Its bright color and sleek design make it a stylish addition to any toolbox or workspace Its bright color and sleek design make it a stylish addition to any toolbox or workspace

Its bright color and sleek design make it a stylish addition to any toolbox or workspace Its bright color and sleek design make it a stylish addition to any toolbox or workspace pink electrical tape. This can be particularly useful for professionals who want to add a touch of personality to their work environment.

pink electrical tape. This can be particularly useful for professionals who want to add a touch of personality to their work environment. This durability also means that you won't need to replace it frequently, saving you time and money in the long run This durability also means that you won't need to replace it frequently, saving you time and money in the long run

This durability also means that you won't need to replace it frequently, saving you time and money in the long run This durability also means that you won't need to replace it frequently, saving you time and money in the long run

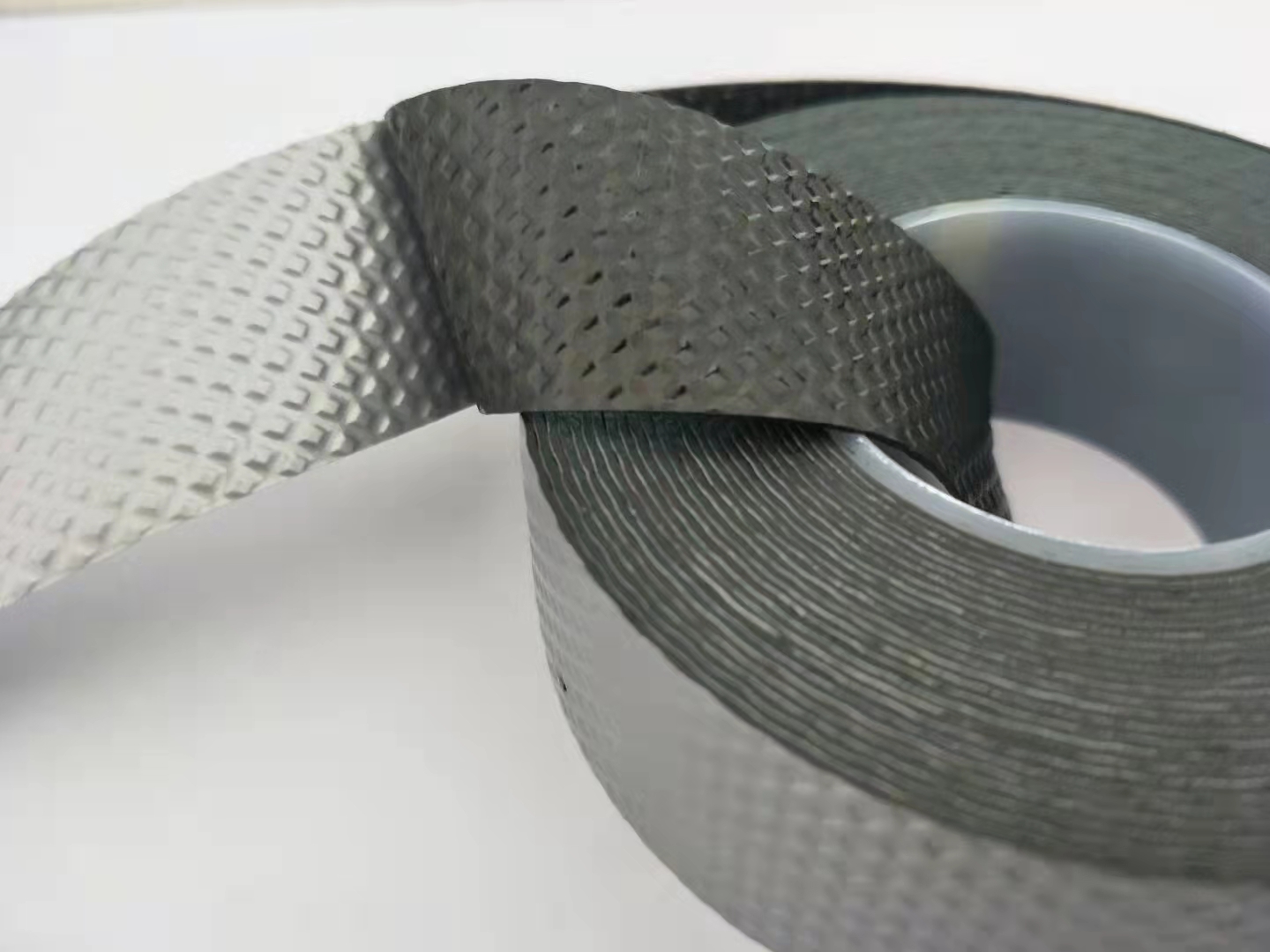

Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues

Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues Rubber, particularly synthetic varieties, can be non-biodegradable, posing disposal issues This makes it suitable for use in harsh conditions where other sealing materials may fail This makes it suitable for use in harsh conditions where other sealing materials may fail

This makes it suitable for use in harsh conditions where other sealing materials may fail This makes it suitable for use in harsh conditions where other sealing materials may fail