Sail making machine

Latest articles

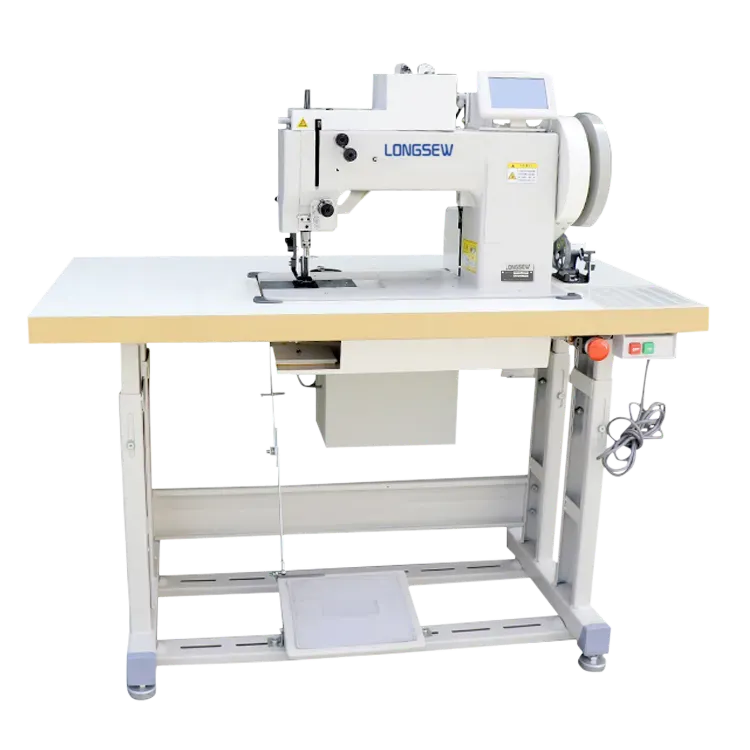

Sail making machineHeavy Duty Computerized Auto Pattern Sewing Machine For Slings LS273-3020

...

Sail making machine 【Sail making machine】

Read More

Sail making machineThe key components of a leather stitching machine include a robust motor, a walking foot mechanism, and specialized needles. The walking foot is crucial as it helps to feed multiple layers of leather evenly, preventing slippage during sewing. This is particularly important when working with thicker leather, which can be challenging to handle manually.

...

Sail making machine 【Sail making machine】

Read More

Sail making machineThe double needle walking foot sewing machine is a specialized sewing machine that features a walking foot and two needles. The walking foot ensures that the top layer of fabric moves evenly alongside the feed dogs beneath, which is particularly useful when working with multiple layers or slippery materials. This mechanism helps to prevent shifting and puckering, resulting in beautifully finished seams.

...

Sail making machine 【Sail making machine】

Read More

...

Sail making machine 【Sail making machine】

Read MoreSail making machine

...

Sail making machine 【Sail making machine】

Read MoreWhat is an Industrial Serger Machine?

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreSail making machine

...

Sail making machine

【Sail making machine】

Read More

Heavy-duty mechanical sewing machines are highly versatile and can be used across many sewing applications. From making durable workwear and outdoor gear to crafting home décor items like curtains and cushions, these machines excel in various projects. For entrepreneurs in the fashion industry, such a machine can facilitate the production of specialized garments designed for rugged conditions, thereby expanding their product lines and catering to niche markets.

Sail making machine

...

Sail making machine

【Sail making machine】

Read More

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreHeavy-duty mechanical sewing machines are highly versatile and can be used across many sewing applications. From making durable workwear and outdoor gear to crafting home décor items like curtains and cushions, these machines excel in various projects. For entrepreneurs in the fashion industry, such a machine can facilitate the production of specialized garments designed for rugged conditions, thereby expanding their product lines and catering to niche markets.

Sail making machine

...

Sail making machine 【Sail making machine】

Read More...

Sail making machine 【Sail making machine】

Read MoreAdjustability for Light Fabrics

Sail making machine

...

Sail making machine 【Sail making machine】

Read MorePopular articles

3. User-Friendly Interface Modern precision zigzag sewing machines are designed with user convenience in mind. Many feature intuitive LCD screens that display stitch options, guides for recommended settings, and easy programming for personalized stitches. This user-friendly interface makes it simple for both beginners and experienced seamstresses to navigate the functionalities of the machine.

- One of the key features of chain stitch sewing is its reversible nature. Because the loops are interconnected, the stitch can be easily undone by pulling on the end of the chain. This makes it a versatile stitch that can be used for temporary basting or seam construction that may need to be taken out later.

5. Extended Work Area With a larger workspace, heavy duty sewing machines allow for easier handling of bulkier projects, making them ideal for quilting enthusiasts or professionals working on larger items.

Regular maintenance and operator training are essential for maximizing the performance of upholstery stitching machines. Proper care can extend the lifespan of these machines, ensuring that they continue to deliver high-quality results. Furthermore, training operators on the latest technologies and features helps in maintaining the productivity levels expected in today’s fast-paced manufacturing environments.

In conclusion, the hi-speed lockstitch sewing machine is a cornerstone of modern textile manufacturing. Its efficiency, consistency, and technological advancements not only boost productivity but also help address sustainability concerns. As the fashion and textile industries continue to evolve, the hi-speed lockstitch machine will undoubtedly play a critical role in shaping the future of garment production, offering opportunities for both innovation and improved operational effectiveness. Embracing this technology is essential for manufacturers aiming to thrive in an increasingly competitive marketplace.

Latest articles

-

-

When selecting a heavy-duty quilting sewing machine, there are a few key factors to consider

-

Don't miss out on this amazing opportunity to own a top-of-the-line heavy-duty sewing machine at a fraction of the price. With its durability, features, and user-friendly design, this machine is sure to become your go-to tool for all your sewing projects. So what are you waiting for? Head over to our website or visit our store today to take advantage of this incredible sale and start sewing like a pro!

-

- Heavy duty sewing machines are suitable for projects such as upholstery, quilting, and making bags, as well as materials like vinyl, suede, and multiple layers of fabric.

-

Maintenance and Best Practices

-

When it comes to sewing leather, a few techniques can make your work easier. For instance, using a walking foot can help prevent the leather from sticking. If you do not have one, placing a piece of tissue paper or wax paper under the leather can also help it glide more smoothly. Additionally, always guide the leather with your hands without pulling it too hard, as this can create tension and result in uneven stitches.

PTFE, which is used in the well-known brand Teflon®, is less commonly used, but it is the preferred material for specific rotating seals in the chemical, food and pharmaceutical industries. This material is notable for having a very low frictional resistance and the best chemical resistance. It can also withstand a very wide range of temperatures in these types of seals; -80 ˚C to 200 ˚C. The shafts on which oil seals with PTFE lips are used require a harder and finer finish. Something like an axle sleeve can also be used to meet this requirement.

2

Necessary to check compatibility with fluids

(See *2)