upholstery machine

Latest articles

upholstery machineAs the leatherworking industry continues to evolve, the cylinder arm sewing machine remains an invaluable asset for artisans and manufacturers alike. With their innovative design and robust features, these machines not only enhance productivity but also ensure precision in every stitch. Whether creating high-fashion items or durable goods, the cylinder arm sewing machine provides the tools necessary for success, making it a quintessential element in the toolkit of leatherworkers today. Embracing this technology not only enhances craftsmanship but also allows artisans to push the boundaries of creativity in leather design, ensuring a bright future for the craft.

...

upholstery machine 【upholstery machine】

Read More

upholstery machineFeed Dogs and Fabric Feed

...

upholstery machine 【upholstery machine】

Read Moreupholstery machine

...

upholstery machine 【upholstery machine】

Read More

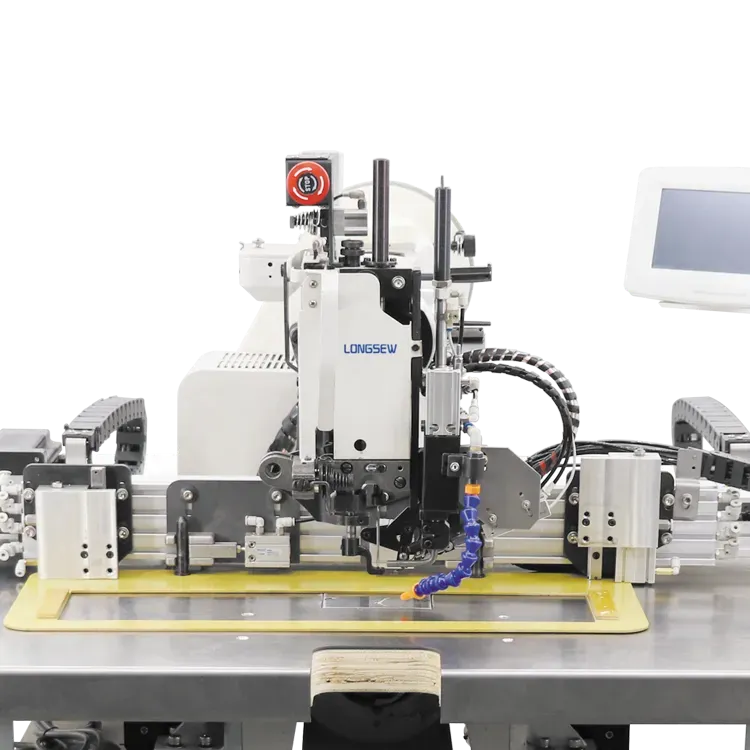

upholstery machineHowever, the adoption of CNC programmable sewing machines is not without its challenges. Initial investment costs can be substantial, which may deter smaller businesses from making the switch. Additionally, reliance on technology necessitates ongoing maintenance and software updates, representing operational costs that organizations must account for. Despite these hurdles, the long-term benefits, such as increased efficiency and reduced waste, often outweigh the initial challenges.

...

upholstery machine 【upholstery machine】

Read More

upholstery machineConclusion

...

upholstery machine 【upholstery machine】

Read MoreAnother advantage of a cylinder arm sewing machine is its speed and efficiency. The machine is designed to sew at a faster pace than a standard sewing machine, making it a valuable tool for high-volume production. Its ability to handle a wide range of materials and sewing tasks makes it a versatile machine for a variety of industries.

upholstery machine...

upholstery machine 【upholstery machine】

Read More

upholstery machineThe Technological Advancements

...

upholstery machine 【upholstery machine】

Read MoreIn conclusion, a shuttle hook case is a critical component of a sewing machine, responsible for ensuring smooth and precise stitching. Regular maintenance and care are crucial for optimal performance, and troubleshooting any issues promptly can help prevent further problems. Choose the right shuttle hook case for your machine and invest in a quality product to enjoy seamless sewing experiences.

upholstery machine...

upholstery machine 【upholstery machine】

Read More- upholstery machine

...

upholstery machine 【upholstery machine】

Read More

upholstery machineAccessories and Parts Availability

...

upholstery machine 【upholstery machine】

Read More

Popular articles

2. Machine Features The features of a single needle sewing machine can vary significantly, affecting its price. Basic models equipped with essential functionalities tend to be more affordable, while machines with advanced features like automatic needle threading, built-in stitches, and adjustable presser feet might be priced higher. Buyers should assess their sewing needs carefully to determine which features are necessary for their projects, ensuring they invest wisely.

The handheld bag closer is a compact and portable sealing machine that provides a quick and effective means of closing bags. Its design typically features a user-friendly interface, allowing operators to seal bags with minimal training or skill. Most models are equipped with an electric motor, heat sealer, or stitching mechanism, enabling them to accommodate various materials, including plastic, paper, and fabric.

Choosing the Right Walking Foot Sewing Machine

5. Reinforce Stress Areas Areas that experience a lot of stress, such as handles or corners, should be reinforced with additional stitching or rivets to enhance longevity.

- Second-Hand Options Buying used machines can be a great way to save money. Platforms such as Craigslist and Facebook Marketplace often have second-hand options. However, ensure the machine is in good working condition before purchasing.