment, enhancing the overall workplace aesthetics

Its bold design adds structure and clarity to an otherwise busy environment, enhancing the overall workplace aesthetics Its bold design adds structure and clarity to an otherwise busy environment, enhancing the overall workplace aesthetics black and yellow floor marking tape. It's a cost-effective and easy-to-apply solution compared to painting floors, and it can withstand heavy foot traffic and equipment movement.

black and yellow floor marking tape. It's a cost-effective and easy-to-apply solution compared to painting floors, and it can withstand heavy foot traffic and equipment movement.One of the primary uses of amalgamating rubber tape is in the electrical industry. Electricians rely on this tape to provide insulation and protection for electrical connections and wires. The tape can be easily stretched and wrapped around the exposed wires, creating a tight and secure seal that prevents moisture and dirt from compromising the connection. Additionally, the tape's elasticity allows it to expand and contract with the wires, ensuring a long-lasting and reliable solution.

Acquiring a control box is essential for most residential, commercial, or industrial systems. However, picking the wrong type of control box can be costly, financially and operational-wise. Here are a few considerations to guide you toward selecting the best control box for your system.

3M rubber tapes have operating temperatures ranging from 176°F (80°C) to 221°F (105°C). Some, Linerless Rubber Splicing Tape 130C and Rubber Splicing Tape 23, have overloads temperatures up to 266°F (130°C). Because of this high heat attribute; there are many industrial settings where it is common to use rubber tape in lower voltage applications to moisture seal, pad and insulate:

One example of Flex Tape’s effectiveness is its usage in plumbing repairs. Leaky pipes can cause significant damage if not addressed quickly. Many users have reported successful patching of leaks with Flex Tape, saving time and money on plumbing services. In emergency situations, having Flex Tape on hand can be a lifesaver, providing a quick and efficient solution until a more permanent fix can be implemented.

Key Features

Butyl rubber waterproofing is a popular method used to protect various surfaces from water damage. This type of waterproofing involves the application of a special butyl rubber compound that creates a durable and impermeable barrier against moisture. Whether used in construction projects, industrial applications, or even in residential settings, butyl rubber waterproofing offers a reliable solution for preventing water intrusion and preserving the integrity of buildings and structures.

You can also find many more in-depth studies of what makes a good control box online. They’ll help you get a good idea of how to design component spacing, wireways and more. Next up, we’ll take a look at what some of the different types of control boxes look like and how they function.

Bundle cables to keep them tidy