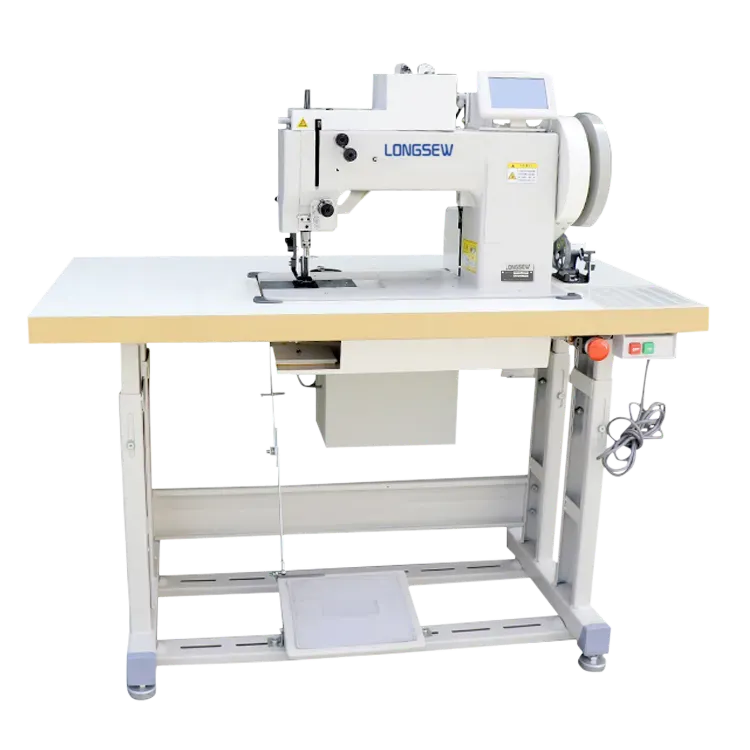

long arm industrial sewing machine

Latest articles

long arm industrial sewing machineOne popular option for a sail making sewing machine is the Sailrite Ultrafeed LSZ-1. This machine is designed specifically for heavy-duty sewing projects, making it ideal for creating and repairing sails. It features a powerful motor and sturdy construction that can handle even the thickest sail fabrics with ease.

...

long arm industrial sewing machine 【long arm industrial sewing machine】

Read More

long arm industrial sewing machineThis feature is especially useful when working with multiple layers of fabric, such as quilts, leather, or sewing intricate patterns. The walking foot mechanism provides uniform tension and consistent stitch quality, resulting in professional-grade finishes that are often hard to achieve with standard machines.

...

long arm industrial sewing machine 【long arm industrial sewing machine】

Read More

long arm industrial sewing machineWhile overlockers are often associated with commercial sewing, they are also incredibly beneficial for home sewers. An overlocker can elevate a hobbyist’s projects, providing a professional finish that significantly improves the appearance of homemade garments. Many modern overlockers come equipped with user-friendly features that make them accessible to sewists of all skill levels, including color-coded threading guides and adjustable stitch settings.

...

long arm industrial sewing machine 【long arm industrial sewing machine】

Read More

long arm industrial sewing machine...

long arm industrial sewing machine 【long arm industrial sewing machine】

Read More

long arm industrial sewing machineTestimonials from Users of Heavy-Duty Sewing Machines

...

long arm industrial sewing machine 【long arm industrial sewing machine】

Read More

long arm industrial sewing machineAdditionally, some sewing machine specials come with bonus offers like free sewing classes, accessories, or extended warranties. These add-ons can significantly enhance your sewing experience and help you get the most out of your new machine. For instance, extra presser feet can expand your sewing capabilities—allowing you to experiment with different techniques like quilting, serging, or blind hemming.

...

long arm industrial sewing machine 【long arm industrial sewing machine】

Read More

...

long arm industrial sewing machine 【long arm industrial sewing machine】

Read More Getting Started with Multi-Needle Quilting

long arm industrial sewing machine

...

long arm industrial sewing machine 【long arm industrial sewing machine】

Read MoreCylindrical bed sewing machines are especially beneficial in the sportswear and knitwear sectors, where tubular garments are predominant. For example, when sewing t-shirts or sweatshirts, the cylindrical bed allows operators to sew along circular features without having to reposition the entire garment multiple times. This capability saves considerable time, increases productivity, and reduces the potential for fabric distortion, which can occur when moving bulky items through a straight stitching path.

long arm industrial sewing machine

...

long arm industrial sewing machine 【long arm industrial sewing machine】

Read MoreConstruction and Durability

long arm industrial sewing machine

...

long arm industrial sewing machine 【long arm industrial sewing machine】

Read MoreExploring the Double Needle Stretch Stitch A Comprehensive Guide

Latest articles

-

One of the main advantages of sewing heavy-duty machines is their ability to handle thick materials without skipping stitches or breaking needles. They are equipped with stronger motors and larger needles that can penetrate through multiple layers of fabric without any issues. This makes it easier for users to work on projects that require sewing through tough materials, such as upholstery, curtains, or even heavy duty bags.

4. Capacity to Handle Heavy Materials Leather is known for its resistance and thickness, which can be a challenge for many sewing machines. Manual leather sewing machines are often designed with robust mechanisms that can handle the heft of leather without jamming or breaking needles. This capability makes them ideal for crafting a wide range of leather products.

Links

- And so, the legend of Shank continued to grow, inspiring new generations of heroes to rise up and protect the natural world from harm. For those who dared to seek him out, Shank remained an enigma – a symbol of hope and courage in a world filled with uncertainty and danger. And though his true nature may never be fully understood, his legacy will live on forever in the hearts of those who have experienced his magic firsthand.

Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces

Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces small air jack hammer.

small air jack hammer. fiberglass chemical tanks. Their lightweight design facilitates easy transportation and installation, reducing labor costs. Furthermore, they require minimal maintenance due to their inherent resistance to wear and tear. Any damage can often be easily repaired, extending the lifespan of the tank.

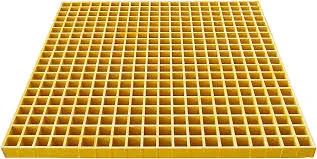

fiberglass chemical tanks. Their lightweight design facilitates easy transportation and installation, reducing labor costs. Furthermore, they require minimal maintenance due to their inherent resistance to wear and tear. Any damage can often be easily repaired, extending the lifespan of the tank.Strong, Lightweight and Corrosion-Resistant

Molded FRP Grating has the strength of steel, but it won’t corrode like steel can.

They are commonly employed in industries such as pharmaceuticals, food processing, wastewater treatment, and chemical storage, where resistance to aggressive chemicals and stringent hygiene standards are paramount They are commonly employed in industries such as pharmaceuticals, food processing, wastewater treatment, and chemical storage, where resistance to aggressive chemicals and stringent hygiene standards are paramount

They are commonly employed in industries such as pharmaceuticals, food processing, wastewater treatment, and chemical storage, where resistance to aggressive chemicals and stringent hygiene standards are paramount They are commonly employed in industries such as pharmaceuticals, food processing, wastewater treatment, and chemical storage, where resistance to aggressive chemicals and stringent hygiene standards are paramount