jumbo bag sewing machinery

Latest articles

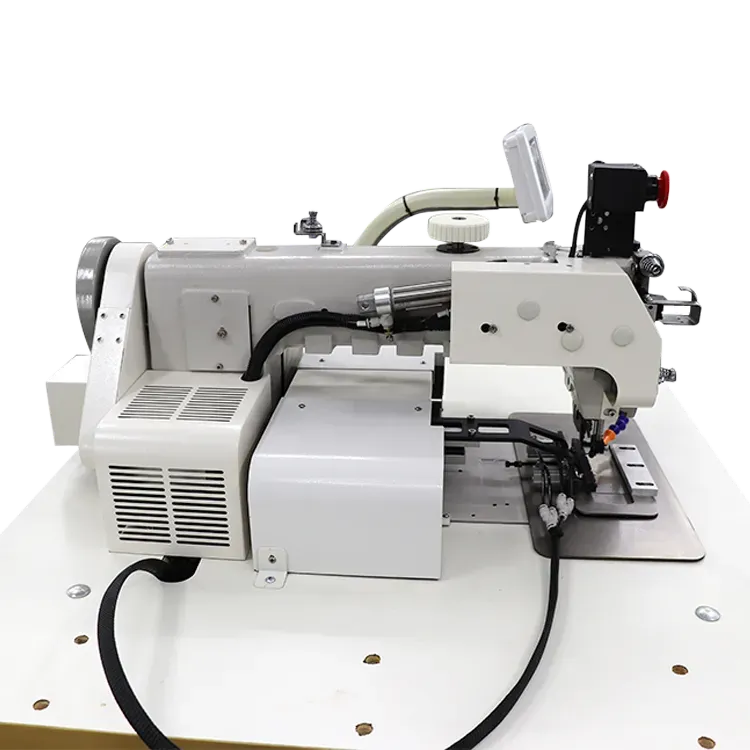

jumbo bag sewing machinery- Efficiency These machines can sew through multiple layers of thick leather quickly and efficiently, saving you time on your projects.

...

jumbo bag sewing machinery 【jumbo bag sewing machinery】

Read More

jumbo bag sewing machineryAt its core, the double needle walking foot machine combines the functionalities of two critical components the double needle and the walking foot mechanism. The double needle allows for the creation of dual rows of stitching, which not only enhances the aesthetic appeal of the finished product but also increases its strength. The walking foot, on the other hand, ensures that all layers of fabric move through the machine evenly, preventing shifting and puckering. This is especially crucial when working with multiple layers of heavy materials, such as leather or denim.

...

jumbo bag sewing machinery 【jumbo bag sewing machinery】

Read More

...

jumbo bag sewing machinery 【jumbo bag sewing machinery】

Read More Needles and Thread Selection

jumbo bag sewing machinery

...

jumbo bag sewing machinery 【jumbo bag sewing machinery】

Read More2. Even Feed When working with multiple layers, a walking foot ensures that all layers are fed through the machine evenly, preventing uneven seams and puckering. This consistency is crucial in leather crafting, where the look and finish of seams can significantly impact the overall quality of the piece.

jumbo bag sewing machinery

...

jumbo bag sewing machinery 【jumbo bag sewing machinery】

Read MoreOne of the key features of the Cub Leather Sewing Machine is its portability. It is small and lightweight, making it easy to transport from one place to another. This means you can take it with you to craft shows, workshops, or even just move it around your own workspace without any hassle.

jumbo bag sewing machinery...

jumbo bag sewing machinery 【jumbo bag sewing machinery】

Read MoreWhen designing a spout rosette, several factors must be taken into account

jumbo bag sewing machinery

...

jumbo bag sewing machinery 【jumbo bag sewing machinery】

Read MoreFurthermore, single needle sewing is often associated with quality and durability

