leather bag stitching machine

...

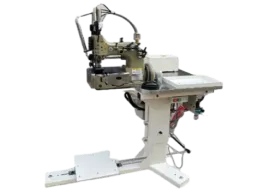

leather bag stitching machine 【leather bag stitching machine】

Read MoreAutomatic bag closer machines are designed to seal bags of various materials, including those used for food, chemicals, textiles, and more. By automating the bag closing process, manufacturers can significantly increase their output while maintaining a high standard of quality. These machines can handle different types of closures, such as heat sealing, ultrasonic sealing, and stitching, making them versatile solutions that can be adapted to various products and industries.

leather bag stitching machine

...

leather bag stitching machine 【leather bag stitching machine】

Read MoreConstruction and Durability

leather bag stitching machine

...

leather bag stitching machine 【leather bag stitching machine】

Read MoreAnother factor to consider when choosing upholstery machine needles is the type of stitching you will be doing. Different needles are designed for specific types of stitches, such as straight stitching, zigzag stitching, or decorative stitching. By selecting the appropriate needle for the type of stitching you will be doing, you can achieve professional-looking results with clean and precise lines.

leather bag stitching machine

...

leather bag stitching machine 【leather bag stitching machine】

Read Moreleather bag stitching machine

...

leather bag stitching machine 【leather bag stitching machine】

Read More The Importance of Industrial Sewing Machines and Overlockers in Modern Textile Manufacturing

leather bag stitching machine

...

leather bag stitching machine 【leather bag stitching machine】

Read MoreProducts made of leather, such as chic handbags, classic leather jackets wallets, and belts, are not typical fabrics. They’re thick and tough, making stitching through them challenging. Also, with leather, it’s there forever. Once you make a hole, it’s there forever, so you need to get the stitch right from the start. That’s where heavy-duty sewing machines come into play. With extra power and consistent pressure, they ensure the needle penetrates the leather smoothly and evenly so using suitable needles for leather, is also essential.

leather bag stitching machine

...

leather bag stitching machine 【leather bag stitching machine】

Read MoreIf you’re in the market for a double needle walking foot sewing machine, there are various avenues to explore. Local sewing machine retailers often carry a range of models, providing a chance to see the machines in action before making a purchase. Additionally, online marketplaces like Amazon, eBay, and specialized sewing websites offer a wide selection of machines at competitive prices.

leather bag stitching machine

...

leather bag stitching machine 【leather bag stitching machine】

Read Mored. Secure the needle in place by tightening the needle clamp.

leather bag stitching machine...

leather bag stitching machine 【leather bag stitching machine】

Read MoreIn conclusion, automatic machine sewing represents a significant leap forward in the textile industry, marrying tradition with innovation. Its ability to enhance production speed, elevate design complexity, and promote sustainability signals a new era for garment manufacturing. As the industry continues to evolve, the focus must remain on balancing technological advancements with the human elements of creativity and craftsmanship, ensuring that the art of sewing thrives in harmony with automation. The future of sewing, much like fashion itself, is poised for exciting transformations, driven by the interplay of technology and design.

leather bag stitching machine

...

leather bag stitching machine 【leather bag stitching machine】

Read MorePopular articles

1. Versatility The double needle setup allows for creative stitching designs. You can create beautiful pintucks and decorative hems that add unique detailing to any project. This makes it an excellent choice for fashion designers looking to add flair to their collections.

The advantages of using a needle feed sewing machine are numerous. First and foremost, this type of machine minimizes fabric shift, which is particularly beneficial when sewing multiple layers of fabric or intricate designs. By ensuring that the materials remain aligned, the needle feed mechanism produces cleaner seams and higher-quality finished products.