Sail making machine

Latest articles

Sail making machineIn conclusion, industrial sewing machines and overlockers are vital components of modern textile manufacturing. Their roles in enhancing productivity, ensuring quality, and allowing for creative expression cannot be understated. As the fashion industry continues to evolve, the importance of these machines will only grow, paving the way for advancements in efficiency and design capabilities. Manufacturers must invest in the latest technology and training to keep pace with the demands of the market, ensuring that they remain competitive in an ever-changing landscape.

...

Sail making machine 【Sail making machine】

Read More

...

Sail making machine 【Sail making machine】

Read More Conclusion

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreThings to Keep In Mind When Shopping for a Heavy Duty Sewing Machine

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreBut the best part is, this heavy-duty sewing machine is currently on sale! Take advantage of this limited-time offer and get your hands on this high-quality machine at a discounted price. Whether you are looking to upgrade your current sewing machine or are in need of a reliable backup, now is the perfect time to make the purchase and elevate your sewing experience.

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreThe lock stitch sewing technique involves using a specialized sewing machine equipped with a lock stitch mechanism that secures the threads in place, preventing unraveling and ensuring a strong, reliable seam. This method is preferred for jumbo bags because of its superior strength and durability compared to other sewing techniques.

Sail making machine...

Sail making machine 【Sail making machine】

Read MoreThe impact of automatic machine sewing extends beyond the production line; it also reshapes the workforce dynamics within the industry. While automation may lead to a reduction in the number of manual sewing jobs, it simultaneously creates new opportunities in machine operation, programming, and maintenance. Workers are required to adapt to these changes by acquiring new skills related to operating sophisticated machinery and understanding digital design software. As a consequence, the industry sees a shift toward a more technologically savvy workforce, fostering a culture of continuous learning and adaptation.

Sail making machine

...

Sail making machine 【Sail making machine】

Read MoreSerger machines typically have multiple threads (ranging from 2 to 8) that are used to create different types of stitches, such as a narrow overlock stitch, a rolled hem, or a flatlock stitch. These machines can also be used to add decorative stitches and finishes to fabric.

Sail making machine...

Sail making machine 【Sail making machine】

Read MoreOne of the key advantages of heavy duty sewing machines from China is their high-quality construction. These machines are built to last, with sturdy metal frames and powerful motors that can handle tough sewing tasks with ease. Whether you are sewing through layers of denim, canvas, or leather, a heavy duty sewing machine from China can provide the strength and precision you need to get the job done.

Sail making machine...

Sail making machine 【Sail making machine】

Read MoreWhen it comes to heavy-duty sewing machines, durability and performance are key. These machines are designed to handle thick fabrics, multiple layers, and tough materials with ease. Whether you're sewing upholstery, canvas, denim, or leather, a heavy-duty machine can power through your projects with precision and speed.

Sail making machine...

Sail making machine 【Sail making machine】

Read MorePopular articles

The process of sewing woven sacks involves feeding the fabric into the machine, which then stitches the edges together to form a seamless sack. The machine uses a heavy-duty needle and thread to create strong and reliable seams that can withstand the weight and pressure of the contents inside the sack.

3. Tension Adjustments

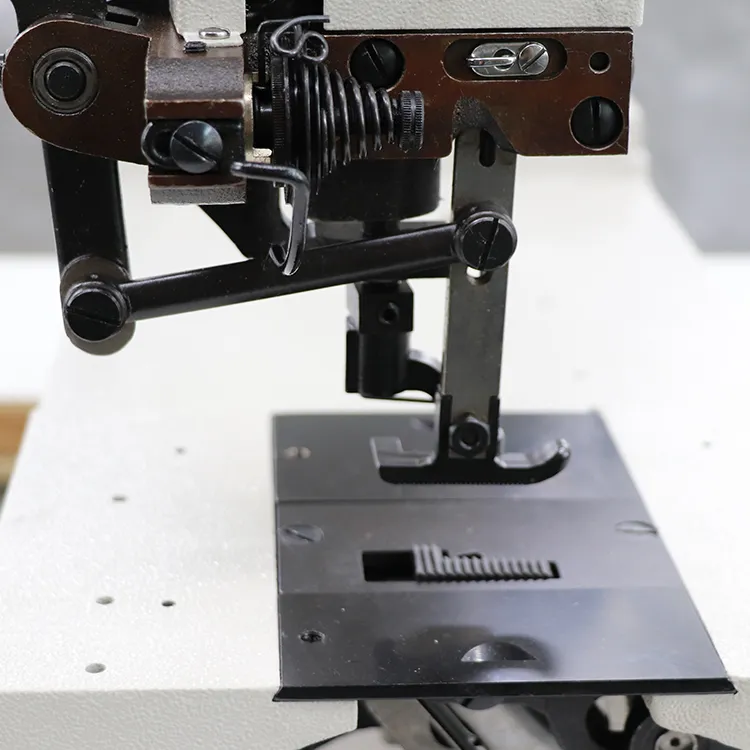

The needles and needle mechanisms are beefed up in heavy-duty sewing machines as well. They use thicker, stronger needles to penetrate heavy fabrics without bending or breaking. The needles are inserted into more heavy duty needle bars and mechanisms to provide stability and vibration resistance at high speeds and with heavyweight needles. This also allows the use of dual needle systems for specialty stitches.

It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects

It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects It also excels in sewing multiple layers, piping, and appliques, providing a professional finish to various sewing projects