. High-end fashion designers and bespoke tailors frequently embrace this method for constructing garments. By employing single needle techniques, they ensure that the finished product maintains structural integrity while showcasing meticulous attention to detail. The clean seams achieved with this method not only improve the aesthetic appeal of the garments but also enhance their longevity, making them more sustainable in an era increasingly concerned with environmental impact.

jumbo bag sewing machinery

...

jumbo bag sewing machinery 【jumbo bag sewing machinery】

Read Morejumbo bag sewing machinery

...

jumbo bag sewing machinery

【jumbo bag sewing machinery】

Read More

The model of the sewing machine can also impact the price of the shuttle hook. Some sewing machines require specific shuttle hooks that are designed to fit that particular model. These specialized shuttle hooks are usually more expensive than universal ones that can be used with a wide range of sewing machines.

jumbo bag sewing machinery

...

jumbo bag sewing machinery

【jumbo bag sewing machinery】

Read More

...

jumbo bag sewing machinery 【jumbo bag sewing machinery】

Read MoreThe model of the sewing machine can also impact the price of the shuttle hook. Some sewing machines require specific shuttle hooks that are designed to fit that particular model. These specialized shuttle hooks are usually more expensive than universal ones that can be used with a wide range of sewing machines.

jumbo bag sewing machinery...

jumbo bag sewing machinery 【jumbo bag sewing machinery】

Read MoreHistorically, sewing machines have evolved from simple stitching devices to sophisticated instruments capable of intricate designs. The introduction of zigzag stitching was a revolutionary advancement, allowing for greater flexibility in various sewing techniques. Unlike traditional straight stitches, zigzag stitches can accommodate various fabrics, making them ideal for everything from basic garment construction to decorative embellishments.

2. Stitching Power For leather sewing, you need a machine capable of handling heavy materials. Look for machines with a robust motor and stitch length adjustment to accommodate different thicknesses of leather.

In the world of industrial sewing, the quest for efficiency and durability has led to the development of specialized machines that can handle the most challenging materials. Among these, the compound feed heavy duty sewing machine stands out as a vital tool for both manufacturers and hobbyists alike. This article delves into the features, benefits, and applications of this remarkable sewing machine.

Latest articles

-

Moreover, the versatility of the overlock chain stitch extends beyond clothing. It is often used in the production of home textiles, such as curtains and upholstery, where a neat finish and the ability to handle varying fabric types are required. This stitch can also be found in the crafting of accessories, like bags and hats, where strength and elasticity are vital.

-

One of the most critical features to look for in a sewing machine for both fabric and leather is stitch control. The ability to adjust the stitch length and type is vital when switching between materials. For instance, when sewing leather, a longer stitch length (usually between 3-5mm) helps reduce the chances of puncturing the material too many times, which can lead to tearing. In contrast, for lightweight fabrics, a shorter stitch length provides greater control and a more refined finish.

sewing machine for fabric and leather

4. Bernina 570 QE If budget is less of a concern, the Bernina 570 QE is a top-of-the-line machine that delivers superior performance and quality. It features an elaborate threading system, an extensive stitch library, and exceptional stitch quality, making it perfect for detailed quilting and sewing projects.

Links

Simplified Installation with Vertical Inline Centrifugal Pumps

5. Shaft and Bearing Assembly

Wear Factors: Casings can wear down due to the abrasive slurry and need regular inspection and maintenance.

Function: The backplate provides structural support and helps in mounting the pump.

Materials: Liners are often made from high-chrome alloys, rubber, or other wear-resistant materials.

b. Impeller Design:

Understanding the Importance of Impeller Wear Ring Maintenance

Maintenance of sewage pump impellers is also vital for ensuring their longevity and functionality. Regular inspection can help identify wear or damage, and timely replacement of worn-out impellers can prevent pump failures and costly repairs. Moreover, keeping the impeller clean from debris buildup ensures optimal performance.

- Mechanical Seals: Provide a tight seal and reduce leakage.

- Most slurry pump manufacturers provide selection charts that correlate slurry characteristics and operating conditions with suitable pump models.