If you're a beginner looking to try your hand at leather sewing, a beginner leather sewing machine is a great place to start. These machines are specifically designed to handle the unique challenges of sewing leather, such as its thickness and durability. In this article, we'll discuss the benefits of using a beginner leather sewing machine and provide some tips for getting started.

Advantages of Using a Double Needle Sewing Machine

Advantages of Compound Feed Sewing Machines

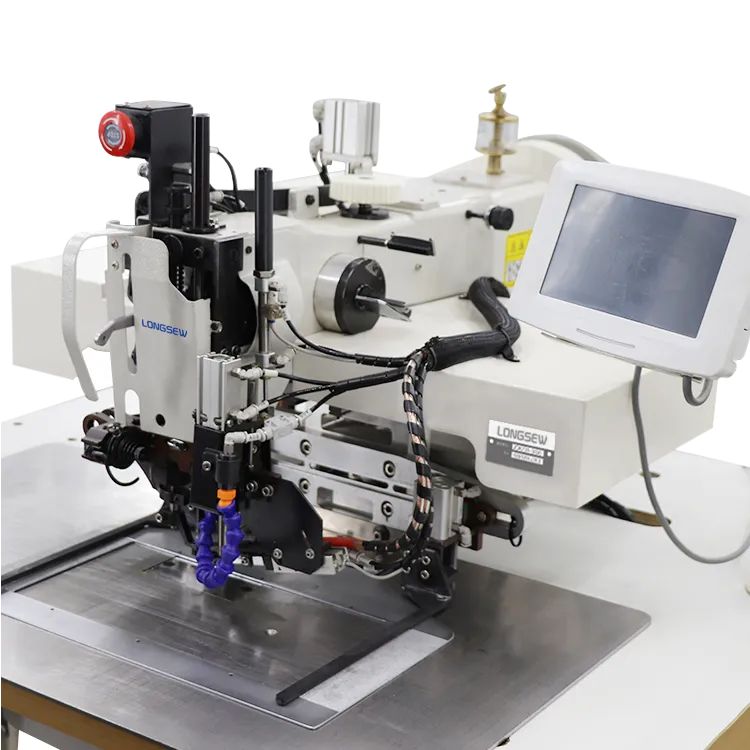

compound feed sewing machine

3. Technology and Features The integration of advanced technology into sewing machines can significantly affect prices. Machines equipped with computerized controls, user-friendly interfaces, and automation capabilities typically have a higher price tag. However, they also offer greater efficiency, precision, and reduced labor costs, which can be beneficial in the long run.